Самый популярный бестселлер высокочастотный силовой Нанокристаллический тороидальный сердечник Кольцевой трансформатор из кремниевой стали

- Категория: >>>

- Поставщик: Wuxi Eugenia Tech Co. Ltd.

Сохранить в закладки 1601274768328:

Описание и отзывы

Характеристики

Product Description

Wound cores are commonly used in small and medium-sized transformers (below 1000kVA), transformers, magnetic amplifiers and zero-phase current transformers of leakage protectors, etc.

The materials used for the wound core are soft tape materials such as high magnetic permeability cold-rolled silicon steel sheets and permalloy. The thickness of the silicon steel sheet is 0.18~0.35mm; the thickness of the permalloy strip is 0.03~0.10mm. Taking small and medium-sized transformers as an example, the use of wound cores has the following advantages:

The materials used for the wound core are soft tape materials such as high magnetic permeability cold-rolled silicon steel sheets and permalloy. The thickness of the silicon steel sheet is 0.18~0.35mm; the thickness of the permalloy strip is 0.03~0.10mm. Taking small and medium-sized transformers as an example, the use of wound cores has the following advantages:

1. Under the same conditions, compared with stacked iron cores, the no-load loss of wound iron cores is reduced by 7% to 10%; the no-load current can be reduced by 50% to 75%.

2. The wound core can be made of very thin high-magnetic conductive cold-rolled silicon steel sheets, which can produce transformers with lower losses.

3. The winding core has good craftsmanship, no shear waste, and the utilization rate is almost 100%. Mechanized operations can also be used to eliminate the stacking process, and the production efficiency is 5 to 10 times higher than that of stacked iron cores.

4. The wound core itself is a whole, does not need to be clamped and fixed by supporting parts, and does not have a joint. Therefore, under the same conditions as the stacked core, the transformer noise can be reduced by 5~10dB.

5. The process coefficient of the wound core is about 1.1 for single-phase transformer; it is below 1.15 for three-phase; and for stacked iron core, the process coefficient of small capacity is about 1.45, and the process coefficient of large capacity is also about 1.15. Therefore, the wound core is particularly suitable for small and medium-sized transformers.

Comparison of 3D wound iron core, laminated iron core and flat wound iron core

1. 3D rolled iron core

Three-dimensional rolled iron core: a triangular three-dimensional iron core composed of three single frames of rolled iron cores with the same geometric dimensions.

Three-dimensional wound core transformer: a distribution transformer with a three-dimensional wound core as the magnetic circuit.

Process characteristics: The entire iron core is made up of three identical single frames. The three stems of the combined iron core are arranged in an equilateral triangle shape. Each single frame is made of several trapezoidal strips of material rolled up in sequence. The cross-section of the rolled single frame is close to a semicircle, and the combined cross-section is a quasi-polygon that is very close to a full circle. Trapezoidal strips of different sizes wound around the single frame are obtained by nesting processing with a special folding line cutting machine. This kind of nesting processing can achieve material-free processing, that is, when nesting, the material utilization rate is 100%.

Stacked iron core: It uses a longitudinal shearing production line and a transverse shearing production line to process silicon steel strips into silicon steel sheets of a certain shape, and then stack the silicon steel sheets in a certain way.

There are three disadvantages in the laminated iron core:

The impact of process on loss:

1)Mechanical stress caused by longitudinal shear and transverse shear increases loss

The direction of the magnetic circuit at the corner is inconsistent with the direction of magnetic conduction, resulting in 2)Large magnetic resistance and increased loss.

3)Seams increase losses, especially no-load current

4)The process coefficient is 1.15~1.3

Three-dimensional rolled iron core: a triangular three-dimensional iron core composed of three single frames of rolled iron cores with the same geometric dimensions.

Three-dimensional wound core transformer: a distribution transformer with a three-dimensional wound core as the magnetic circuit.

Process characteristics: The entire iron core is made up of three identical single frames. The three stems of the combined iron core are arranged in an equilateral triangle shape. Each single frame is made of several trapezoidal strips of material rolled up in sequence. The cross-section of the rolled single frame is close to a semicircle, and the combined cross-section is a quasi-polygon that is very close to a full circle. Trapezoidal strips of different sizes wound around the single frame are obtained by nesting processing with a special folding line cutting machine. This kind of nesting processing can achieve material-free processing, that is, when nesting, the material utilization rate is 100%.

2. Laminated iron core

Stacked iron core: It uses a longitudinal shearing production line and a transverse shearing production line to process silicon steel strips into silicon steel sheets of a certain shape, and then stack the silicon steel sheets in a certain way.

There are three disadvantages in the laminated iron core:

1)There are many air gaps formed by seams in the magnetic circuit. This air gap increases the magnetic resistance of the magnetic circuit, thereby increasing the loss and no-load current.

2)The direction of the local magnetic circuit is inconsistent with the high magnetic permeability direction of the silicon steel strip.

3)The sheets are not close enough to each other, which not only reduces the lamination coefficient, but more importantly, increases the noise.

3)The sheets are not close enough to each other, which not only reduces the lamination coefficient, but more importantly, increases the noise.

The impact of process on loss:

1)Mechanical stress caused by longitudinal shear and transverse shear increases loss

The direction of the magnetic circuit at the corner is inconsistent with the direction of magnetic conduction, resulting in 2)Large magnetic resistance and increased loss.

3)Seams increase losses, especially no-load current

4)The process coefficient is 1.15~1.3

Material Grade | 0.2mm | 0.23mm | 0.27mm | 0.30mm |

China Grade | B20R070,B20R075, B20R080 | 23R075,23R080, 23R085,23R090, 23P090,23P095, 23P100 | B27R085,B27R090, B27P090,B27P095, B27P100,B27P110, B27G120,B27G130 | B30P095,B30P100, B30P105,B30P110, B30G120,B30G130 |

Japan Grade | 23R075,23R080, 23R085,23R090, 23P090,23P095, 23P100 | 27R085,27R090, 27P090,27P095, 27P100,27P110, 27G120,27G130 | 30P095,30P100, 30P105,30P110, 30G120,30G130 | |

Korea Grade | 23PHD080,23PHD085, 23PHD090,23PH090, 23PH095,23PH100 | 27PHD085,27PHD090,27PH090,27PH095, 27PH100,27PG110, 27PG120,27PG130 | 30PH095,30PH100, 30PH105,30PH110, 30PG120,30PG130 |

Feature

*Brand: EUCORE

*Core Type:Toroid Core,C core,E core,Rectangular Core

*Manufacturing Capacity:10,000 Pcs Per Day

*Application: Current Transformer,Audio Transformer,Power Supply,Reactor,Potential Transformer

*Design: EU Standard Design Or Custom Design

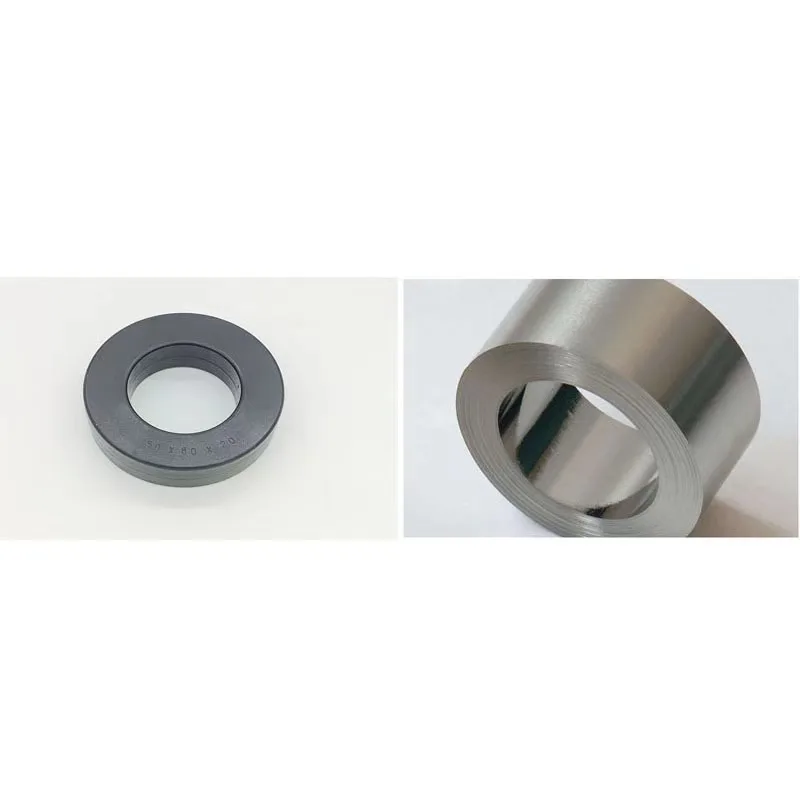

Detailed Images

Slit

Wind

Anneal

Manufacture Specification

Processing Flow:

1.Slit Raw Material 2.Wind 3.Anneal

4.Cut 5. Grinding 6.Test

Best Selling

Company Introduction

Nowdays electricity has been the most important form of power,however over 50% of the planet lacks complete electric

facilities.While some industrial countries like East Asia,North America and West Europe are working on a green energy

revolution,others are troubled by aging basic electric facilities,backward technology and lacking engineer team.

Eugenia Tech is committed to enable customer the abilities to produce distribution transformers and other related electric

products with anvanced processsing skills.Product design,raw material source ,machine source and on site technical support are its main buiness.

facilities.While some industrial countries like East Asia,North America and West Europe are working on a green energy

revolution,others are troubled by aging basic electric facilities,backward technology and lacking engineer team.

Eugenia Tech is committed to enable customer the abilities to produce distribution transformers and other related electric

products with anvanced processsing skills.Product design,raw material source ,machine source and on site technical support are its main buiness.

Our Services & Strength

Eugenia Tech provide customers with transformer drawings,cores,conductors,insulators,bushings and other accessories.Based on its experienced technical team and global cooperation projects,customers can rely on us to source all parts they need and technical supports on their domestic development requirments from their local grid companies.

FAQ

What Can Eugenia Tech Can Help You?

Q1: Do you support custom design?

A1: Yes,we can own technical team to help develop prototype according to customers' design.

Q2: Do you have a material specification sheet?

A2: Yes,you can contact our staff to get it.

Q3: Do you have a company brochure?

A3: Yes,we can send it to you by commercial email.

A3: Yes,we can send it to you by commercial email.

Q4: Do you have a customer in our local market.

A4: Probably yes,but our customers are not always open to share their information.

A4: Probably yes,but our customers are not always open to share their information.

Q5: Can I get a sample?

A5: Yes,but firstly we have to settle down technical details first.

A5: Yes,but firstly we have to settle down technical details first.

Q6: Do you have UL or Reach?

A6: It depends,we have UL for insulating material and ROHS for other products.

A6: It depends,we have UL for insulating material and ROHS for other products.

Q7: What is your MOQ?

A7: It depends. We prefer to find a afforable shipping solution according to samples' sizes and weight.

A7: It depends. We prefer to find a afforable shipping solution according to samples' sizes and weight.

Q8: Do you have aftersale service?

A8: Yes,our team have a face to face meeting with our customer almost every year.

A8: Yes,our team have a face to face meeting with our customer almost every year.

Похожие товары

Настраиваемый 105 мм/125 мм тороидальный трансформатор тока Железный сердечник H10 мм Нанокристаллический промышленный Магнитный стержневой изоляционный материал

Высокотехнологичный масляный трансформатор мощностью 10 МВА, распределительный трансформатор 33/0,4 кВ

Оптовая продажа, мощный магнит, неодимовая монета, супер N30-N52H/SH, диаметрально Намагниченный диск, магнит NdFeB

23,86 ₽ - 54,22 ₽

Индивидуальные Многоконтактный разъем Кольцевой магнит

Индивидуальные Многоконтактный разъем Кольцевой магнит

Aiqi 20*3 мм ферритовый постоянный магнит диск магнитное кольцо Круглый торт черный магнит полные характеристики сильный магнит

1,09 ₽ - 3,26 ₽

Высокое качество эпоксидное покрытие на основе ФЭ трансформатор тороидальный железный порошок кольцо сердечник заводская цена

Новые поступления

Новинки товаров от производителей по оптовым ценам

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $

Съемная пластиковая ручка штукатурка строительный инструмент для отделки бетона с помощью меток

SHIDU U30 двойной беспроводной Перезаряжаемый Профессиональный UHF микрофон караоке с

39,90-57,40 $

1688 закупка Taobao дропшиппинг агент по покупке онлайн-покупки Китай в Испания Румыния Литва от двери до ddp servic

1 $

OEM стираемая зеленая пластиковая клипса с держателем для ручки магнитная футбольная тренировочная

2-2,80 $