Полностью автоматическая машина для Розлива Чистой Воды

- Категория: >>>

- Поставщик: Henan Zhong Yi Long Machinery Equipment Co. Ltd.

Сохранить в закладки 1601275030175:

Описание и отзывы

Характеристики

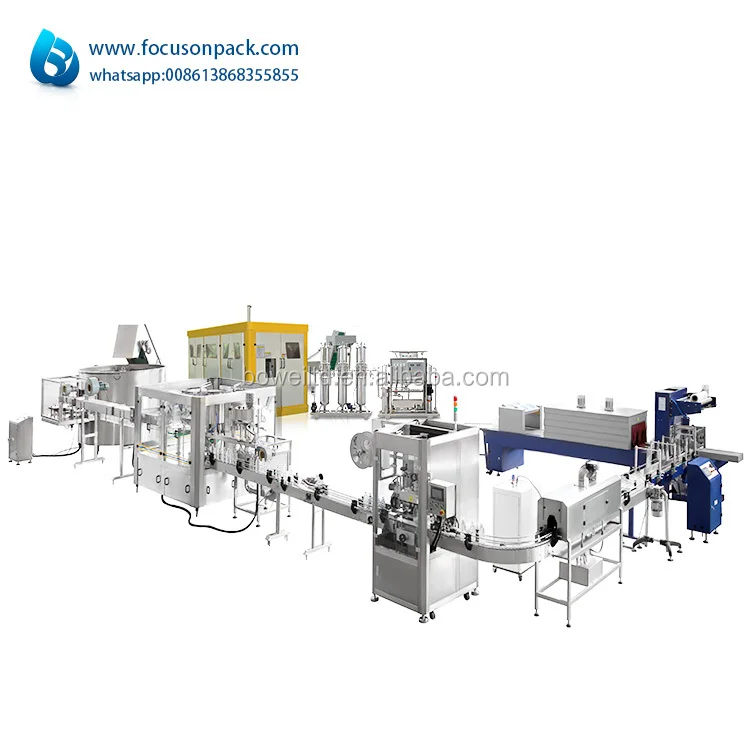

Complete Fully Automatic Pure water bottling production complete line filling machine Factory price

Success in water beverage production requires focus on maximum output and efficiency, with commitment to hygiene, food safety and cost optimisation. Whether you're producing still or sparkling water, our unmatched expertise helps you achieve more with extensive technical knowledge and packaging capabilities.

Products Description

Water Treatment System

Water treatment equipment refers to a series of machines and processes used to remove impurities and contaminants from water,making it safe for human consumption or other industrial uses. The advantages of water treatment equipment include:

1. Safe and reliable: Water treatment equipment ensures that the water being used is free of harmful impurities and contaminants,providing a safe and reliable source of water for households, industries, and other applications.

2. Cost-effective: By removing impurities and contaminants from water, water treatment equipment can help reduce the cost of water treatment and distribution, making it a cost-effective solution for both individuals and businesses.

3. Environmentally friendly: Water treatment equipment helps reduce the negative impact of water pollution on the environment. By treating water before it is discharged, it helps prevent water pollution and preserve natural resources.

4. Energy-efficient: Many water treatment equipment use energy-efficient technologies, reducing the amount of energy required to treat water, and thus reducing the carbon footprint of the treatment process.

5. Customizable: Water treatment equipment can be customized to meet the specific needs of different applications and water sources, ensuring that the equipment is effective and efficient.

Overall, water treatment equipment is an essential investment for any business or individual looking to ensure safe and reliable access to clean water.

1. Safe and reliable: Water treatment equipment ensures that the water being used is free of harmful impurities and contaminants,providing a safe and reliable source of water for households, industries, and other applications.

2. Cost-effective: By removing impurities and contaminants from water, water treatment equipment can help reduce the cost of water treatment and distribution, making it a cost-effective solution for both individuals and businesses.

3. Environmentally friendly: Water treatment equipment helps reduce the negative impact of water pollution on the environment. By treating water before it is discharged, it helps prevent water pollution and preserve natural resources.

4. Energy-efficient: Many water treatment equipment use energy-efficient technologies, reducing the amount of energy required to treat water, and thus reducing the carbon footprint of the treatment process.

5. Customizable: Water treatment equipment can be customized to meet the specific needs of different applications and water sources, ensuring that the equipment is effective and efficient.

Overall, water treatment equipment is an essential investment for any business or individual looking to ensure safe and reliable access to clean water.

Contact us today to learn more about our water treatment equipment and how it can benefit you.

333

Bottle Blow Molding Machine

Blowing machines are essential equipment in the production of plastic bottles, for various beverages, including water, juice, and soda. If you are looking to purchase blowing machines on Alibaba , here are some of the advantages to consider:

Variety of Models: we offers a wide range of blowing machines from different manufacturers, providing you with a variety of options to choose from based on your specific needs and requirements. You can select from manual, semi-automatic, and fully automatic models, depending on your production volume and budget.

High-Quality Components: the blowing machines are made with high-quality components, ensuring that they are durable, reliable, and efficient. These machines are designed to withstand heavy usage and provide consistent performance over time.

Competitive Pricing: we offers competitive pricing on blowing machines, making it an affordable option for businesses of all sizes. You can compare prices and features from different suppliers to find the best deal that meets your needs.

Warranty and Support: we offer warranty and support on our products, providing you with peace of mind in case of any issues or defects. You can also contact us for technical support or maintenance, ensuring that you can get the most out of your investment.

zhongyilong machine offers a range of advantages when it comes to purchasing blowing machines. You can find a variety of models, high-quality components, competitive pricing, warranty and support . By considering these advantages, you can make an informed decision and find the best blowing machine for your business needs.

Variety of Models: we offers a wide range of blowing machines from different manufacturers, providing you with a variety of options to choose from based on your specific needs and requirements. You can select from manual, semi-automatic, and fully automatic models, depending on your production volume and budget.

High-Quality Components: the blowing machines are made with high-quality components, ensuring that they are durable, reliable, and efficient. These machines are designed to withstand heavy usage and provide consistent performance over time.

Competitive Pricing: we offers competitive pricing on blowing machines, making it an affordable option for businesses of all sizes. You can compare prices and features from different suppliers to find the best deal that meets your needs.

Warranty and Support: we offer warranty and support on our products, providing you with peace of mind in case of any issues or defects. You can also contact us for technical support or maintenance, ensuring that you can get the most out of your investment.

zhongyilong machine offers a range of advantages when it comes to purchasing blowing machines. You can find a variety of models, high-quality components, competitive pricing, warranty and support . By considering these advantages, you can make an informed decision and find the best blowing machine for your business needs.

3 in 1 Full Automatic Water Filling Machine For Mineral Water

Complete drinking mineral water bottling production line / pet bottle pure water filling capping plant machineA complete water line solution from Nancheng Machine leverages our knowledge of the entire water bottling process, from minimising waste of resources, to ensuring that your bottle is durable and attractive to consumers. With everything centred around one supplier, you get wide-ranging expertise, line equipment and ongoing services. This ensures high quality and efficiency from packaging to equipment, fast ramp-up and beyond.

Main Features

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this

enable the change the bottle-shaped become easier.

2.Filling way useing the gravity or micro pressure filling,make the speef is faster and more efficient.

3. The machine is easy to change the shape of the bottles,which can be done by changing the thumb wheel without adjusting the

height of the machine .The filling water machine case and the parts contacting with the materials are made of stainless steel

which ensures the good external look and easy washing.

4. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of

bottle mouth to avoid secondary pollution.

5. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

6. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

7. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's

Mitsubishi, France Schneider, OMRON.

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this

enable the change the bottle-shaped become easier.

2.Filling way useing the gravity or micro pressure filling,make the speef is faster and more efficient.

3. The machine is easy to change the shape of the bottles,which can be done by changing the thumb wheel without adjusting the

height of the machine .The filling water machine case and the parts contacting with the materials are made of stainless steel

which ensures the good external look and easy washing.

4. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of

bottle mouth to avoid secondary pollution.

5. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

6. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

7. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's

Mitsubishi, France Schneider, OMRON.

Number of washing positions | Number of filling nozzles | Number of screw caps | Rated output (500ml) | Installed capacity (KW) | Dimensions (length × wide × High)mm |

8 | 8 | 3 | 3000BPH | 3 | 1900×1420×2000 |

16 | 16 | 6 | 4000BPH | 3.5 | 2200×1600×2300 |

18 | 18 | 6 | 6000BPH | 4 | 2450×1900×2300 |

24 | 24 | 8 | 10000BPH | 4.8 | 2750×2180×2300 |

32 | 32 | 10 | 12000BPH | 7.6 | 4000×2300×2300 |

40 | 40 | 12 | 15000BPH | 8.3 | 4550×2650×2300 |

50 | 50 | 15 | 20000BPH | 9.6 | 5450×3210×2300 |

Product details

Washing Part.

Carefully designed bottle washing machine bottle clip does not touch the screw part of the bottle mouth, effectively prevent bottle mouth pollution.Filling production line conveyor system adopts star wheel transport, stable transport, conveyor wheel stainless steel material.Chassis flushing pipes are made of 304 stainless steel for flushing water filtration systems.

Filling Part.

The equipment is equipped with

automatic flow detection, pressure detection, after purging residual liquid detection, wine spear open detection and other detection functions, and with station alarm.Filling using CO2 pressure, pressure holding low pressure difference fully closed filling method, filling volume using imported flow meter detection, can ensure the filling of wine afterlow foam, low consumption, accurate filling volume.

The upper cover is detected by photoelectric and proximity switches to send out signals to ensure accuracy and no operation.Screw

cap using - servo cap, stable, reliable and efficient.

cap using - servo cap, stable, reliable and efficient.

The conveying is smooth, there is no relative movement between the material and the conveyor belt, which can avoid the damage to

the conveying material, the structure is simple, easy to maintain, the energy consumption is small, the use cost is low.

the conveying material, the structure is simple, easy to maintain, the energy consumption is small, the use cost is low.

Other capping styles can also be made as follows: aluminum cap, imperial cap, ring pull cap, etc

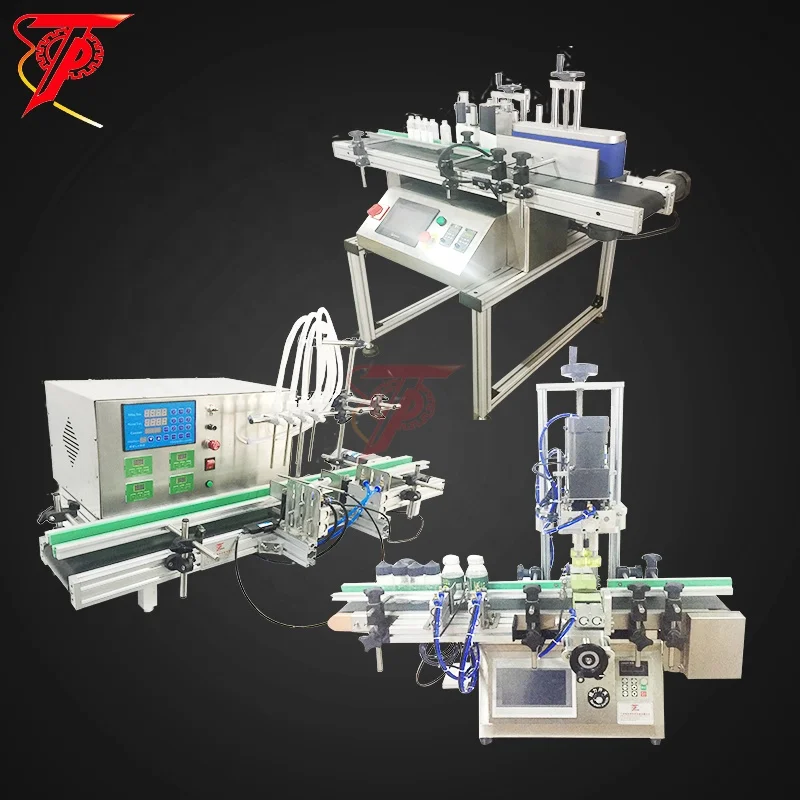

Labeling Machine

Plastic labeling machines are essential equipment in the packaging industry, used to apply labels to various plastic products, including food containers, beverage bottles, cosmetic packaging, and containers. Here are some of the advantages of using plastic labeling machines in the packaging process:

Efficiency: Plastic labeling machines are designed to be fast and efficient, allowing for high production volumes and faster turnaround times. This is particularly important in a production environment where time is money.

Accuracy: Plastic labeling machines are highly accurate in applying labels to products, ensuring that each label is placed in the correct position and orientation. This results in consistent product labeling and reduces the risk of product waste.

Consistency: Plastic labeling machines produce labels with consistent quality, which is essential for maintaining the reputation of a brand. The uniformity of the labels ensures that the product is consistent in appearance and branding, which is important for customer satisfaction.

Reduced Costs: Using plastic labeling machines can reduce production costs significantly. The machines are designed to be energy-efficient, reducing the cost of electricity required for the production process. Additionally, the use of automation reduces the need for manual labor, which can be costly in terms of both time and money.

Safety: Plastic labeling machines are designed with safety features that minimize the risk of accidents. The machines are equipped with safety sensors and interlocks that prevent the machine from operating when there is an obstacle in the line, reducing the risk of injury to operators.

plastic labeling machines offer a range of advantages in the packaging industry. They are efficient, accurate, consistent, cost-effective, and safe。

Efficiency: Plastic labeling machines are designed to be fast and efficient, allowing for high production volumes and faster turnaround times. This is particularly important in a production environment where time is money.

Accuracy: Plastic labeling machines are highly accurate in applying labels to products, ensuring that each label is placed in the correct position and orientation. This results in consistent product labeling and reduces the risk of product waste.

Consistency: Plastic labeling machines produce labels with consistent quality, which is essential for maintaining the reputation of a brand. The uniformity of the labels ensures that the product is consistent in appearance and branding, which is important for customer satisfaction.

Reduced Costs: Using plastic labeling machines can reduce production costs significantly. The machines are designed to be energy-efficient, reducing the cost of electricity required for the production process. Additionally, the use of automation reduces the need for manual labor, which can be costly in terms of both time and money.

Safety: Plastic labeling machines are designed with safety features that minimize the risk of accidents. The machines are equipped with safety sensors and interlocks that prevent the machine from operating when there is an obstacle in the line, reducing the risk of injury to operators.

plastic labeling machines offer a range of advantages in the packaging industry. They are efficient, accurate, consistent, cost-effective, and safe。

Packing Machine

Once your beverage product has been filled and the bottle has been labelled, the primary package is gently transferred using

conveyors to its secondary packaging process. The final result is the package the customer sees at the point of sale,

to grab their attention. These packs ensure protection from elements such as weather, pressure and temperature changes. Whether you choose shrink-printed film, nested packs or wraparound cartons, Our Machine packers gently feed bottles to ensure durable and cost-effective packs.

Benfits.

1 / Pack consistency and quality

2 / Gentle and precise infeed configuration

3 / Flexible handling of multiple SKUs

4 / Automatic pack and raw material changeovers

5 / Heat, glue, carton and film optimisation

conveyors to its secondary packaging process. The final result is the package the customer sees at the point of sale,

to grab their attention. These packs ensure protection from elements such as weather, pressure and temperature changes. Whether you choose shrink-printed film, nested packs or wraparound cartons, Our Machine packers gently feed bottles to ensure durable and cost-effective packs.

Benfits.

1 / Pack consistency and quality

2 / Gentle and precise infeed configuration

3 / Flexible handling of multiple SKUs

4 / Automatic pack and raw material changeovers

5 / Heat, glue, carton and film optimisation

We can customer-built the robot palletizing solution specially to meet different needs. We have rich experience in cartons, bags,plastic bags and other products palletizing solutions. We choose the plan not only considering the customers’ requirements, but also focus on long operating life, low energy consumption and maintenance in the future.

application

OEM/ODM

Supply bottle&label design and factory layout for free!

We are specialized in providing filling and packaging machines for various liquids.

In order to provide you with appropriate solutions and accurate quotations, we need to know:

1. What kind of liquid?

2. Bottle type (material and shape) and size?

3. Expected filling volume (bph)?

4. Expected functions of the machine (bottle washing, filling, capping? Semi-automatic or fully automatic?)

5. Other functions such as labeling, printing date, packaging, etc?

6. Available layouts?

7. Available voltage/Hz/phase?

8. Other requirements.

In order to provide you with appropriate solutions and accurate quotations, we need to know:

1. What kind of liquid?

2. Bottle type (material and shape) and size?

3. Expected filling volume (bph)?

4. Expected functions of the machine (bottle washing, filling, capping? Semi-automatic or fully automatic?)

5. Other functions such as labeling, printing date, packaging, etc?

6. Available layouts?

7. Available voltage/Hz/phase?

8. Other requirements.

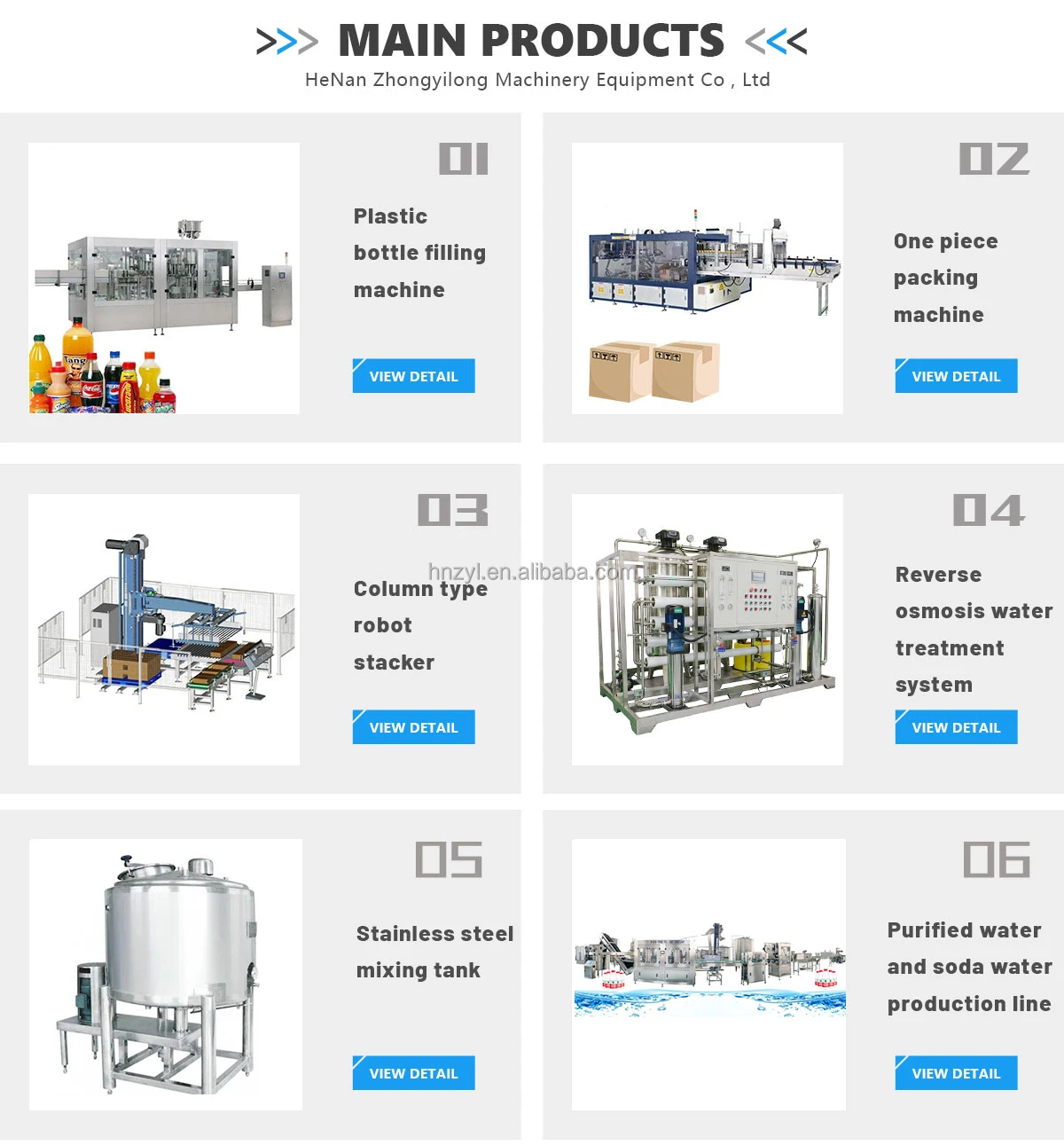

Related products

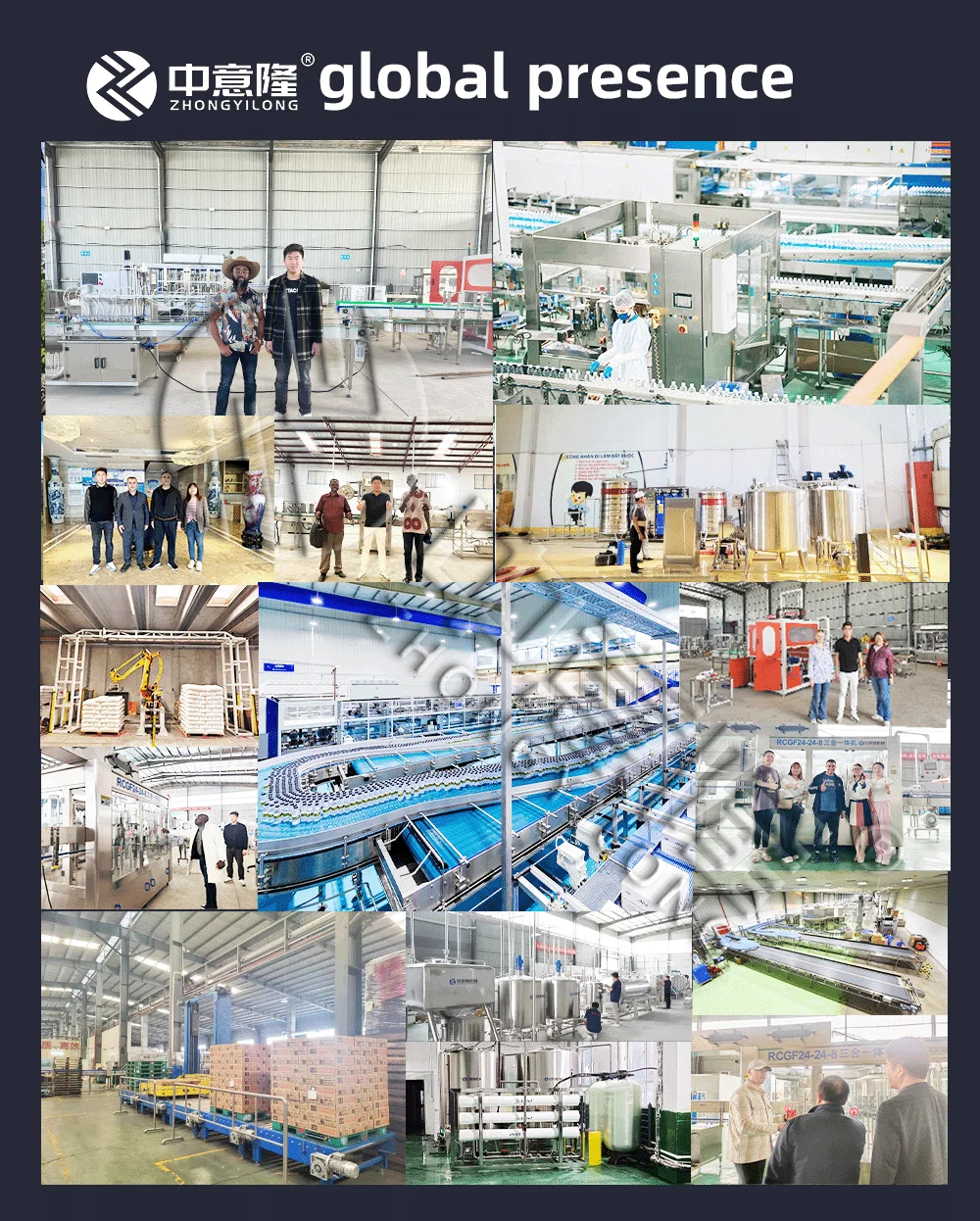

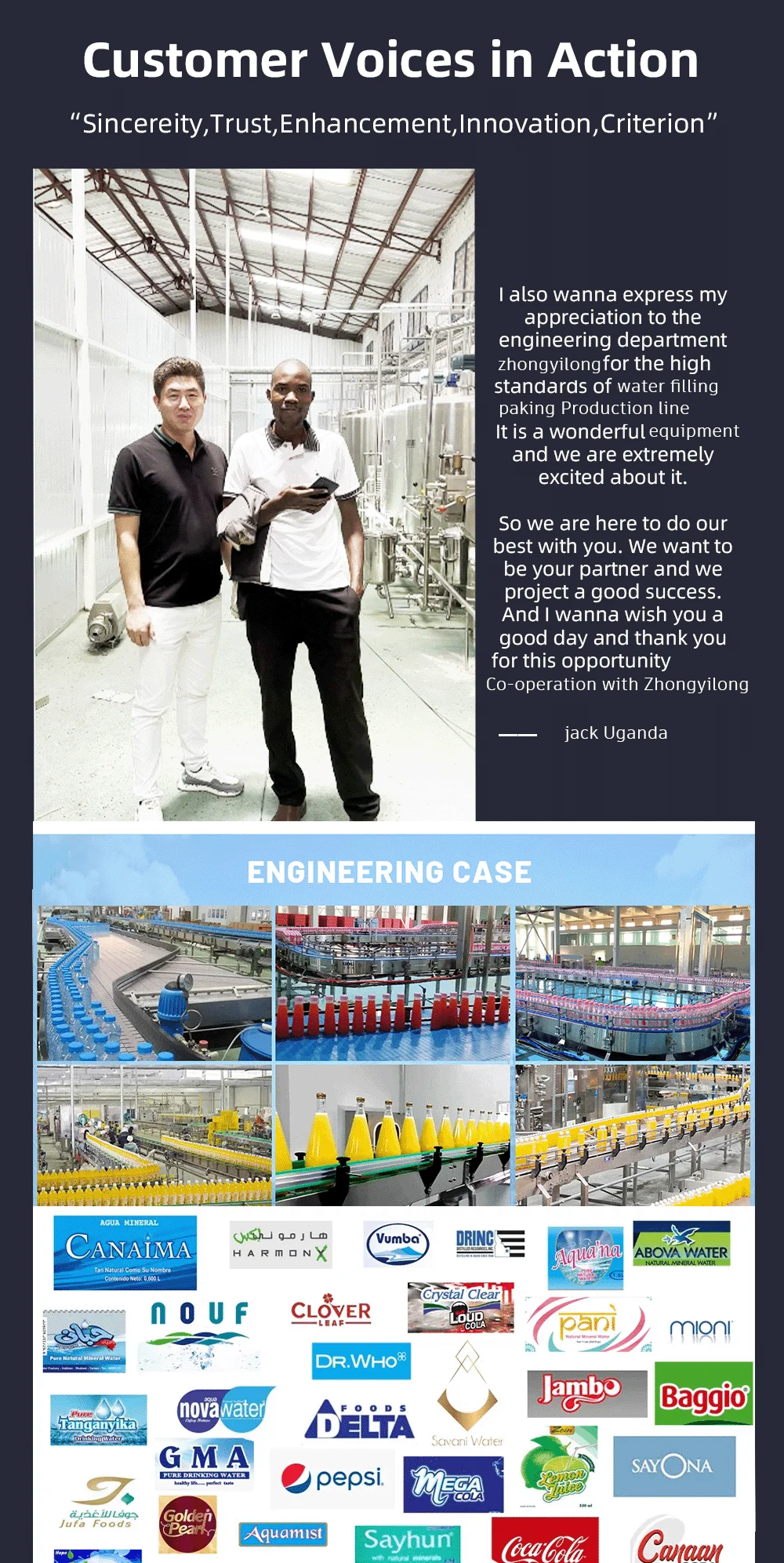

About us

Thanks for your inquiry on Alibaba. ZHONGYILONG Machienry co.,ltd. have been specializing in food&beverage processing line for many years and successfully set up 300 factories for demestic and international customers.

we are a high-tech manufacturing enterprise focusing on automatic packaging production equipment for food, beverage, fluids products. We can customize beverage production line process and formula according to customer's demand.

Our business scope covers dairy products, carbonated beverages, wine, beer, fermented beverages tomato paste, porridge, mixed juice drinks, vitamin functional drinks, pure water.cooking oil production lines, etc.

We provide one-stop service to help customers build food and beverage plants: process formula, plant guidance equipment selection, installation and commissioning, technical training, after-sales service.

We look forward to your inquiry and exchange cooperation.

To generally understand your requirement and facilitate our further communication, we'd like to know from you:

1.Will this be your own business or you are trading company?

2.what will be the scale of this project: home-scale ,commerical-scale or government procurement?

3.By which process: you already have process flowchart or we design for you?

4.what's the final products?

package and product specification detail

5.what's the estimated capacity?

input of raw material or output of final products, how much, by hour/daily or annual?

6.What's stage of this project are you in?

gathering information for future inspection

or want to finish this project in half or one year?

Please kindly understand that we will work very closely with you to offer an turn key solution.So firstly we should fully comprehend your situation in order to make out a reasonable project scheme with affordable cost.

Looking forward to your early response.

we are a high-tech manufacturing enterprise focusing on automatic packaging production equipment for food, beverage, fluids products. We can customize beverage production line process and formula according to customer's demand.

Our business scope covers dairy products, carbonated beverages, wine, beer, fermented beverages tomato paste, porridge, mixed juice drinks, vitamin functional drinks, pure water.cooking oil production lines, etc.

We provide one-stop service to help customers build food and beverage plants: process formula, plant guidance equipment selection, installation and commissioning, technical training, after-sales service.

We look forward to your inquiry and exchange cooperation.

To generally understand your requirement and facilitate our further communication, we'd like to know from you:

1.Will this be your own business or you are trading company?

2.what will be the scale of this project: home-scale ,commerical-scale or government procurement?

3.By which process: you already have process flowchart or we design for you?

4.what's the final products?

package and product specification detail

5.what's the estimated capacity?

input of raw material or output of final products, how much, by hour/daily or annual?

6.What's stage of this project are you in?

gathering information for future inspection

or want to finish this project in half or one year?

Please kindly understand that we will work very closely with you to offer an turn key solution.So firstly we should fully comprehend your situation in order to make out a reasonable project scheme with affordable cost.

Looking forward to your early response.

FAQ

The machinery market is vast and varied, with one product of interest being the filling machine. This device is a key player in industries such as food and beverage, cosmetics, and chemical production, where high-volume packaging is required. When investing in a filling machine, one of the pivotal factors to consider is the price.

However, understanding the price of a can-filling machine can be intricate, given the multitude of factors that influence it such as technology, capacity, and the associated features. zhongyilong machinery aims to provide a comprehensive guide to the pricing aspects of can-filling machines, directing potential buyers to make an informed decision.

However, understanding the price of a can-filling machine can be intricate, given the multitude of factors that influence it such as technology, capacity, and the associated features. zhongyilong machinery aims to provide a comprehensive guide to the pricing aspects of can-filling machines, directing potential buyers to make an informed decision.

Q: How much does a bottle-filling machine cost?

A: The cost of a bottle-filling machine can vary depending on the size, capacity, and level of automation.

Q: Can a bottle-filling machine handle carbonated beverages?

A: Yes, there are bottle-filling machines specifically designed to handle carbonated beverages. These machines are equipped with special filling heads and features to prevent excessive carbonation loss during the filling process.

Q: What is a fully automatic filling line?

A: A full automatic filling line refers to a complete production line that includes multiple machines and equipment for the automated filling, capping, and packaging of bottles or cans. It is designed to streamline the production process and increase efficiency.

Q: Where can I find bottle-filling machine manufacturers?

A: There are several bottle-filling machine manufacturers around the world. zhongyilong machinery is a reputable manufacturers. to ensure you choose areliable and high-quality machine. Contact our expert for help.

A: The cost of a bottle-filling machine can vary depending on the size, capacity, and level of automation.

Q: Can a bottle-filling machine handle carbonated beverages?

A: Yes, there are bottle-filling machines specifically designed to handle carbonated beverages. These machines are equipped with special filling heads and features to prevent excessive carbonation loss during the filling process.

Q: What is a fully automatic filling line?

A: A full automatic filling line refers to a complete production line that includes multiple machines and equipment for the automated filling, capping, and packaging of bottles or cans. It is designed to streamline the production process and increase efficiency.

Q: Where can I find bottle-filling machine manufacturers?

A: There are several bottle-filling machine manufacturers around the world. zhongyilong machinery is a reputable manufacturers. to ensure you choose areliable and high-quality machine. Contact our expert for help.

Похожие товары

Мини настольный автоматический горячий соус маленькая бутылка эфирное масло машина для наполнения и укупорки

УФ Клей Диспенсер

Винтовой конвейер из нержавеющей стали Полуавтоматический пластиковый гранулированный порошок питающий Лифт вакуумный винтовой питатель

97 483,88 ₽ - 101 821,32 ₽

Машина для розлива порошковых гранул, 100 г

493 383,35 ₽ - 498 805,14 ₽

Нержавеющая сталь питатель порошковый винт с частицами Автоматический подъемный конвейер для кормления пищевых продуктов сельскохозяйственный химический подъемник

97 483,88 ₽ - 101 821,32 ₽

Линия розлива воды Чистый бутылки минеральной воды производственной линии

12 тонн в час Автоматическая система очистки чистой воды для линии производства разлива воды

3 361 512,90 ₽ - 3 524 166,75 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

OrionStars онлайн-машина для рыбалки и свинга высокоприбыльная монетная игра США оптовая продажа агент с высокой прибылью Разыскивается

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $