SENFENG 5S по конкурентоспособной цене ручной лазерный сварщик Портативный Ручной Лазерный Сварочный Станок для очистки металла 3 в 1

- Категория: >>>

- Поставщик: Jinan Senfeng Laser Technology Co. Ltd.

Сохранить в закладки 1601275596510:

Описание и отзывы

Характеристики

Product Description

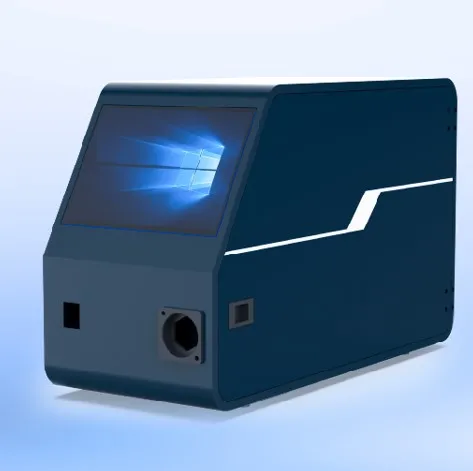

SENFENG Air-cooling Handheld Laser Welding Machine

Introduction

Laser welding refers to welding with the heat generated by focused laser beam hitting weldments. As the laser has optical features of refraction and focusing, laser welding is suitable for micro parts and parts with poor weldability. Senfeng portable handheld laser welding machine has the features of low heat input and small welding deformation and is not affected by electromagnetic fields.

Features

1.Low heat input, minimal deformation

2.Small size, air-cooling heat dissipation

3.Supports continuous long-term operation

4.Welding, cleaning, cutting, weld seam cleaning

2.Small size, air-cooling heat dissipation

3.Supports continuous long-term operation

4.Welding, cleaning, cutting, weld seam cleaning

Product parameter | ||||||

Model | SF3S | SF4S | SF5S | |||

Laser power regulation | 10%—100% | |||||

Wire feeding diameter | Standard 0.8-1.6mm | |||||

Weld splicing requirements | Self-fusion welding: ≤15% of the plate thickness and ≤0.5mm Filling wire welding: ≤1.2mm | |||||

Net weight | 40KG | 45KG | 50KG | |||

Wire feeder net weight | 13.2KG | |||||

Gross weight | 45KG | 50KG | 55KG | |||

Packing weight | 66KG | 71KG | 76KG | |||

Net size | 670X335X590mm | |||||

Wire feeder net size | 560X250X350mm | |||||

Packing size | 870X520X960mm | |||||

Welding thickness | 3m | ≤4mm | ≤5mm | |||

Total length of welding gun wire | 5m(wire feeding 5m) | 7m(wire feeding 5m) | 7m(wire feeding 5m) | |||

Welding gun weight | ≤0.7KG | |||||

Total power | 3kW | 4.5kW | 5.5kW | |||

Total power line length | 5m | |||||

Language | Chinese, English, Korean, Russian, Japanese, German, French, etc. | |||||

Voltage/frequency | Standard single-phase 220V 50/60HZ | |||||

LASER SOURCE | ||||||

Model | SF3S | SF4S | 5S | |||

Center wavelength(nm) | 1080±10 | |||||

Operating mode | Continuous/Modulated | |||||

Operating temperature | -10—40℃ | |||||

Power stability | ±3% | |||||

Output connector | QBH | |||||

Core diameter | 20 | |||||

Output fiber length(m) | 8 | |||||

Input power(V AC) | Single phase 220±10%V AC | |||||

Power adjustment range (%) | 10-100 | |||||

Beam quality(M²) | ≤1.1 | |||||

Cooling type | Air cooling | |||||

LASER HEAD

SYSTEM

AUTOMATIC WIRE FEEDER

LASER HEAD

AUTOMATIC WIRE FEEDER

1.Upgraded plastic welding gun head: integrated blue-black body for improved dust and leak resistance, lighter weight, and compact size. The key advantage is enhanced stability.

2.The protective lens and focusing lens now have a convenient drawer-style replacement, offering higher daily protection and simplified maintenance.

3.Temperature sensing alarm added to enhance welding gun lifespan.

4.Improved splash-proof structure with optimized scale tube to minimize protective lens wear.

5.Upgraded wire feeder with LCD display and high-torque DC motor for stable and smooth feeding.

6.Four-in-one control system allows flexible switching between welding, cleaning, weld seam cleaning, and cutting. Simple and flexible operation with multiple safety alarms.

2.The protective lens and focusing lens now have a convenient drawer-style replacement, offering higher daily protection and simplified maintenance.

3.Temperature sensing alarm added to enhance welding gun lifespan.

4.Improved splash-proof structure with optimized scale tube to minimize protective lens wear.

5.Upgraded wire feeder with LCD display and high-torque DC motor for stable and smooth feeding.

6.Four-in-one control system allows flexible switching between welding, cleaning, weld seam cleaning, and cutting. Simple and flexible operation with multiple safety alarms.

SYSTEM

1.The new-generation welding system developed by Senfeng features a user-friendly interface with clear visuals and straightforward operation, integrating welding, cleaning, weld cleaning, and cutting functions into one device.

2.The large control knob for adjusting power and spot width is designed for ease of use, providing a more intuitive, visible, and efficient operation.

3.The large knob adjustment and touchscreen interface allow for quick switching; adjusting the knob immediately brings up the dial interface on the main page, while touching the screen swiftly transitions back to the main page.

2.The large control knob for adjusting power and spot width is designed for ease of use, providing a more intuitive, visible, and efficient operation.

3.The large knob adjustment and touchscreen interface allow for quick switching; adjusting the knob immediately brings up the dial interface on the main page, while touching the screen swiftly transitions back to the main page.

AUTOMATIC WIRE FEEDER

1.Standard high-power four-wheel dual-drive wire feeder. The wire feeding speed is adjustable from 25-600cm/min. It also supports continuous and pulse wire feeding mode, making wire feeding stable and smooth.

2.The wire feeder comes standard with a 1.6mm wire feed tube. And there is an aluminum wire feeding solution with a U-shaped wheel and a graphite wire feed tube (optional).

3.The wire feeder comes standard with an LCD display, which can intelligently control speed, wire feeding and withdrawal.

2.The wire feeder comes standard with a 1.6mm wire feed tube. And there is an aluminum wire feeding solution with a U-shaped wheel and a graphite wire feed tube (optional).

3.The wire feeder comes standard with an LCD display, which can intelligently control speed, wire feeding and withdrawal.

Recommend Products

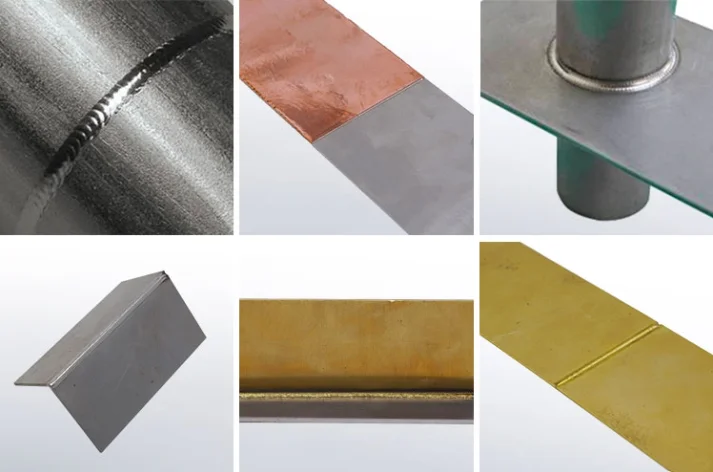

Welding Samples

Application Industry

Company Profile

Our Advantages

We attend many exhibitions every year. Our customers from more than 180 countries.Thank you very much for all customers trusting us . If you have any questions, please feel free to contact us!

Product packaging

FAQ

1. Why choose Senfeng?

Senfeng, as a leading integrated manufacturer of fiber laser machines for cutting, welding, cleaning, cladding as well as electric bending machine, provides various solutions in the field of fabricating machinery with cutting-edge technology.

We also establish cooperative relations with as many as 160 countries worldwide, with training and services provided abroad, to provide the best after-sales service.

Senfeng, as a leading integrated manufacturer of fiber laser machines for cutting, welding, cleaning, cladding as well as electric bending machine, provides various solutions in the field of fabricating machinery with cutting-edge technology.

We also establish cooperative relations with as many as 160 countries worldwide, with training and services provided abroad, to provide the best after-sales service.

2. Where is the sales service center?

Senfeng has established 2 subsidiaries in the United States, and Germany and 5 service centers in India, Pakistan, Serbia, Vietnam and Jordan.

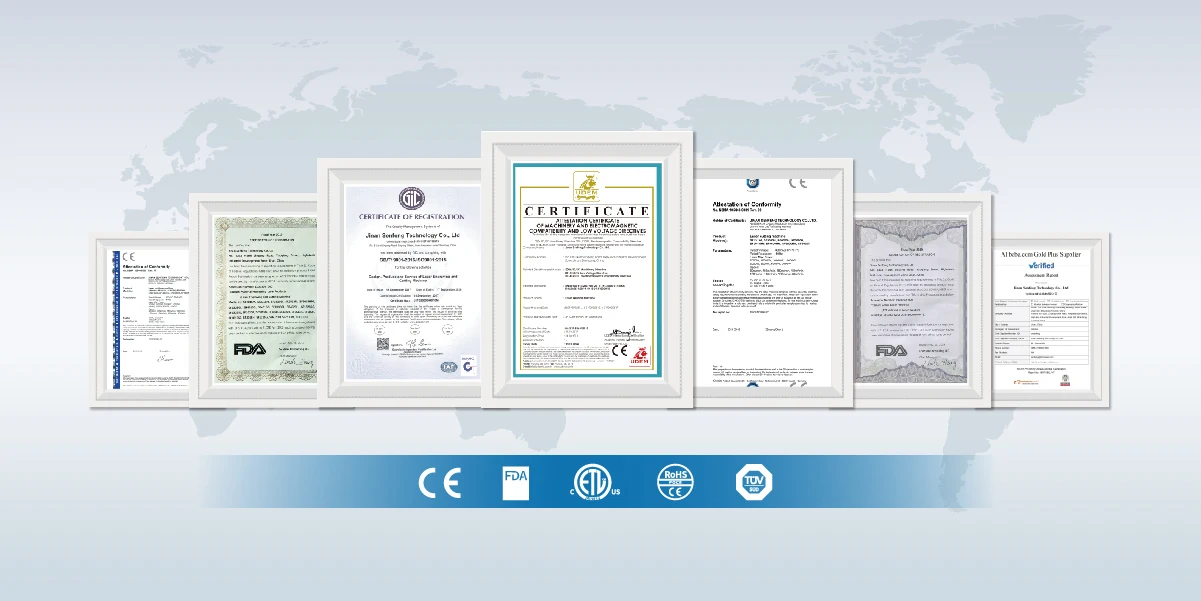

3. What certification does the machine have?

Senfeng has passed CE from TÜV, ROHS, ETL certificates, which is in line with European and American standards.

4. How to choose the right machine for me?

Very easy to choose. Tell us what you want to do with a fiber laser, and we'll match you with the perfect solution and advice.

5. What materials can our machine cut?

A fiber laser cutting machine is extremely useful in cutting sheet metal including carbon steel, stainless steel, copper, brass, aluminum, and titanium.

6. How long is the warranty time?

The whole machine is guaranteed for 2 years.

7. Payment terms?

Alibaba trade assurance/TT/West Union/Paypal/LC/Cash and so on.

8. Machine delivery time?

The delivery time of equipment is usually more than 30 days.

9. It's not convenient for me to go to China, but I want to see the condition of the machines in the factory. What should I do?

If it’s not convenient to come to China, our sales manager can take you to know the factory by online video conference.

10. What does the customer need to prepare before dispatching technicians?

It is necessary for the customer to confirm in advance that the machine is placed in the proper position, and to prepare the

factory power supply, distilled water, auxiliary gas and the metal sheets to be cut and debugged. Additionally, the client needs to book hotels for our technicians.

Senfeng has established 2 subsidiaries in the United States, and Germany and 5 service centers in India, Pakistan, Serbia, Vietnam and Jordan.

3. What certification does the machine have?

Senfeng has passed CE from TÜV, ROHS, ETL certificates, which is in line with European and American standards.

4. How to choose the right machine for me?

Very easy to choose. Tell us what you want to do with a fiber laser, and we'll match you with the perfect solution and advice.

5. What materials can our machine cut?

A fiber laser cutting machine is extremely useful in cutting sheet metal including carbon steel, stainless steel, copper, brass, aluminum, and titanium.

6. How long is the warranty time?

The whole machine is guaranteed for 2 years.

7. Payment terms?

Alibaba trade assurance/TT/West Union/Paypal/LC/Cash and so on.

8. Machine delivery time?

The delivery time of equipment is usually more than 30 days.

9. It's not convenient for me to go to China, but I want to see the condition of the machines in the factory. What should I do?

If it’s not convenient to come to China, our sales manager can take you to know the factory by online video conference.

10. What does the customer need to prepare before dispatching technicians?

It is necessary for the customer to confirm in advance that the machine is placed in the proper position, and to prepare the

factory power supply, distilled water, auxiliary gas and the metal sheets to be cut and debugged. Additionally, the client needs to book hotels for our technicians.

Похожие товары

Высококачественный лазерный сварочный аппарат SENFENG S портативный ручной хромированный с воздушным охлаждением 3 в 1

Профессиональный лазерный сварщик SENFENG для металла портативный ручной 800 Вт 1200 1500 аппарат сварки алюминия

HS4S/5S 1200 Вт/1000 Вт 3 в 1 портативная ручная волоконно-лазерная сварочная машина для очистки металла с воздушным охлаждением

SENFENG S Лидер продаж 3 в 1 портативный ручной лазерный сварочный аппарат с воздушным охлаждением

SENFENG S индивидуальный портативный аппарат для воздушного охлаждения недорогой простой в эксплуатации лазерный сварочный 3 1 металла

SENFENG S Новая модель металлическая лазерная сварочная машина с воздушным охлаждением портативный никель Бестселлер 1000 Вт 1500 3 в 1 лазерный сварочный аппарат

Высококачественный 5S лазерный сварочный аппарат SENFENG портативный ручной хромированный с воздушным охлаждением 3 в 1

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $