Ферма корм для кур гранулятор животных

15 378,89 ₽

Сохранить в закладки 1601277777289:

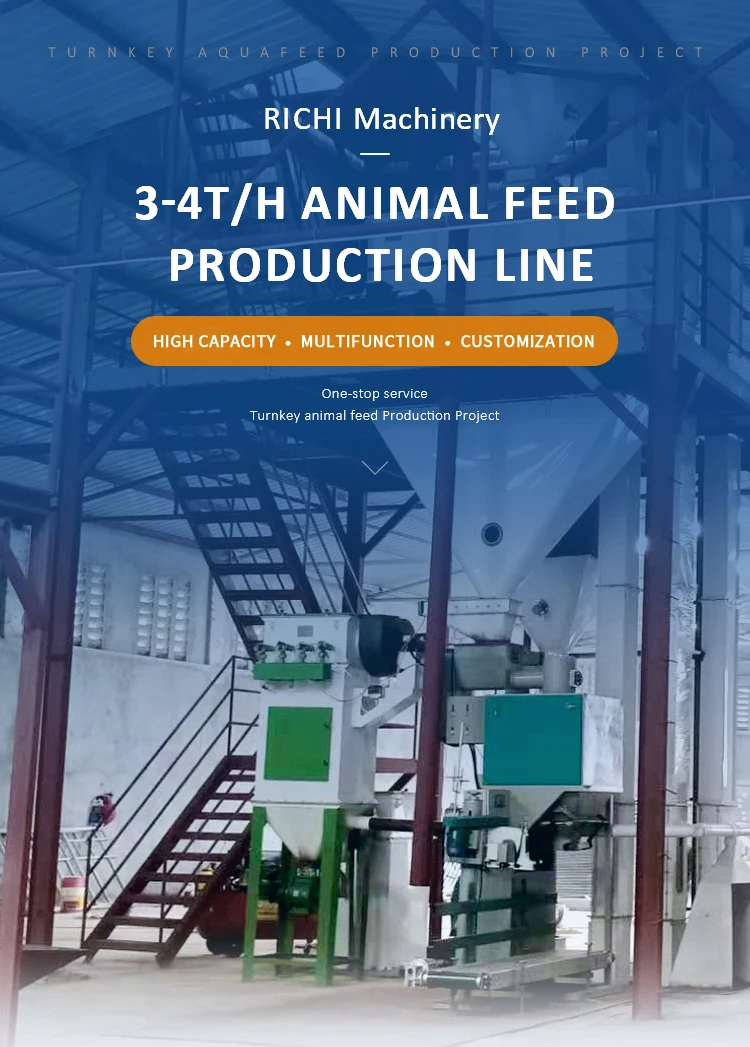

Capacity | 3~4 Ton Per Hour |

Power(Kw) | 70~215 Kw Customized |

Area & High | Customized Designs Based on Actual Area and Height Restrictions |

Supported Feed Types | Multifunctional, Livestock Feed, Poultry Feed, Sinking Fish and Shrimp Feed etc |

Supported Feed Size | 2~12 mm |

Новинки товаров от производителей по оптовым ценам