Детали для строительной техники оборудование инспекции троса

- Категория: >>>

- Поставщик: Weite Technologies Co. Ltd.

Сохранить в закладки 1601279101930:

Описание и отзывы

Характеристики

For a long time, the maintenance and management of steel wire ropes for lifting equipment has been a difficult point in the equipment management of various enterprises. Accidents caused by broken wire ropes are common, and each accident is accompanied by serious consequences such as property loss and casualties.

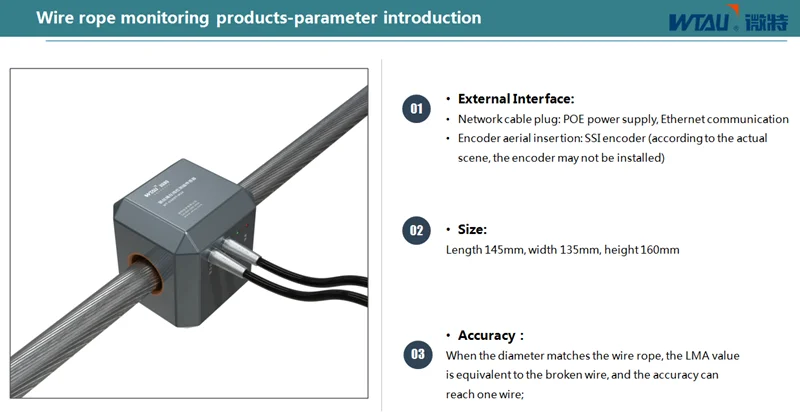

| Model type | WRNDT |

| advantages | four advantages |

| three type of equipments | online way; portable;integrated |

| applying | for crane |

| Starting wind velocity | < 0.2 m/s |

| Action Error | ≤3% |

Four advantages

The non-destructive testing system for wire ropes of Weite‘s lifting equipment has unique advantages with its unique testing method and brand-new industrial design:

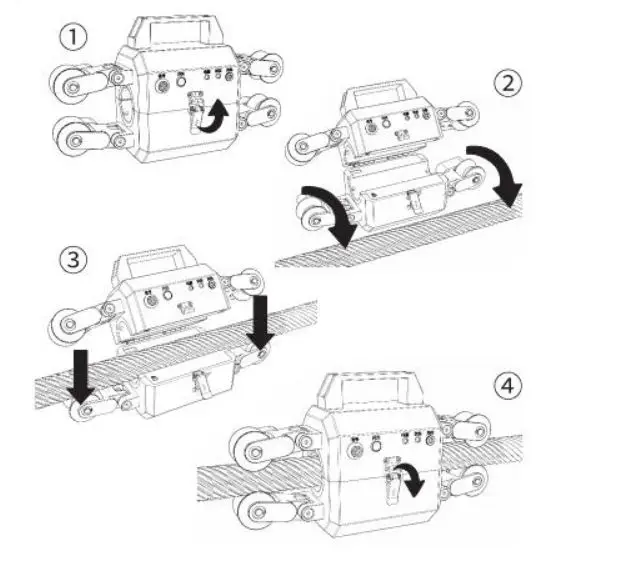

Three types of equipment

For different application scenarios, Weite has launched three types of equipment: online, integrated, and portable, which are suitable for various industries such as ports, ships, roads and bridges, cableways, steel mills, hoisting, construction sites, and petroleum.

The Weite's wire rope non-destructive testing system provides customers with a scientific and effective wire rope maintenance solution. It can not only be used independently, but also provide important wire rope health data and analysis reports to the equipment intelligent maintenance platform, which is an indispensable part of future smart management.

China Weite Technologies Co., Ltd.

Weite Technologies Co. Ltd(factory) was born in 2002 year-Top 3 brand in China. We help to protect cranes and lifting equipment under safety working condition with customized WTAU Load Moment Indicator(LMI), Safe Monitoring System, Anti Collision System, Marine CCTV Camera System, overload limiter, length angle sensor, load cell sensor, Anemometers, A2B anti two block device etc.

Weite Technologies Co.,Ltd

Founded in 2002, it is national hi-tech enterprise located in Yichang, China. It has been focusing on R&D and OEM manufacturing of lifting safety protection devices such as Load Moment Indicator, Safe monitoring systems, overload limiter, Load cell, Anemometers etc.We continuously concentrate on ensuring lifting equipments run safely as long-term pursuing goal.

"The trusted Safety Partner for Global Top 100 Crane Owning Companies like Tat Hong, Asiagroup, Big Crane and Fortune 500 corps" . Nowadays, WTAU products are widely used in marine industry,electrical, chemical, steel, metallurgy, construction, ports and other industries, and have been wide spreaded to over 70 countries and regions.

Похожие товары

Для Epiroc-BS/Atlas Copco-BS/Sandvil-BS/поддон для дрели/3128078437

Epiroc-BS/Atlas Copco-BS/Sandvil-BS/Overc Valve/8231120686

Epiroc-BS/Atlas Copco-BS/Sandvil-BS/Встраиваемая переработка ступицы/2657570814

XE210CU XE210.13.2.A запасные части для экскаватора 800305567 охладителя топлива

Новый двигатель с главным подшипником двигателя C-10 C-12 C11 C13 3508B экскаватор 345B 345BL 211-0588 211-0587

Epiroc-BS/Atlas Copco-BS/Sandvil-BS/Направляющий Блок/2310058931

Высокое качество 4bg1 двигатель в сборе

Новые поступления

Новинки товаров от производителей по оптовым ценам