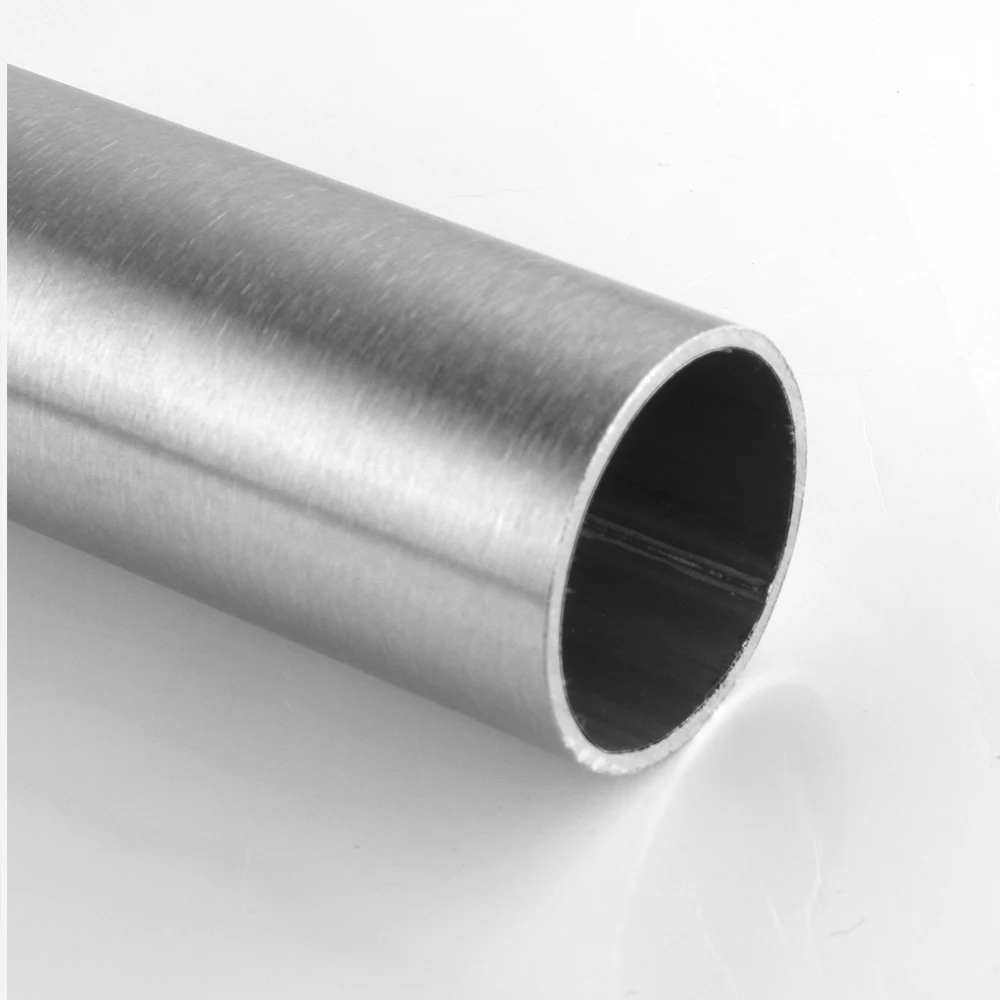

304 316 сварные трубы из нержавеющей стали Inox AISI

- Категория: >>>

- Поставщик: Foshan Vinmay Stainless Steel Co. Ltd.

Сохранить в закладки 1601279298075:

Описание и отзывы

Характеристики

Product Information

Product Name | Stainless Steel Welded Pipe | ||||||

Model Number | VM 1001 | ||||||

Material | 201/ 304 /304L/316L/409/430 | ||||||

Certificate | ISO / AEO/ MTC | ||||||

MOQ | 1 Ton | ||||||

Size | 6mm-219mm | ||||||

Surface | MF,180 Grit, 320 Grit, 400 Grit, 600 Grit | ||||||

Thickness | 0.6mm-5.0mm | ||||||

Delivery Time | 30 days for a container quantity | ||||||

Payment Terms | T/T, LC, Cash, etc. Normally 30% by T/T in advance, balance to be paid before shipment. | ||||||

Packing | Each tube will be packed in plastic bag, then several tubes will be packed by hollow plate or weaving bags. | ||||||

Size List

Application

Product Advantage

Vinmay Tubing Born to Last and Sparkle (Taiwan quality)

Production Processes

Product packaging

One Stop Service for Stainless Steel Railing Fitings ,

Profile and Sheets

Stainless Steel Profile and Sheets

Handrail Fittings

Company Profile

About Us

Foshan Vinmay Stainless Steel Co.,ltd is a ISO 9001 2015 certificated company mainly specialized in stainless steel welded tube for ornamental and mechanical structure purposes, stainless steel welded tube for heat exchanger, sanitary stainless steel tube and handrail fittings. Currently we export more than 25000 tons of stainless steel pipe every year of which the export volume of the decorative stainless steel pipe is leading in China.

Professional Team and Service

Exhibition

Contact Us

FAQ

1. What is your location?

We are located in Sanshui District, Foshan City which is a famous stainless steel production base.

2.What's the annual output?

Vinmay produce more than 25000 tons stainless steel tubes in a year.

3. What is your welding method?

All of our tubes are welded by tig welding methods. Our tubes can get fully welding and smoonth inner welding, without blisters,

leak welding or black line. All of our tube are good for tube bending.

4. How do you control the quality during the polishing process?

1)As for the mirror polish square/rectangular tube , we will polish it as least four times)

2)During the polishing processing, we set a special sanding wheel to polish the welding part.

3)To avoid scratches,after polishing,the tubes will be lay out on a steel crate then we could lift the whole steel crate instead

of the tube.

4)On the other hand, we use the gunny bags to protect the tube's surface when the tube laying-out.

5. How do you inspect the tubes?

The Quality inspectors inspect the tubes during each production processes from raw material,tube welding,polishing,packaging.

1) Before the production of each machine, we will have the first checked and record the data.

2). During the production, our inspector and engineer have been carefully moniting and we record the data every two hours.

We are located in Sanshui District, Foshan City which is a famous stainless steel production base.

2.What's the annual output?

Vinmay produce more than 25000 tons stainless steel tubes in a year.

3. What is your welding method?

All of our tubes are welded by tig welding methods. Our tubes can get fully welding and smoonth inner welding, without blisters,

leak welding or black line. All of our tube are good for tube bending.

4. How do you control the quality during the polishing process?

1)As for the mirror polish square/rectangular tube , we will polish it as least four times)

2)During the polishing processing, we set a special sanding wheel to polish the welding part.

3)To avoid scratches,after polishing,the tubes will be lay out on a steel crate then we could lift the whole steel crate instead

of the tube.

4)On the other hand, we use the gunny bags to protect the tube's surface when the tube laying-out.

5. How do you inspect the tubes?

The Quality inspectors inspect the tubes during each production processes from raw material,tube welding,polishing,packaging.

1) Before the production of each machine, we will have the first checked and record the data.

2). During the production, our inspector and engineer have been carefully moniting and we record the data every two hours.

Похожие товары

Один контейнер 15-30 дней доставки 0 4 мм толщина нержавеющей стали Занавеску трубки

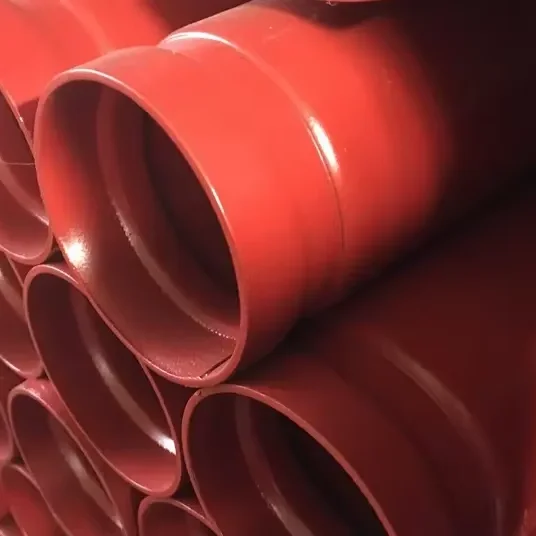

Система защиты противопожарных труб ASTM A795 для пожаротушения

43 973,16 ₽ - 49 483,58 ₽

Лучшие продажи качество 201 202 301 304 304L 321 316 316L труба из нержавеющей стали 8 мм 0 5ct

154 181,56 ₽ - 231 327,44 ₽

316 25 мм 20 малогабаритная капиллярная трубка из нержавеющей стали тонкостенная труба бесшовная

192 864,70 ₽ - 275 521,00 ₽

Основная капиллярная труба из нержавеющей стали/труба тонкая Тяжелая стенка полая секция бесшовные трубы стали малого диаметра

181 843,86 ₽ - 209 395,96 ₽

Rectangular Square Round Hollow Section 302 303 409l 2205 304l C276 Stainless Steel Pipe Tube Aisi 201 304 316 430 Grade

143,28 ₽ - 198,38 ₽

Хорошая цена горячекатаная труба из нержавеющей стали A312 1 дюйм 27 дюймов ASTM A213 316 ч Lmod 317 347 140 мм Трубная

3 306,26 ₽ - 4 408,34 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $

Съемная пластиковая ручка штукатурка строительный инструмент для отделки бетона с помощью меток

SHIDU U30 двойной беспроводной Перезаряжаемый Профессиональный UHF микрофон караоке с

39,90-57,40 $

1688 закупка Taobao дропшиппинг агент по покупке онлайн-покупки Китай в Испания Румыния Литва от двери до ddp servic

1 $

OEM стираемая зеленая пластиковая клипса с держателем для ручки магнитная футбольная тренировочная

2-2,80 $