Китайский производитель порошковый воздушный классификатор мельница с циклоном для керамики

- Категория: >>>

- Поставщик: Weifang Guote Mining Equipment Co. Ltd.Weifang Ltd.

Сохранить в закладки 1601279434354:

Описание и отзывы

Характеристики

Air classifier

Products Description

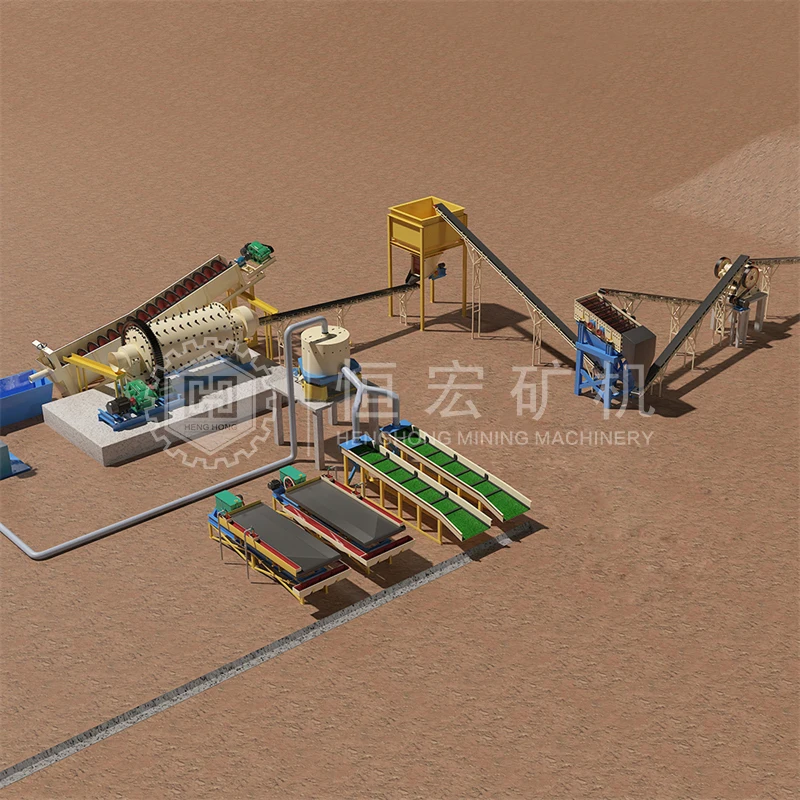

The classifier system consists of air classifier, cyclone separator, dust collector, induced draft fan, and electric control cabinet.

The classifying device is composed of pneumatic classifier, cyclone, collector, induced draft fan, control cabinet and so on.

Equipped with second air inlet and vertical impeller rotor, the materials are fed in visa the bottom roller under the force generated from the induced draft fan and then mixed with first input air to disperse particle and then brought to classifying zone. Owing to the high rotary speed of classifying rotor, the particles are under the centrifugal force produced by the

classifying rotor and centripetal force generated from induced draft fan. When the centrifugal force is stronger than the centripetal force, the coarse particles fall down along inside roller. The second air is induced to sieve the coarse material and separate the fine powder that stick on or mixed with the coarse. After the coarse material is discharged from classifier, the over-milled powder are collected by the cyclone and pulse collector.

Equipped with second air inlet and vertical impeller rotor, the materials are fed in visa the bottom roller under the force generated from the induced draft fan and then mixed with first input air to disperse particle and then brought to classifying zone. Owing to the high rotary speed of classifying rotor, the particles are under the centrifugal force produced by the

classifying rotor and centripetal force generated from induced draft fan. When the centrifugal force is stronger than the centripetal force, the coarse particles fall down along inside roller. The second air is induced to sieve the coarse material and separate the fine powder that stick on or mixed with the coarse. After the coarse material is discharged from classifier, the over-milled powder are collected by the cyclone and pulse collector.

Details Images

1.Silo 2.operating platform 3.air classifier 4. cyclone collector 5. dust collector 6.induced draft fan 7.electric control cabinet

Working Principle

The materials are fed in visa the bottom roller under the force generated from the induced draft fan and then mixed with first input air to disperse particle and then brought to classifying zone. Owing to the high rotary speed of classifying rotor, the particles are under the centrifugal force produced by the classifying rotor and centripetal force generated from induced draft fan. When the centrifugal force is stronger than the centripetal force, the coarse particles fall down along inside roller. The second air is induced to sieve the coarse material and separate the fine powder that stick on or mixed with the coarse. After the coarse material is discharged from classifier, the over-milled powder are collected by the cyclone and pulse collector

Product Paramenters

Outstanding Advantages

1.With special design for classifying structure and its high classifying precision, it can block big granular strictly.

2.To get the required product, you can adjust the rotary speed of classifying wheel and air inlet volume.

3.Single vertical rotor with low speed, steady flow field, high efficiency and robust performance.

4.With multi-series structure, it can get products with different size to meet requirement

2.To get the required product, you can adjust the rotary speed of classifying wheel and air inlet volume.

3.Single vertical rotor with low speed, steady flow field, high efficiency and robust performance.

4.With multi-series structure, it can get products with different size to meet requirement

Company Profile

Basic Company Introduction

Weifang guote mining equipment Co.,Ltd. is located in Qingzhou Economic Development Zone, Weifang City, Shandong Province. It covers an area of 40000 square meters. It is a high-tech enterprise in Shandong Province. The company has passed ISO9001 quality system certification, environmental system certification, safety management system certification, EU CE certification and more than ten useful national invention patents.

About GUOTE

Guote Mining equipment has long been committed to the production of quartz sand, silicon powder, feldspar and oil field fracturing

sand special equipment, and provide non-metallic ore production line experiment, design, consulting and the whole line equipment supply;such as:quartz sand making processing line equipment;glass sand making processing line equipment ;quartz powder making machine;sand washing system;drum dryer machine;dewatering screen equipment;vibration screen;scrubber attrition machine;magnetic separator machine...etc...

sand special equipment, and provide non-metallic ore production line experiment, design, consulting and the whole line equipment supply;such as:quartz sand making processing line equipment;glass sand making processing line equipment ;quartz powder making machine;sand washing system;drum dryer machine;dewatering screen equipment;vibration screen;scrubber attrition machine;magnetic separator machine...etc...

Certifications

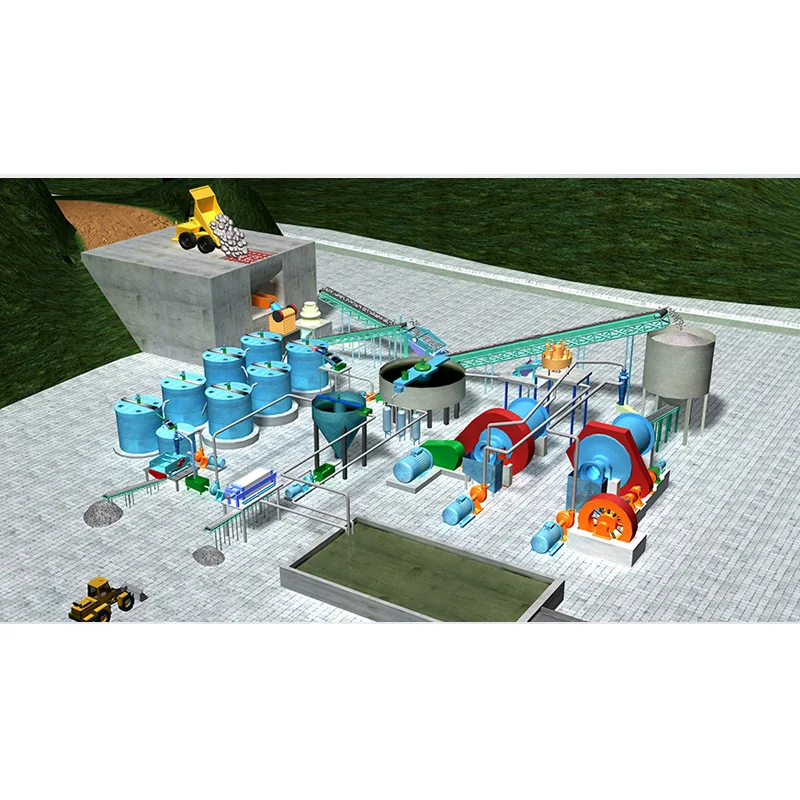

Customer Photos

About customers:

Our products are very popular at home and abroad, exported to Japan, South Korea,Thailand, Pakistan, Bangladesh, South Africa, India, Indonesia, Brazil, Vietnam, Malaysia and more than a dozen other countries and regions.

Contact Information

Weifang Guote Mining Equipment Co., Ltd.

Contact: Yolanda (Sales manager)

Mobile :+86 156 8429 0980 whatsapp/wechat)

Add: Dongjing Road East, Industrial Zone,Qingzhou City, Weifang,Shandong Province, P.R.China

E-mail: yolanda@sdguote.com

Alibaba website: //sdguote.en.alibaba.com/

Webstie: www.guotegroup.com

If you have any questions, pls don't hesitate to contact me. We will reply you ASAP.

Contact: Yolanda (Sales manager)

Mobile :+86 156 8429 0980 whatsapp/wechat)

Add: Dongjing Road East, Industrial Zone,Qingzhou City, Weifang,Shandong Province, P.R.China

E-mail: yolanda@sdguote.com

Alibaba website: //sdguote.en.alibaba.com/

Webstie: www.guotegroup.com

If you have any questions, pls don't hesitate to contact me. We will reply you ASAP.

Похожие товары

Энергосберегающая установка для обогащения хрома оборудование

10 000,00 $

Подвесной магнитный металлический сепаратор для конвейерной ленты бренд CHNMAG

Магнитный сепаратор для повышения белизны полевого шпата

Минеральное оборудование подвесной электромагнитный сепаратор RCDD магнитный для ленточного конвейера

1 200,00-3 000,00 $

Купить минеральный винтовой спиральный классификатор

1 000,00-12 500,00 $

Haiwang cyclone FX модели гидравлический гидроциклонный десандер Циклон Золотой концентратор

1 000,00-1 200,00 $

Фабрика по переработке золота обогащение золотой руды 10 т/ч 50 100 200 машина для обработки Аллювиального

18 000,00-20 000,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $