COLO-Mini01 цилиндр для флюидизирующего покрытия небольшой бункер порошкового

6 030,67 ₽ - 7 127,15 ₽

Сохранить в закладки 1601279699746:

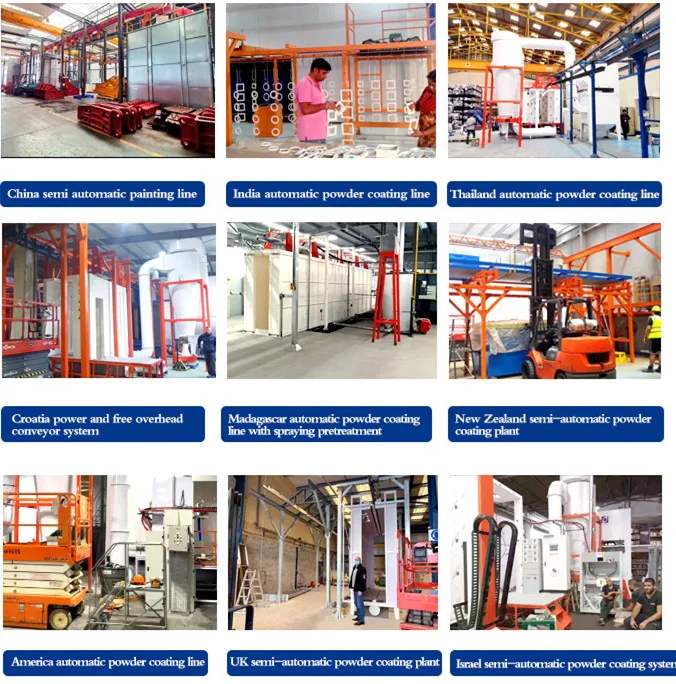

Process Item | Classify | Factor |

Pre-treatment | Spraying type, Submarine type, Dip tank Type, Shot/Sand blasting | Save manpower, improve the powder coating performance |

Drying after spraying | 10 minutes in drying oven | |

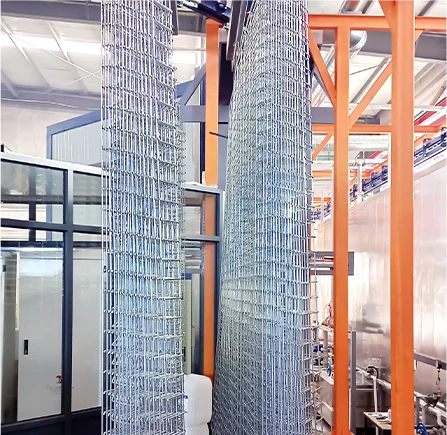

Powder coating | Cyclone powder coating booth/Filter recovery powder coating booth/Manual powder coating machine | Fast color change(15min), high powder recovery rate(99.2%), no dust spill out, easy to clean, good spraying effect. |

Curing | Bridge type curing oven, Tunnel type curing oven, Box type oven. | Temperature difference less than 3 degree, save energy, lower operating cost, high safety. |

Conveyor system | Manual conveyor, Automatic conveyor, Power and free conveyor. | Easy to assemble, flexible, lower maintenance. |

Новинки товаров от производителей по оптовым ценам