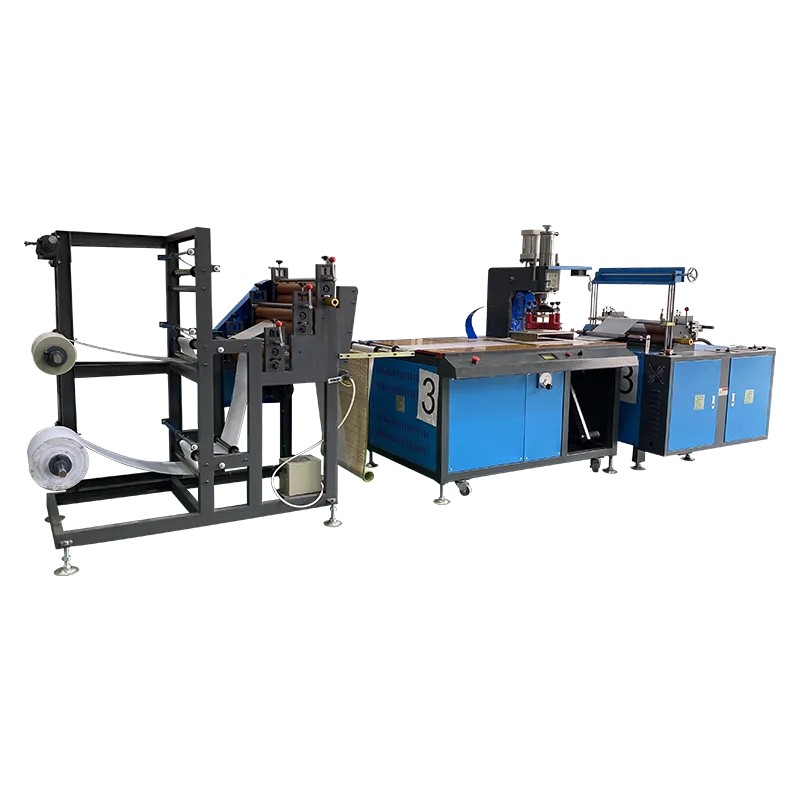

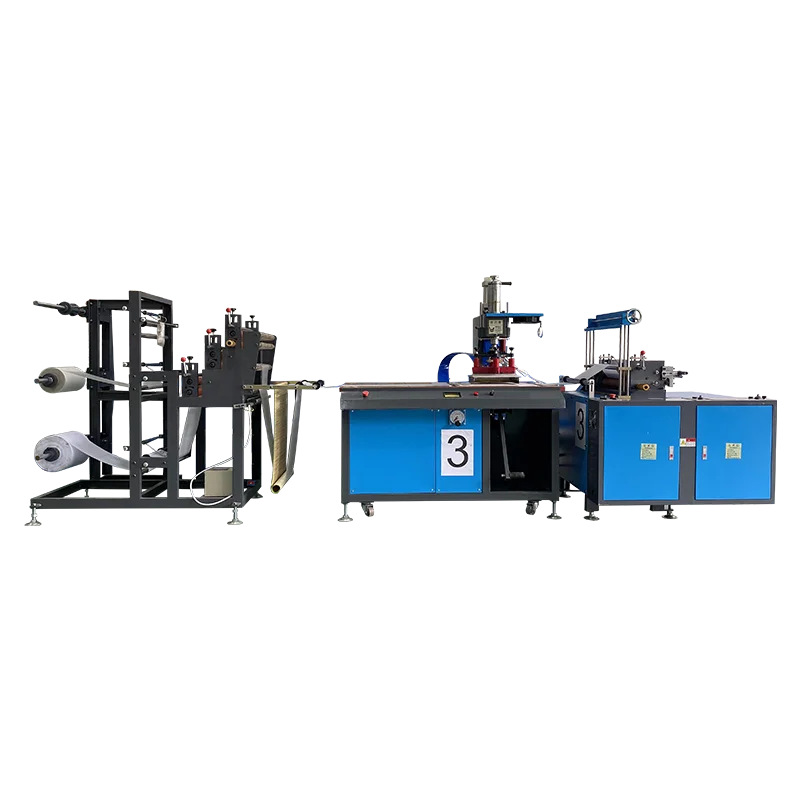

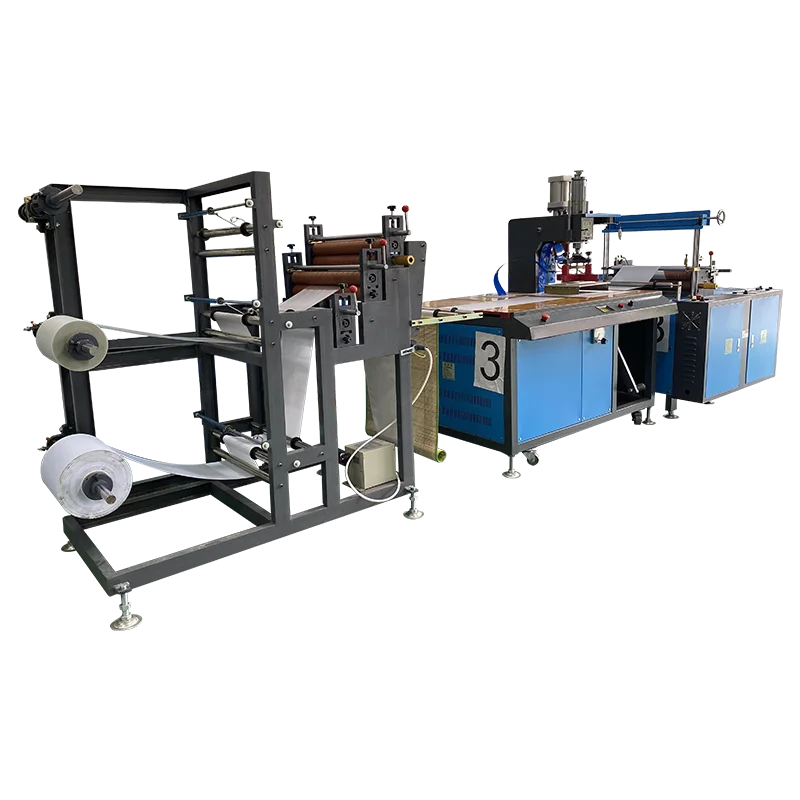

Автоматическая ПВХ пластиковая упаковка мешок делая машину

- Категория: >>>

- Поставщик: Wuxi Guochiqiang Packaging Machinery Co. ltdWuxi ltd

Сохранить в закладки 1601279710097:

Описание и отзывы

Характеристики

1. PLC and touch screen control system, with precise, easily, simplify operate.

2. Full automatic system from A to Z.

3. Feeding material and, welding bag and cutting automatically.

4. One cycle time about 5-6seconds, machine capacity about 800pcs of bags and tube per hour.

5. Machine size: L5200mm*W5000mm*H2000mm

6. Servo motor drive system with precise position running.

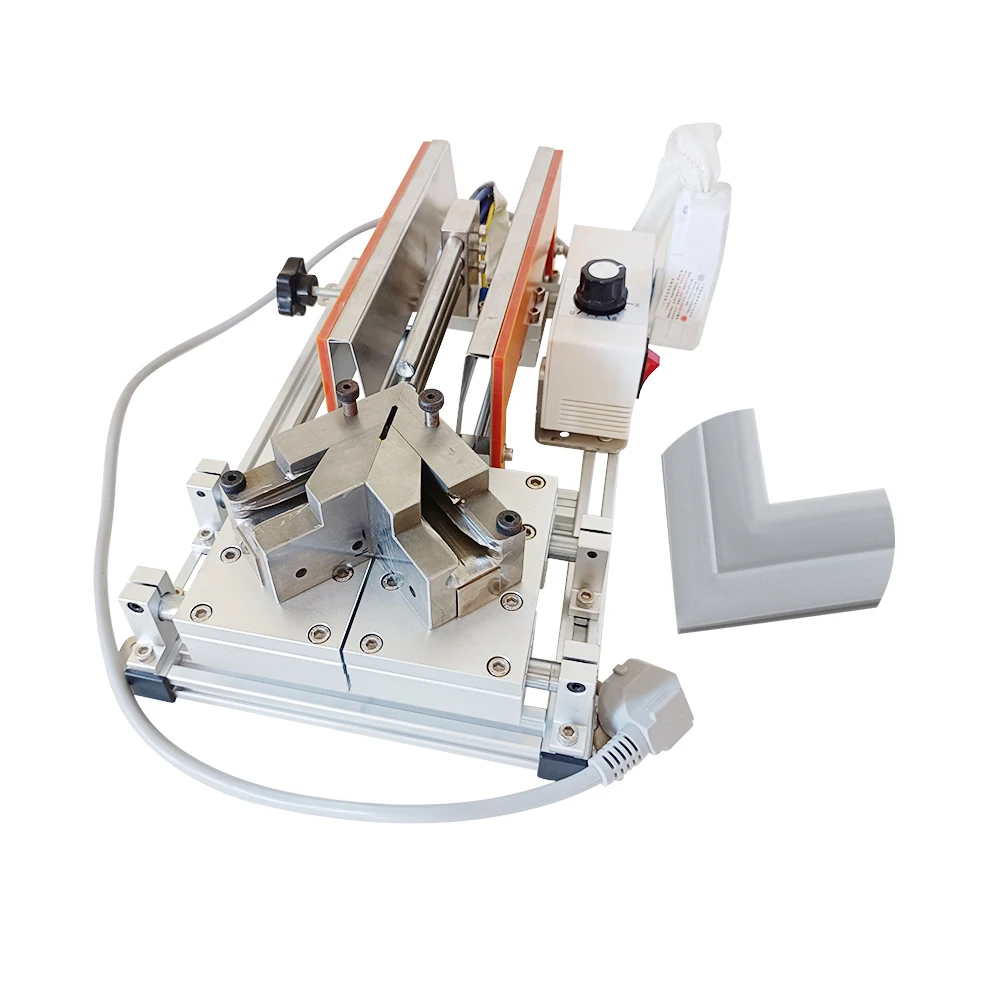

Model No | GCQ-W12KW | GCQ-W15KW | GCQ-W25KW |

Voltage | AC220/380/400/415/440V 50/60HZ(Customized) | ||

Output Power | 12KW | 15KW | 25KW |

Input Power | 15KVA | 18KVA | 28KVA |

HF Frequency | 27.12MHZ ±0.6% | ||

Oscillation Tube | 8T85RB | 8T85RB | 8T85RB |

Anti-spark Tube | NL-5557 | NL-5557 | NL-5557 |

Gap of Electrode | 200mm | 200mm | 200mm |

Size of upper electrode | 400×800mm | 400×1000mm | 400×1200mm |

Machine Size | 6500×2100×1900 | 6500×2100×1900 | 6500×2100×1900 |

Machine Weight | 1500KG | 1500KG | 1500KG |

Sample workshop

We are there for you right from the start. Even during the quotation phase we will create preparatory samples in our company-owned testing department and will then supply you with a welding specimen as a sample to present to your customer or to evaluate the welding results. For this, we have a wide variety of sample-production tools at our disposal. You will now be able to judge for yourself which is the best welding process. And you can even do so before making an actual investment.

New development work

Assembly

By setting up and commissioning the machinery we deliver, you can be sure that it will be professionally assembled and that operation will be monitored during the important start-up phase.

This service includes both setting up new machinery and converting welding machinery. You can even avail of this service where machines were manufactured by third party suppliers.

If you are interested in this service, we will be happy to hear from you.

Service centre

Our qualified service team can care for your HF machinery anywhere in the world. Thanks to our continuous training and further training programme, we have highly qualified professionals working in the field of HF technology and are making a further investment in the future. In addition to providing services for our own machinery, we also provide services for various other third party makes – just ask us!

Conversion and refurbishment

Modifying existing machinery in line with changes in production processes by converting or extending it is part of the daily routine for our service team. Whether the machinery in question is a Schirmacher system or equipment supplied by third parties is unimportant.

Refurbishing through us gives your machine a second life and increases reliability. Profitability of your investment will remain

Похожие товары

Изготовленный на китайских фабриках 5 кВт ткань ПВХ высокочастотный индукционный сварочный аппарат для пляжного кресла

Машина для производства мешков крови Автоматическая медицинская высокочастотная машина сварки

JINGSHUN гидравлическая машина для тиснения кожаных изделий

Популярная распродажа воздухонепроницаемая Коммерческая холодильная установка сварочная машина с резиновым уплотнением

Высококачественный изолированный контейнер для холодильного мобильного оборудования сменный клеевой аппликатор двойной Угловой сварочный аппарат

Точечные товары высокого качества сварщик ПВХ Магнитный резиновый сварочный аппарат портативный для резиновая прокладка

Портативный удобный холодильник уплотнитель резиновый Мини ПВХ прокладка сварщик ручной дверной прокладки сварочный аппарат

Новые поступления

Новинки товаров от производителей по оптовым ценам