Вкладчик лопатка капельница Boba оборудование для производства перламутрового чая из тапиоки

- Категория: >>>

- Поставщик: Henan Gondor Equipment Material Co. Ltd.Henan Ltd.

Сохранить в закладки 1601279845741:

Описание и отзывы

Характеристики

Introduction

The Popping boba machine also known as the juice ball machine or pearl ball machine, is a popular food processing equipment used to make juice popping beads commonly found in milk tea and other drinks. These popping beads release juice when they pop in the customer's mouth, adding interest and taste diversity to the drink.

Application

1. The popping bead machine is not only suitable for milk tea shops, but also can be used in dessert shops, ice cream shops, restaurants and bars, etc., adding innovative and interesting elements to various drinks and desserts.

2. The popping bead machine is mainly suitable for the catering service industry, food processing enterprises, etc.

Features

1. Can continuously produce a large number of juice beads, greatly improving production efficiency

2. Wide range of application, able to handle various types of liquid materials

3. The machine design meets food safety standards and is easy to clean and maintain

4. With a human-machine interface, easy to operate.

Paramater

| Model | Voltage | Power | Boba size | Output | Pressure | Size | Weight |

| GD-BAOM | 380V 50HZ | 2KW | customize | 30-50kg/h | 0.5-0.6Mpa | 2600+750*1880mm | 230kg |

Q1. What is the working principle of the milk tea popping bead machine?

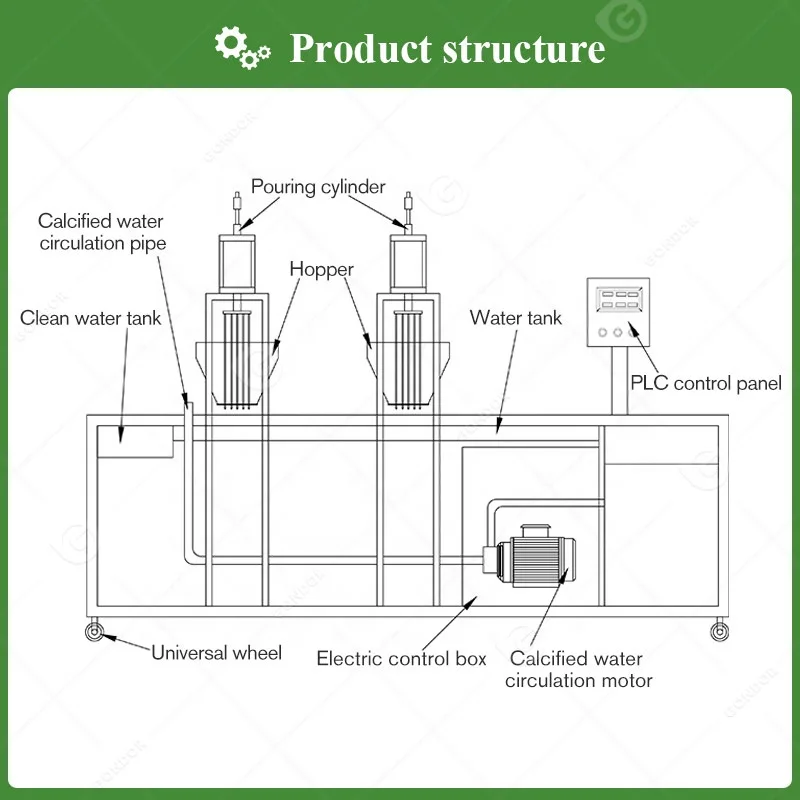

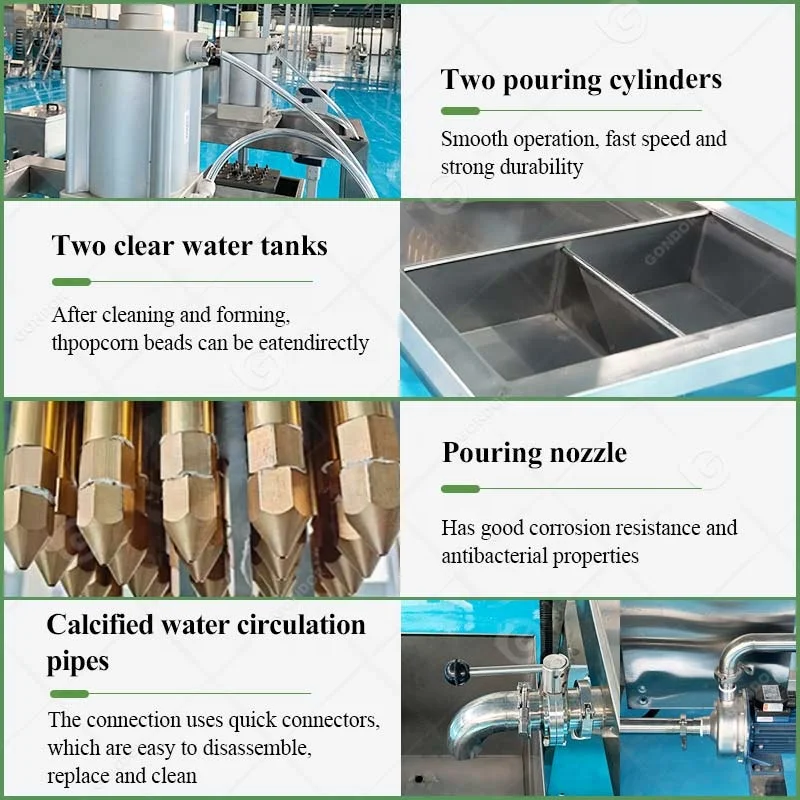

A: The milk tea popping bead machine usually makes popping beads through injection and coagulation technology. The machine injects the flavored and colored sodium alginate solution into the calcium ion solution through the injection head, and the sodium alginate reacts with the calcium ions to quickly form coagulated beads.

Q2. What ingredients are needed to make popping beads?

A:The main ingredients include sodium alginate and calcium salt solution. In addition, food coloring and flavoring agents can be added to provide different colors and flavors.

Q3. How to ensure the quality of popping beads?

A:The key to ensuring the quality of popping beads is to use high-quality raw materials and accurately control the proportions and conditions during the production process. Ensuring the correct concentration of sodium alginate and calcium salt solutions, as well as adjusting the injection speed and temperature of the machine, are important steps to ensure the consistency and quality of the final product.

Q4. How long does it take to make popping beads?

A: Generally speaking, the entire process from raw material preparation to popping beads can be completed in a few minutes. The specific time depends on the machine settings and the batch size produced. Commercial machines are usually designed for fast production to meet high-demand commercial environments.

Q5.How to clean and maintain the bubble tea popping machine?

A: Cleaning and maintenance work includes regular cleaning of all parts of the machine, especially the parts that come into contact with the raw materials. Use a mild detergent and clean water to rinse and ensure that there is no residual material. In addition, regularly check the various moving parts of the machine to ensure that there is no wear and damage.

Installing waterproof membrane to reduce dust and water pollution

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Delivery Time

For stock type, we can send within 48hrs after confirming order.

For customized type , delivery date need to be negotiated before taking order.

1. 24 hour communication service.

2. Fast logistics will provide you a smooth delivery service.

3. One-year warranty and lifetime technical support.

4. New design or product recommendation.

5. Attend international Fair to negotiate with customer face to face.

6. Offer official invitation if you come to China.

7. Reception service will help you book good hotel.

Похожие товары

Тапиока оборудование для производства жемчуга Боба машина рисовых шариков продажа

Машина cheetos kurkure для приготовления риса

Высококачественный мощный смузи Сверхмощный коммерческий блендер и соковыжималки 110 В 220

Лидер продаж производитель рыбных шариков по низкой цене

Автоматическая газовая машина takoyaki и для бургеров машины производства мяса

Новый тип машины для изготовления жемчужин из нержавеющей стали Tapioca

Машина для производства панировочных сухарей

Новые поступления

Новинки товаров от производителей по оптовым ценам