Лазерная машина для подсчета очков ARGUS CO2 с цифровой системой управления автоматическая Подбрасывание рулона упаковки закусок из Гибкой Пленки

- Категория: >>>

- Поставщик: Wuhan Sunic International Trading Co. Ltd.

Сохранить в закладки 1601280390630:

Описание и отзывы

Характеристики

Laser technology offers a range of applications in the flexible packaging industry, providing precise and efficient solutions. Some key uses of lasers in flexible packaging include:

2. Scoring and Cutting

3. Window opening

Laser technology can be used to create precise and customizable openings or transparent windows in flexible packaging materials.

1. Perforation

Laser technology can be employed for creating micro-perforations in flexible packaging materials. This is useful for controlled gas and moisture exchange, extending the shelf life of packaged products like fresh produce or snacks.

2. Scoring and Cutting

Lasers are effective in scoring and cutting flexible packaging materials with high precision. This is particularly beneficial for creating easy-open features on packaging or for intricate designs, ensuring clean and accurate cuts without damaging the material.

3. Window opening

Laser technology can be used to create precise and customizable openings or transparent windows in flexible packaging materials.

Easy opening

Breathing holes

Window opening

The CO2 Laser Scoring and Perforation System is widely used in the PVC、PE、PET、AOPP、MOPP and composite package materials, shrink sleeve, shrink label easy tearing line high speed laser scoring perforating and some soft packing air permeable hole laser perforating.

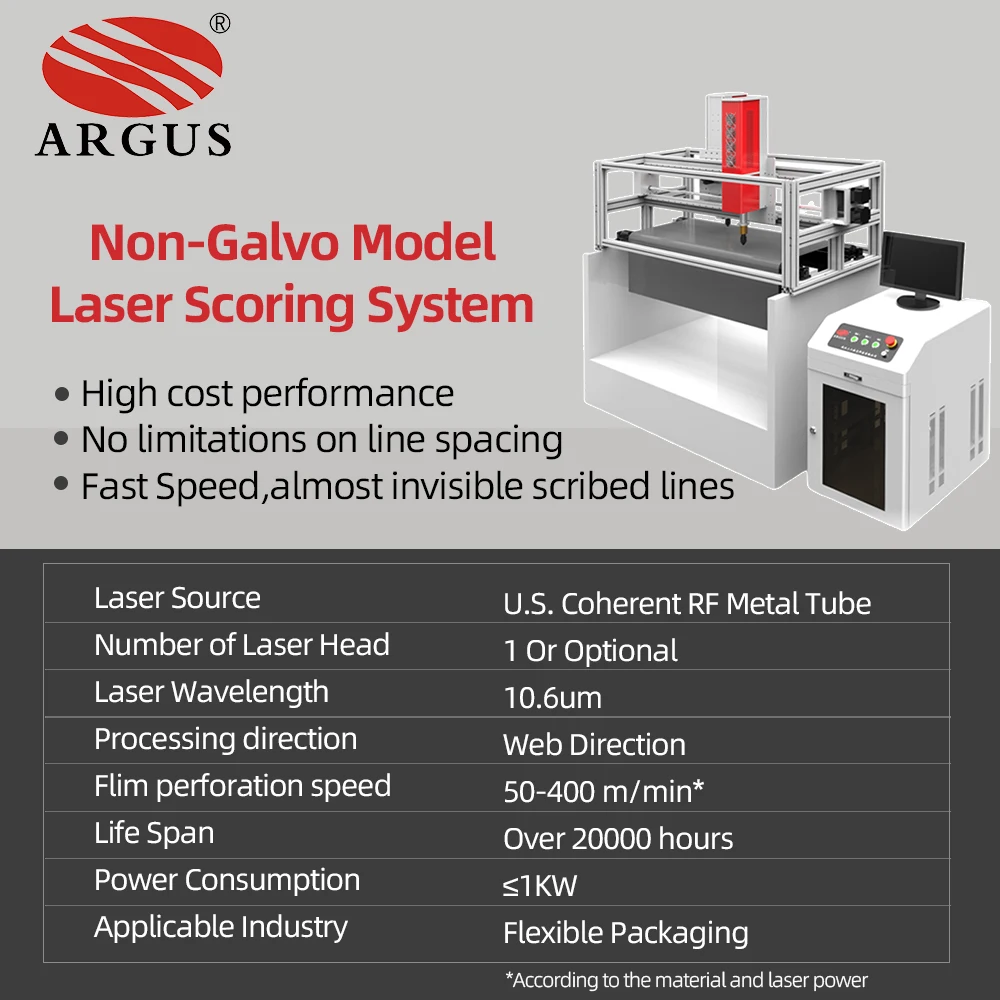

Laser Head Model

Laser scoring in web-direction only

Laser mircro perforation

Multi-head available

Laser power: 30W/55W/70W/100W

Galvo Head Model

Laser scoring in Cross web-direction

Laser micro perforation

Small hole cutting

Multi-head available

Laser power: 55W/70W/100W

Working area: 50x50mm~300x300mm

Laser micro perforation

Small hole cutting

Multi-head available

Laser power: 55W/70W/100W

Working area: 50x50mm~300x300mm

Model | SCM30/SCM55/SCM70/SCM100 |

Laser Power | 30/55/70/100 watts |

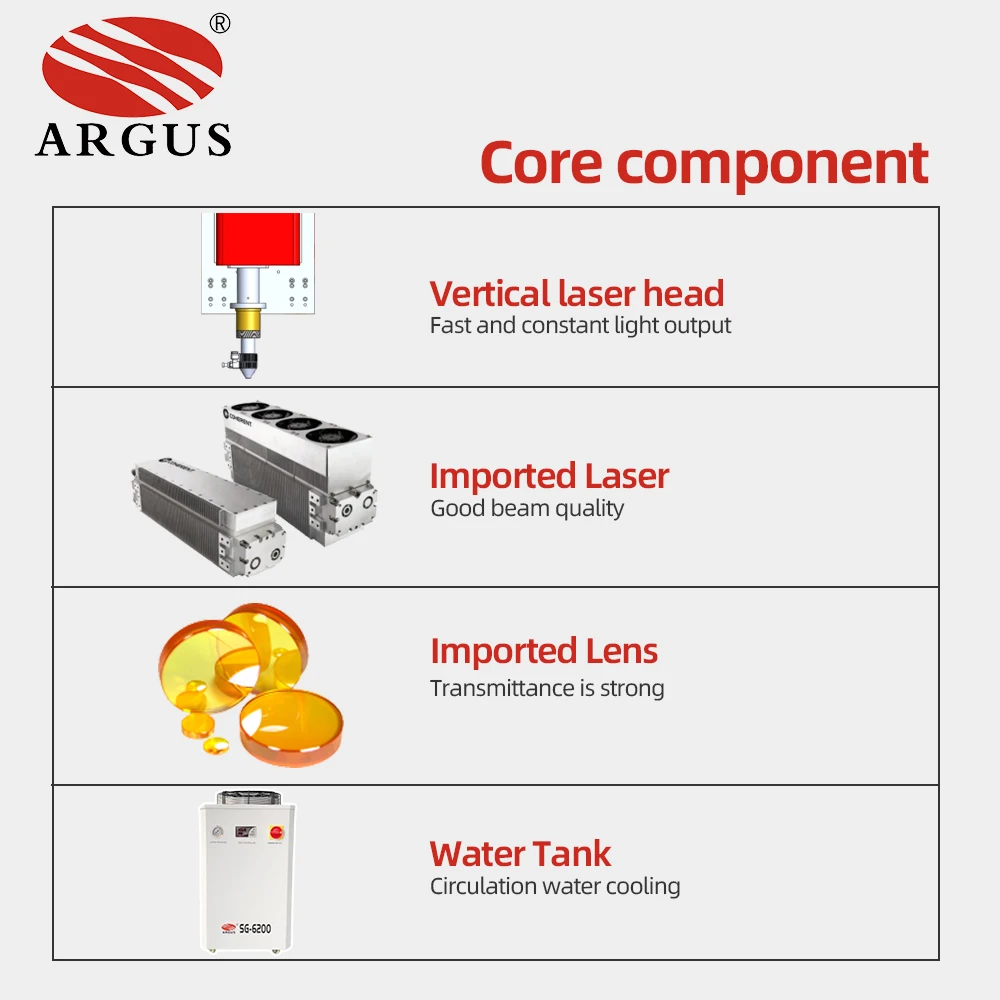

Laser Source | Coherent CO2metal RF Laser source |

Laser Wavelength | 10.6μm |

Laser Frequency | 1kHz~25kHz |

Flim Perforation Speed | 50-400 meters/min(according to the material and laser power) |

Repetition Precision | 0.01mm |

Emulated Encoder | Including |

Control System | ARGUS |

Customized mounting structure, Computer with software, Exhausting Fans, Air Pump | |

Power Supply | 110V~220V/50Hz~60Hz |

Cooling Way | Air/water Cooling |

Multi-head | Avaible according to the request |

Model | SCM55/SCM70/SCM100 |

Laser Power | 55/70/100 watts |

Laser Source | Coherent CO2metal RF Laser source |

Laser Wavelength | 10.6μm |

Laser Frequency | 1kHz~25kHz |

Galvo Head | High speed galvo scanner |

Idle Marking Speed | 3000mm/s |

Flim Perforation Speed | 50-280 meters/min(according to the material, laser power and processing design) |

Repetition Precision | 0.01mm |

High Precision Sensor | Japanese RGB Sensor Eye Mark Reader ( Response time 200us) |

Emulated Encoder | Including |

Control System | JCZ/BSL |

Customized mounting structure, Computer with software, Exhausting Fans, Air Pump | |

Power Supply | 110V~220V/50Hz~60Hz |

Cooling Way | Air/water Cooling |

Multi-head | Avaible according to the request |

Laser perforation advantage:

1) Using fast laser perforating, holes are protective due to the round shape burning melt, not easy break.

2) High-speed detection, uniform hole size, adjustable hole spacing, any direction.

3) Circulating water cooling of the galvanometer control board, continuous high-speed (50-280m/min) operation, low failure rate.

2) High-speed detection, uniform hole size, adjustable hole spacing, any direction.

3) Circulating water cooling of the galvanometer control board, continuous high-speed (50-280m/min) operation, low failure rate.

Laser Perforation | Mechanical gear punching | |

Perforation Direction | Any direction | One direction |

Error Accuracy in high speed | < 0.1-0.5mm | < 1-1.5mm |

Perforation speed | 50-280meters/min | 100-180meters/min |

Hole diameter | Same size, min 0.1-0.3mm | not uniform |

Holes distance | Always keep same distance(min 0.3mm) | not uniform |

All Holes quality | Very uniform | Easy change shape during highspeed working, not uniform |

Consumables part | No consumption parts | Change gears always |

Application | Cut holes, lines and so on . | Just can cut holes |

About Sunic Group

Wuhan Sunic Group are a professional laser machines and solar panel products lines equipment manufacturer since 1998.We are specialized in design, research, manufacture, sales and service for laser machines. Sunic Group would like to be customer's technical consultant, support in laser&solar equipment to make further development and progress together.We supply customized solution for different materials processing , such as invitation cards, wedding cards, pop up cards, Pop up books,candy box,paper products,acrylic, PMMA, LGP, jeans wash,leather, Fabric,textiles,wood,MDF,laminate materials,marble, package film, metalp, plastic products and so on.

What kind of laser machine and model should I choose?

You can tell us your processing material, working size and detail requirement, detail work by picture or video so that we canjudge whether our machine can meet your need.

What kind of materials does the laser machine can process?

We have different laser machines, such as Fiber laser, CO2 Laser, UV Laser, Green Laser. Normally fiber laser can process metal and plastic. CO2 laser is for processing non-metallic materials, such as Acrylic, PMMA, Wood, Glass, Leather, Jeans, Paper, Textiles Garments and so on. UV laser and green laser are also called cold laser source, they are usually used for plastic, glass, crystal and some special processing job.Is it easy to operate?

We will send you manual and guide video in English, I can teach you how to operate the machine. lf you still can not learn how to use it, we can help you by Team viewer online help software. Or we can talk by phone email or other contact ways.

What s your guarantee in case the machine breaks down?

The machine has one year guarantee. If it breaks down, generally speaking our technician will figure out what the problem may be, according to client's feedback. Parts except for consumable parts will be replaced for free if the problems are caused by quality fault.

How will you do the after- sale service?

We will firstly check your problems online through Teamviewer, E-mail, Whatsapp or other contact way, if it is easy to handle it, we will guide you onlinet to fix it or send you the spare parts for replacement.

What is your equipment lead time?

Fiber laser marking machine lead time is around 7 working days.CO2 laser engraving&cutting machine lead time is around 2-3 weeks. 3D dynamic CO2 laser marking machine lead time is around 10 working days.

How will you do the package and shipping?

All of our equipment are packed in export standard cases. Express, air shipping, sea shipping are all available.

Похожие товары

Небольшой бизнес идея 20 Вт 30 50 волоконный лазерный маркировочный принтер нержавеющая сталь Золото Серебро Ювелирная машина

Металлическая этикетка лазерная маркировочная машина из нержавеющей стали и гравировальная Машина пластиковая маркировка

187 359,21 ₽ - 192 869,78 ₽

Портативный УФ-лазер с воздушным охлаждением по низкой цене 355nm

220 422,60 ₽ - 275 528,25 ₽

Волоконно-лазерная маркировочная машина для ювелирных изделий 20 Вт волоконно-лазерная металла и резки

152 091,60 ₽ - 176 338,08 ₽

Портативная машина маркировки лазера волокна портативная для металлической пластины

126 743,00 ₽ - 146 581,03 ₽

20 Вт 30 автоматическая ручка конвейерная лента Raycus Max IPG волоконный лазерный маркер гравер Etcher гравировка маркировочная машина

20 Вт 30 50 волоконно-лазерная маркировочная машина клавиатура лазерная

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $