Одиночная пластиковая линия гранулирования из АБС пластика PMMA TPU EVA PP PS PC

- Категория: >>>

- Поставщик: Zhangjiagang Regulus Machinery Co. Ltd.

Сохранить в закладки 1601280673732:

Описание и отзывы

Характеристики

Product Description

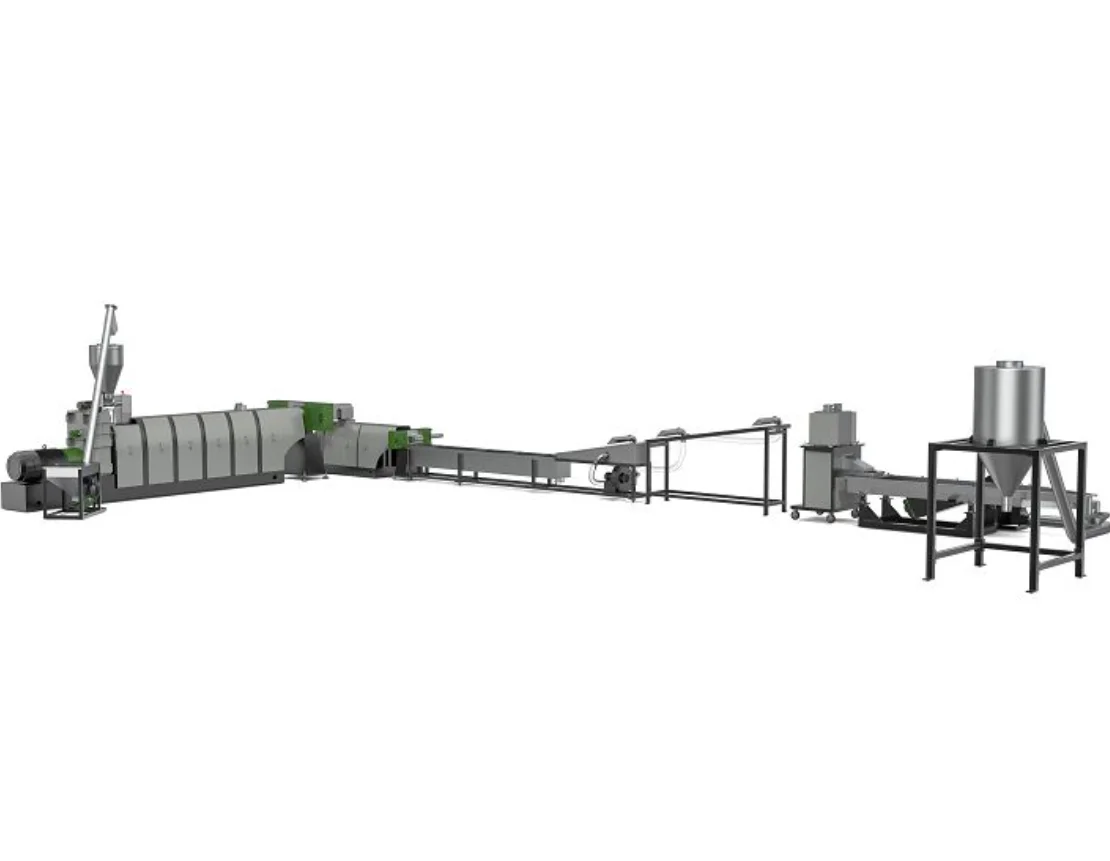

Waste Plastic Pelletizing Granulating Recycling Line

The waste plastic pelletizing recycling line mainly includes two type:

Soft plastic granulating pelletizing recycling line and Hard plastic granulating pelletizing recycling line.

Application

Type 1: Soft plastic granulating pelletizing recycling line

The Granulator Machine is a soft plastic granulating pelletizing recycling line designed for soft plastic articles.

It could provide the excellent re-pelletizing and recycling solution for film, raffia, filament, woven bag and nonwoven fabric and other consumed / post soft or rigid plastic.

Our Plastic Recycle Granulator Machine/pellet making machine has a wide application in PE, PP, CPP, BOPP, PS, PPS, EPS, ABS, PA, PLA, PET waste plastic materials recycling field.

These recycling granules are further processed into various plastics products by blowing, injection and extrusion.

The Granulator Machine is a soft plastic granulating pelletizing recycling line designed for soft plastic articles.

It could provide the excellent re-pelletizing and recycling solution for film, raffia, filament, woven bag and nonwoven fabric and other consumed / post soft or rigid plastic.

Our Plastic Recycle Granulator Machine/pellet making machine has a wide application in PE, PP, CPP, BOPP, PS, PPS, EPS, ABS, PA, PLA, PET waste plastic materials recycling field.

These recycling granules are further processed into various plastics products by blowing, injection and extrusion.

Type 2:Hard plastic granulating pelletizing recycling line

This type pelletizing recycling system provides best solution for PE, HDPE, LDPE LLDPE, PP, PS, ABS, PVC, PC,PET, PA and many other rigid plastic regrind recycling.

Recycling of HDPE and PP bottles, containers and thermoforms is becoming particularly important section of the recycling market.

These recycling granules are further processed into various plastics products by blowing,injection and extrusion.

Recycling of HDPE and PP bottles, containers and thermoforms is becoming particularly important section of the recycling market.

These recycling granules are further processed into various plastics products by blowing,injection and extrusion.

Main Features

Material feeding type | Two kinds feeding method: 1. Belt Conveyor 2. Screw Loader | ||||||

Compactor Type | Soft plastic bags, woven bags and waste film can be directly put into compactor granulation line without crushing. | ||||||

Extruder quantity | Single stage extruder and double stage extruders can be used according to user's requirement or raw material dirty moisture condition. | ||||||

Granules cutting type | Three kinds pellets cutting method: 1. Water ring face cutting 2. strip noodle type cutting 3.hot cutting | ||||||

Electric control | The main engine is equipped with full automatic control cabinet and PLC operating system. It is easy to operate and has stable | ||||||

Advantages | Low energy consumption, remarkable energy saving effect, high output, mechatronics. Plastic granulation. | ||||||

Specification

Single Stage Granulating Pelletizing Recycling Line | ||||||||

Model | Extruder Power(KW) | Screw Diameter(mm) | Agglomeration Power(KW) | Productivity(kg/h) | ||||

SFS-75 | 45 | 75 | 30 | 100-150 | ||||

SFS-85 | 55 | 85 | 37 | 150-250 | ||||

SFS-100 | 90 | 100 | 55 | 250-350 | ||||

SFS-130 | 132 | 130 | 90 | 450-500 | ||||

SFS-160 | 160 | 160 | 110 | 500-600 | ||||

SFS-180 | 250 | 180 | 185 | 900-1100 | ||||

Double Stage Granulating Pelletizing Recycling Line | ||||||||

SFS-85 | 55+22 | 85+85 | 37 | 150-250 | ||||

SFS-100 | 90+30 | 100+100 | 55 | 250-350 | ||||

SFS-130 | 132+45 | 130+130 | 90 | 450-500 | ||||

SFS-160 | 160+55 | 160+160 | 110 | 500-600 | ||||

SFS-180 | 250+75 | 180+200 | 185 | 900-1100 | ||||

Hard plastic granulating pelletizing recycling line

Single Stage Granulating Pelletizing Recycling Line | ||||||

Model | Extruder power(KW) | Screw diameter(mm) | Productivity(kg/h) | |||

SJ-90 | 55 | 90 | 150-200 | |||

SJ-100 | 75 | 100 | 200-250 | |||

SJ-120 | 90 | 100 | 250-350 | |||

SJ-130 | 132 | 130 | 450-550 | |||

SJ-160 | 160 | 160 | 650-800 | |||

SJ-180 | 250 | 180 | 800-1000 | |||

Double Stage Granulating Pelletizing Recycling Line | ||||||

SJ-90 | 55+22 | 90+90 | 150-200 | |||

SJ-100 | 75+30 | 100+100 | 200-250 | |||

SJ-120 | 90+37 | 120+120 | 250-350 | |||

SJ-130 | 132+45 | 130+130 | 450-550 | |||

SJ-160 | 160+55 | 160+180 | 650-800 | |||

SJ-180 | 250+75 | 180+200 | 800-1000 | |||

FEATURES AT A GLANCE

Soft plastic granulating pelletizing recycling line

Soft plastic granulating pelletizing recycling lineis equipped with compacting machine which pre-compact the soft plastic film bags into smaller granules, then easily feed into screw barrel of extruder, its efficiency is high and can improve production capacity. It has vacuum exhausting system on extruder barrel which can fully vent the moisture in the material and hence the final granule quality will be very perfect. The end of screw barrel is equipped with double station fast speed hydraulic non -stop screen changer which can efficiently filter out the dirty in the plastic melt. The pelletizing adopts water cooling pelletizing which is easier to operate, and the shape and appearance of granule is good.

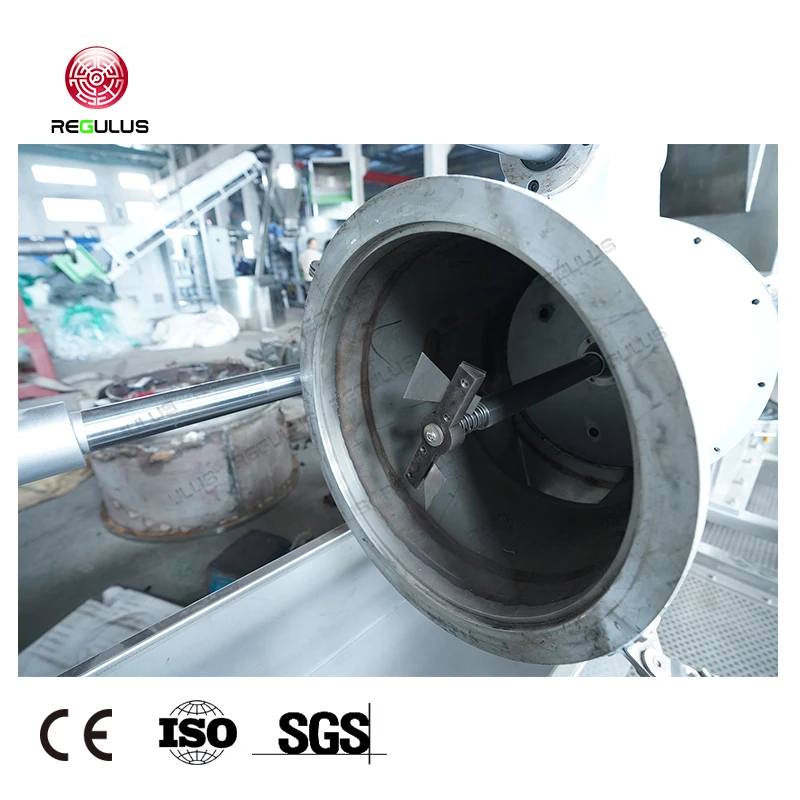

Force compactor machine

High speed rotary,compactor,plastify the film/bags flakes.

Temperature protector, if the temperature is too high will automatic start the water cooling the compactor base With amper meter detecting the compactor motor amper, if the compactor amper too high it will automatic stop the feeding conveyor with water cooling system.

Temperature protector, if the temperature is too high will automatic start the water cooling the compactor base With amper meter detecting the compactor motor amper, if the compactor amper too high it will automatic stop the feeding conveyor with water cooling system.

First Stage extruder (mother stage)

Extruder barrel made by sturdy frame, heavy. No vibrating when machine running; the whole frame where installed the gearbox, motor

and screw has done the milling working. Use 38CrMnAlA making screw, nitriding treatment which can used for long life time.

and screw has done the milling working. Use 38CrMnAlA making screw, nitriding treatment which can used for long life time.

Hydraulic screen changer

Non-stop change screen Board made by 38CrMnAl with forging, heating treatment won’t deform after heating using. Screen changing driven by hydraulic.

Vacuum degassing

Vacuum degassing is Installed on the first Extruder, it can remove the air and humidity from the material.

Second Extruder (baby stage)

Extruder barrel made by sturdy frame, heavy. No vibrating when machine running; the whole frame where installed the gearbox, motor

and screw has done the milling working. Use 38CrMoAlA making screw, nitriding treatment which can used for long life time.

and screw has done the milling working. Use 38CrMoAlA making screw, nitriding treatment which can used for long life time.

Vertical die head cutter

Use SKD-II blade material Die mold Made by the 38CrMoALA material with forging treatment, surface been nitriding treatment and buffing.

Pellets cooling tank, vertical dewatering machine & vibrator machine

S type cooling tank design -high efficiency cooling the granules by 1500 RPM rotor shaft , dewatering machine high speed

dewatering use vibrator machine screen different size.

dewatering use vibrator machine screen different size.

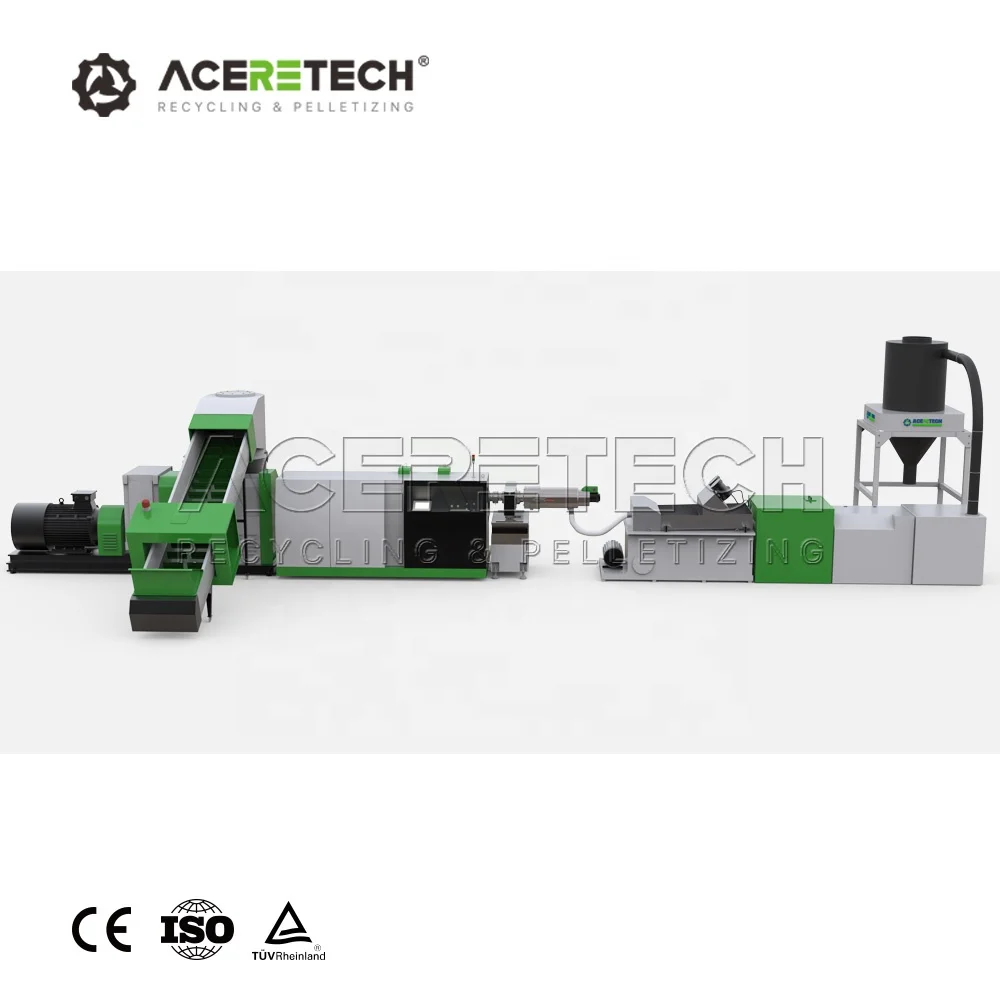

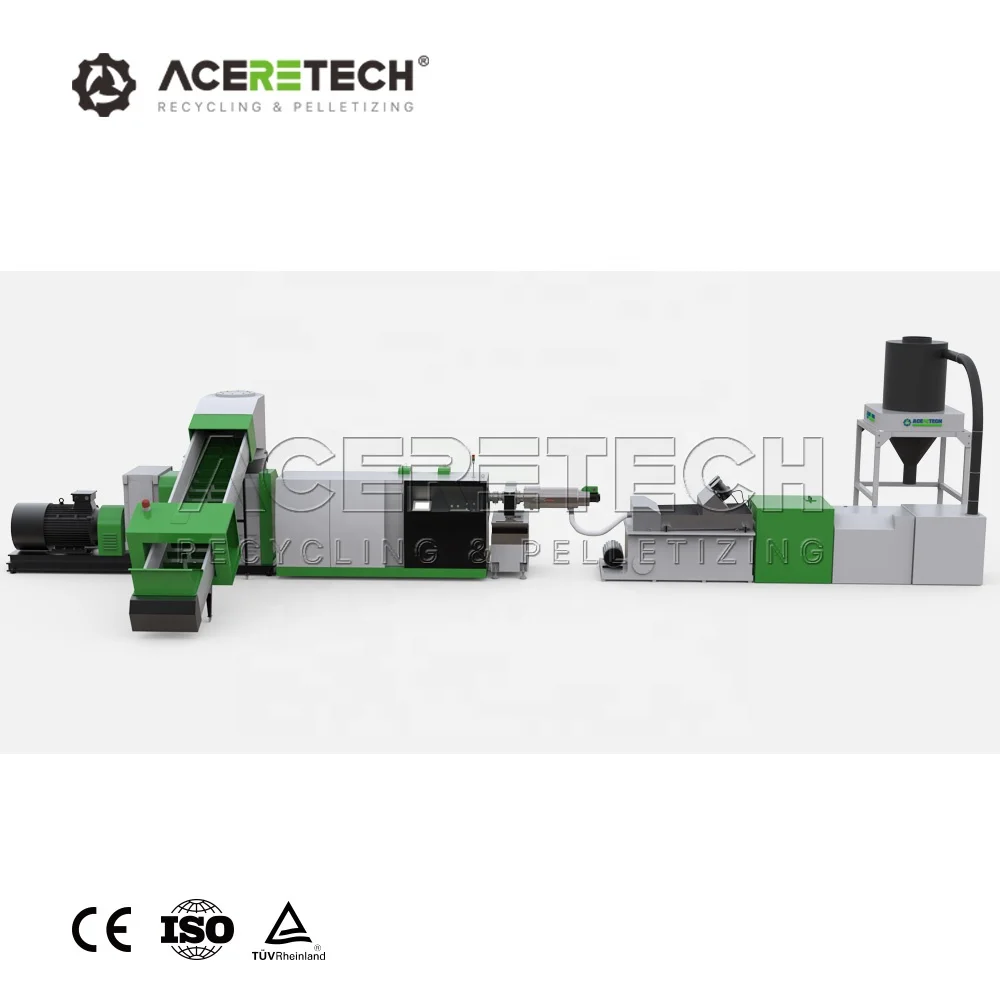

Hard plastic granulating pelletizing recycling line

Hard plastic granulating pelletizing recycling line combines quantitative feeding, high efficiency extruder, different type of

filter and different types of pelletizer by modular design.

filter and different types of pelletizer by modular design.

Feeder

Dosing feeder with inverter controller which ensures the extruder run steadily.

Degassing

Force vacuum degassing system to get rid of the low molecular, moisture and printing ink effectively, make sure high quality output pellets.

Degassing

Force vacuum degassing system to get rid of the low molecular, moisture and printing ink effectively, make sure high quality output pellets.

Extrusion

High efficiency barrel and screw used for extruder with excellent plasticizing result and high output capacity. Adopt high wear resistant alloy material to ensure 1.5 times service life of normal one.

Filter

Plate type, piston type, back flush type and automatic self-cleaning type filter, you have different choice according to impurity

contents in material and your habit.

contents in material and your habit.

Pelletizer

Vertical and horizontal water ring pelletizer, Cutting speed of pelletizer controlled automatically by inverter according to the

pressure of die head, which could achieve the uniform size for output pellets.

Strand noodle pelletizer It is mainly used to cut the strip-shaped plastic cooled by the water tank into small particles.The rotating speed of the pelletizing machine is controlled by the frequency converter to realize speed regulation.

pressure of die head, which could achieve the uniform size for output pellets.

Strand noodle pelletizer It is mainly used to cut the strip-shaped plastic cooled by the water tank into small particles.The rotating speed of the pelletizing machine is controlled by the frequency converter to realize speed regulation.

Plastic granules

Plastic pellets

Cooperation Brand

Packing and Delivery

Sales And Service Network

Certifications

FAQ

1. who are we?

We are based in Jiangsu, China, start from 2015,sell to Domestic Market(20.00%),Africa(15.00%),Southeast Asia(10.00%),North America(10.00%),South America(9.00%),Eastern Asia(8.00%),Eastern Europe(6.00%),Northern Europe(6.00%),Mid East(6.00%),South Asia(4.00%),Oceania(2.00%),Central America(2.00%),Western Europe(1.00%),Southern Europe(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3.what can you buy from us?

Waste plastic recycling machine,plastic extruder,plastic pipe profile extrusion machine,plastic agglomerator,plastic shredder.

4. why should you buy from us not from other suppliers?

ZHANGJIAGANG REGULUS MACHINERY Co., Ltd. is a group company. We are a professional manufacturer of plastic recycling machines and plastic extrusion lines. With more than 20 years experience.

We devote ourselves to the development, research and production of plastic machinery in China.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Portuguese,Russian.

We are based in Jiangsu, China, start from 2015,sell to Domestic Market(20.00%),Africa(15.00%),Southeast Asia(10.00%),North America(10.00%),South America(9.00%),Eastern Asia(8.00%),Eastern Europe(6.00%),Northern Europe(6.00%),Mid East(6.00%),South Asia(4.00%),Oceania(2.00%),Central America(2.00%),Western Europe(1.00%),Southern Europe(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3.what can you buy from us?

Waste plastic recycling machine,plastic extruder,plastic pipe profile extrusion machine,plastic agglomerator,plastic shredder.

4. why should you buy from us not from other suppliers?

ZHANGJIAGANG REGULUS MACHINERY Co., Ltd. is a group company. We are a professional manufacturer of plastic recycling machines and plastic extrusion lines. With more than 20 years experience.

We devote ourselves to the development, research and production of plastic machinery in China.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Portuguese,Russian.

Похожие товары

гранулятор для ПЭ ПНД ПВД европейского класса в Китае

гранулятор большой мощности Китай 1 тонна в час для ПВД плёнки

гранулятор для пакетов ПНД ПВД 120 шнек из Китая

гранулятор для полиэтилена плёнок и дроблёнок ПНД ПВД

Машина для производства пластиковых гранул Greenlandplast

5 592 068,40 ₽ - 5 701 716,80 ₽

Линия грануляции ПП ПЭ со стренговой резкой.

Обновленная машина для производства пластиковых грануляторов

1 973 671,20 ₽ - 2 192 968,00 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

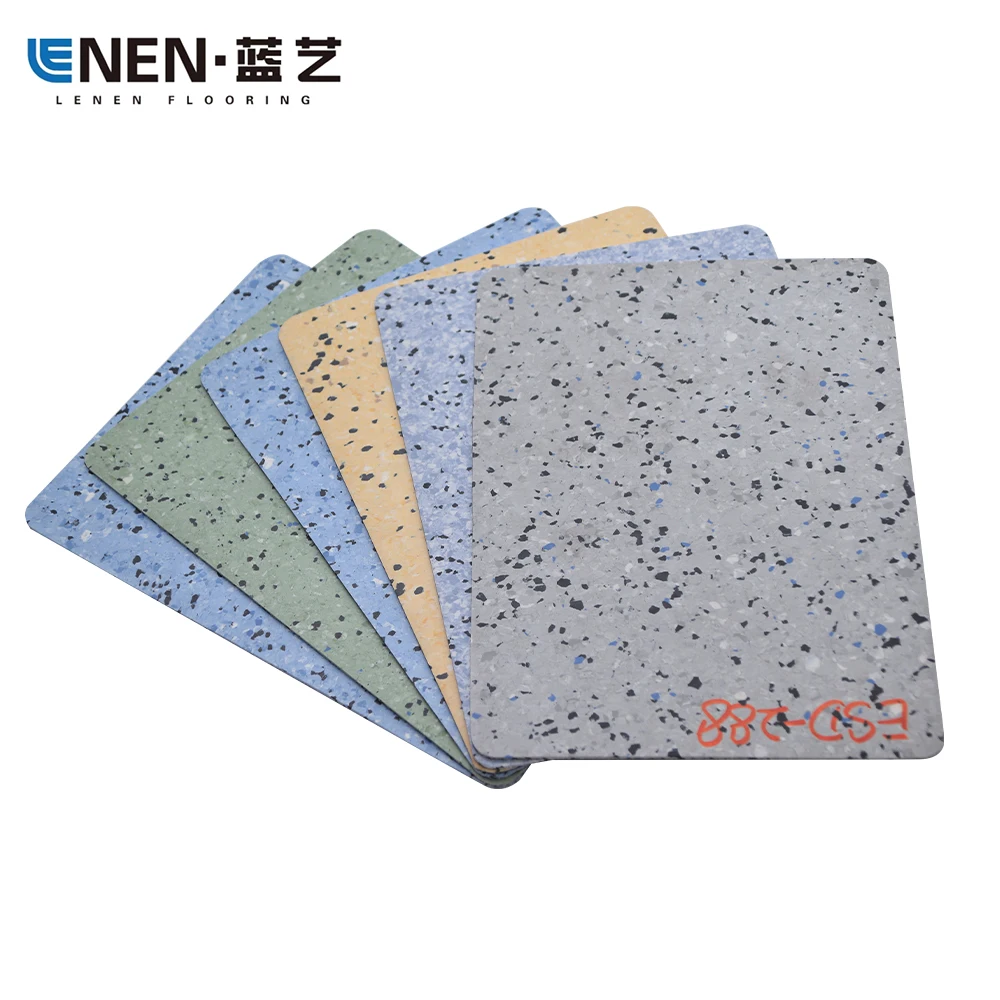

Современный дизайн коммерческий антистатический лист для напольного покрытия из ПВХ толщиной 2 мм эпоксидная проводящая виниловая плитка центров обработки данных пластиковый материал

44-футовый катер для пожаротушения с алюминиевым корпусом и 1500 галлонов водомета

208 009-209 999 $

анти- покупать насекомых полиэтилен экран

2 шт. 50 а 12 в автомобильный лодочный трек переключатель батарея двигатель старт зажигания стартер с нажимной

1,40-1,80 $

OEM пользовательские пружинные зажимы из нержавеющей стали сверхмощный кронштейн для монтажа батареи 9 В прецизионное изготовление листового металла на заказ штамповка

Оптовая продажа двусторонняя велюровая хлопковая Панама для рыбаков взрослых Детская вышивка с логотипом на заказ весенне-летние Мультяшные банты

3-3,95 $

Лучшее качество низкая цена без ГМО шелухи белые семена

Полезные Порошковые напитки подходящие для

7,52-13,23 $