Автоматический палетизатор для водяных бочек сертификат CE трудосберегающий робот паллетизатор

- Категория: >>>

- Поставщик: Shanghai Lilan Packaging Technology Co. Ltd.

Сохранить в закладки 1601281255485:

Описание и отзывы

Характеристики

Product Application

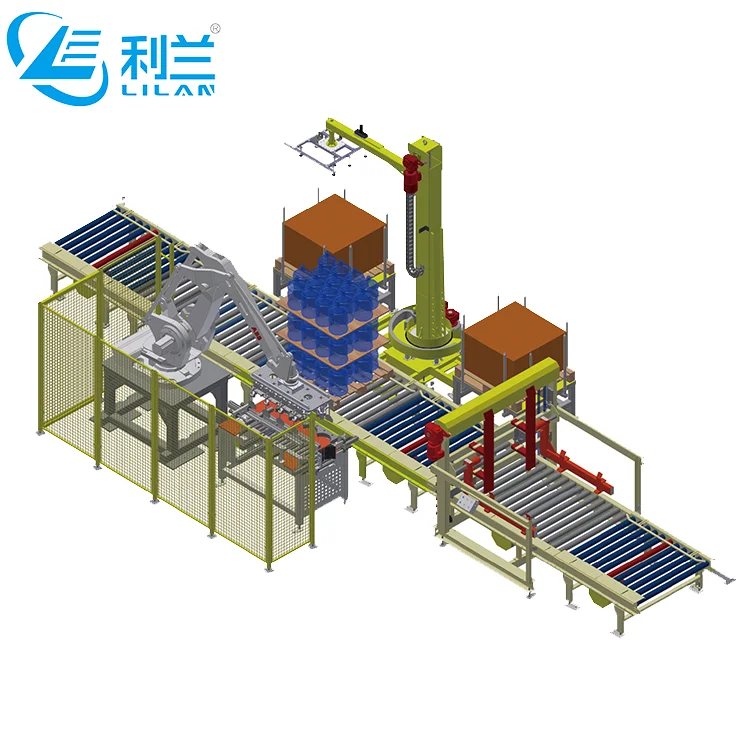

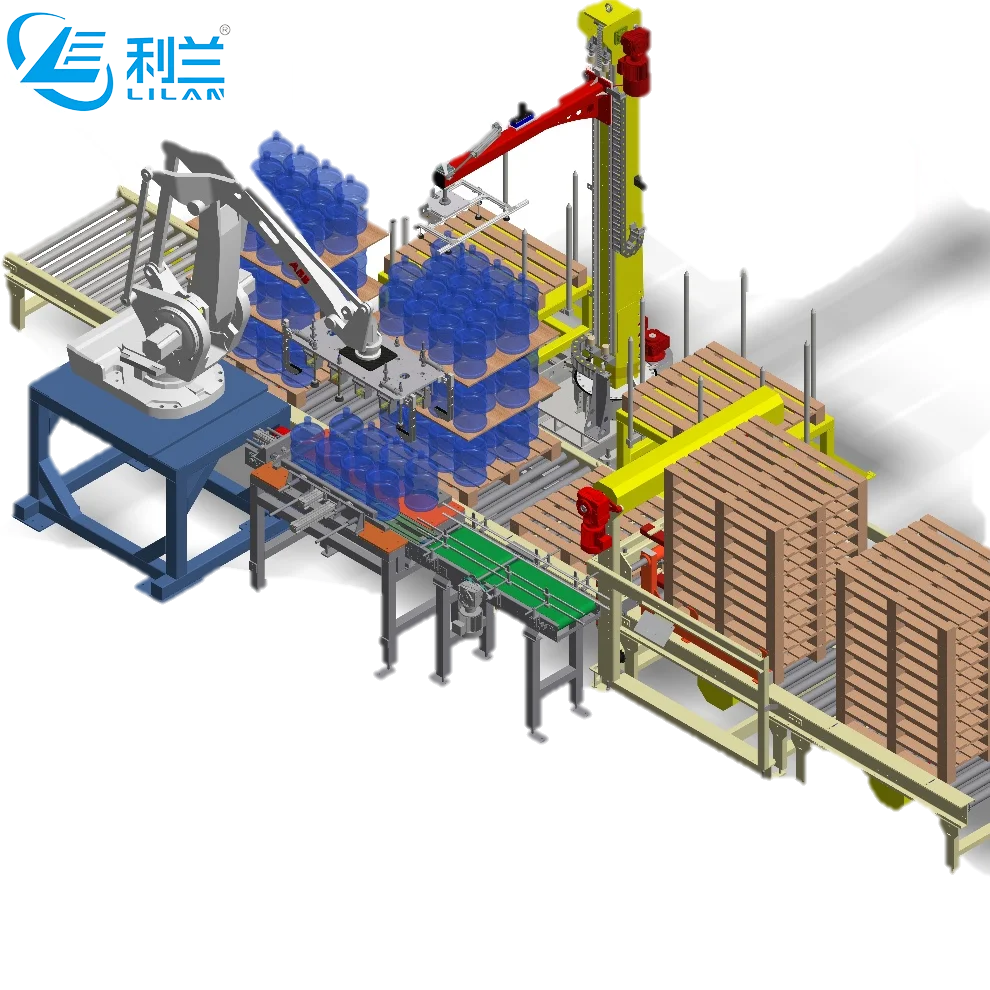

High efficiency automatic robotic palletiser for stacking, palletizing robot, palletizer can be used in any production line, providing intelligent, mechanization for production site. It is a palletising logistic system which can be used in the industries of beer, water, soft drink, milk, beverage and foodstuff etc. It is widely used for cartons, plastic crates, bottles, bags, barrels, shrink wrapped products and cans etc.

SPECIFICATIONS FOR AUTOMATIC ROBOT PALLETIZER | ||||||

Robot arm | Japanese brand robot | Fanuc | Kawasaki | |||

German brand robot | KUKA | |||||

Switzerland brand robot | ABB | |||||

Main performance parameters | Adjust according to products and arrangement per layer | |||||

Weight | About 8000kg | |||||

Applicable product | Cartons, cases, bags, pouch bags | Containers, bottles, cans, buckets etc | ||||

Power and air requirements | Compressed air | 7bar | ||||

Electric power | 17-25 KW(Customized) | |||||

Voltage | 380v | 3 phases | ||||

Robot Arm | ABB/KUKA/FANUC | ||||

PLC | Siemens | ||||

VFD | Danfoss | ||||

Servo Motor | Siemens | ||||

Pneumatic Sensor | SICK | ||||

Pneumatic Components | FESTO | ||||

Touch Screen | Siemens | ||||

Low Voltage Apparatus | Siemens | ||||

Main Features

1) Simple structure, easy in installation and maintenance.

2) Adopting advanced, world-famous brand components in pneumatic parts electric parts and operation parts.

3) When there is some change about the production line, just need to modify the software program.

4) Running in a high automatization and intellectualization, no pollution

5) Robert Palletizer takes less space and is more flexible and accurate compared to the traditional palletizer.

6) Reducing a lot of labour and labour cost, more productive.

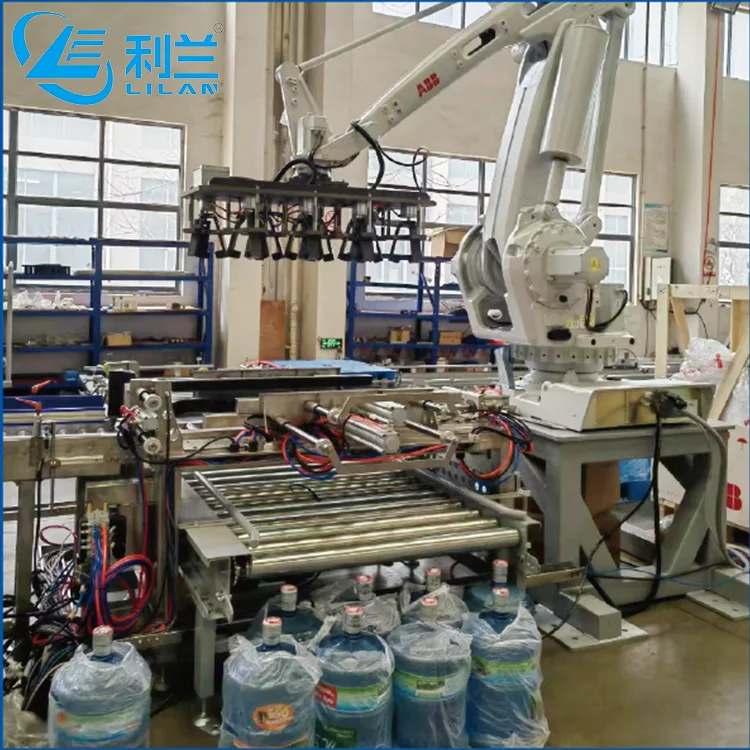

Robot arm of robot palletizer

Brand: ABB, KUKA, FANUC, KAWASAKI (pic is for reference)

Original: Germany, Japan

Machine parts of robot palletizer

Name: Accelerating belt line

Original: China

There are two belt lines with different speeds. The rear belt line’s speed is over one times faster than the front one (the distance between two boxes can be adjusted by adjusting the speed difference between two belt lines by the frequency converter). Speed differential keeps a certain distance between each box, which is good for steering box. The belt is imported baseband, and the main frame is varnished carbon steel.

Machine Parts of robot palletizer

Name: Arrangement buffer system

Original: China

Arrangement buffer system: the pushing mechanism will arrange the products in order, then the robot will grab the product. There are SMC cylinders in this part.

Robot clamp of robot palletizer

Name: Mechanical gripper

Original: China

This mechanical gripper is designed according to customer's products and arrangements of each layer, different gripper usd for different products.

Machine parts of robot palletizer

Name: Empty pallet dispenser

Original: China

This system can hold 15 empty pallets. Pallets are placed on the pallet conveyor line by cylinders. The main frame is varnished carbon steel.

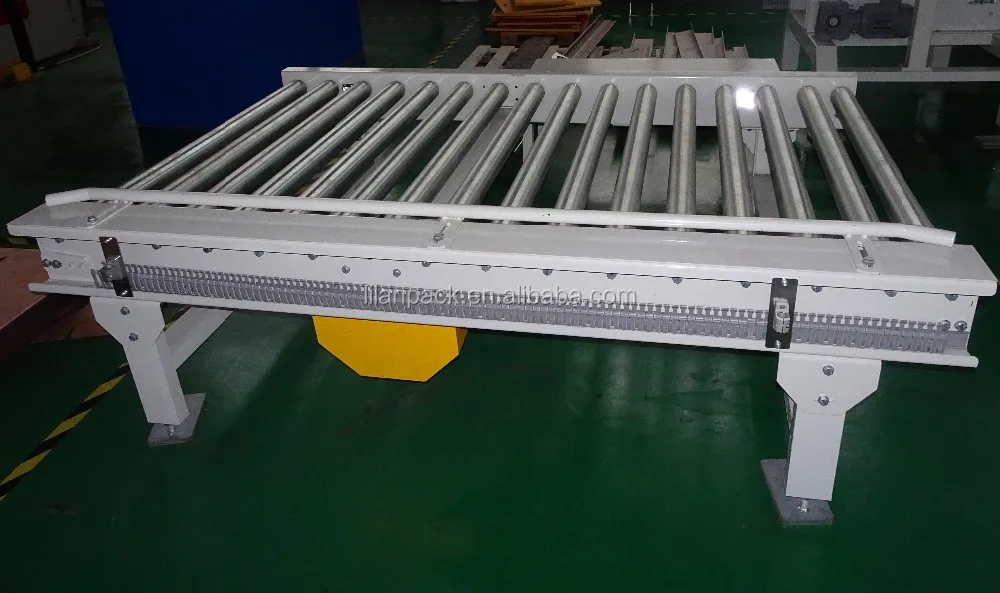

Name: Empty pallet conveyor

Original: China

Roller conveyor consists of heavy-load roller conveyor line, which is used to convey empty pallets and full stack of products to workstation of the forklift.

The frame is made of carbon steel plate, thickness is no less than 5 mm;

Conveyor use Φ 76 mm double row tooth galvanized roller.

Holder: use channel steel welding, the anchor USES the steel plate.

Speed: constant speed

Block device adopts pneumatic method

Power supply: 380 v / 50 hz, power 0.75 KW, power: 0.75 KW

Machine parts of robot palletizer

The control system is composed of main electric control cabinet, HMI and detection system. PLC: Siemens; touch screen: Schneider; frequency converter: Danfoss; low-voltage apparatus: Schneider; photoelectric sensor: SICK.

1. All European production facilities to ensure outstanding quality

2. Professional engineers with more than 7 years experience, all in readiness

3. Available on-site installation and debugging

4. Experienced foreign trade staff to guarantee instant and efficient communication

5. Provide lifelong technical support

6. Provide operation training if necessary

7. Quick response and in-time installation

8. Provide professional OEM&ODM service

Packaging | ||

Material | Stretch film wrapping and wooden case | |

Weight | 8T | |

Packaging Details | The normal package is wooden box. If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. | |

Value OF THE OFFER

30 days from the date of quotation sent

DELIVERY

Approx. 60 days from order confirmation

PAYMENT

30% as deposit by T/T, 70% paid before shipment by T/T.

INSTALLATION &COMMISSIONING

The seller will dispatch one engineer to the buyer's factory for installation, commissioning and training, The buyer should be responsible for the room and board, the go-back air tickets and visa fee, and the allowance of 100 USD per day for each person each day.

NOTE

1. If delays occur due to the fault of either party involved, then any extracost shall be borne by the party at fault

2. The Customer is responsible for providing continuous supply of quality electricity for the duration of the installation, commissioning and test running, which must be available prior to the arrival of technicians from the Manufacturer.

SAMPLES

sufficient quantity of product samples must be sent byCustomers customers to the manufacturer within 15 days after order confirmation for technical clarification.Delays in sending the required samples may affect the delivery schedule of the machines, of which the Manufacturer bears no responsibility; the cost of sending the samples is at Customer's charge.

GUARANTEES

√ The guarantee covers the replacement f.o.c. of the parts that are comprised in the supply and those

acknowledged to bear manufacturing faults or are materials that contribute to the incorrect function of

the machine

√ Lilan guarantees the products supplied for a 12-month period as of from the date of the startup but

however, not more than 18 months from the date of the relative invoice.

√ As for the electrical and electronic parts, the guarantee lasts for 6 months from the startup date but

however, not more than 12 months from the date of the relative invoice.

√ Merchandise that is supplied under guarantee will be delivered with pre-paid freight and packaging

√ Other relevant guarantees, kindly see the operation and appliance manuals sent with equipment.

Note: All the accurate technical data should be confirmed; in the meantime, the contract is confirmed

Похожие товары

профессиональное изготовление стального лома пресс

YSR-4-300-F промышленный робот паллетизатор

Профессиональные Автоматические робот коробки паллетизатор №

YSR-2-120-F промышленный робот паллетизатор

Машина для производства и упаковки шоколада монет

новый продукт хирургические перчатки упаковочная машина

HONGRUN Дешевые яйцо лоток делая машину для бумаги поддоны поворотные Тип машина продажи

Новые поступления

Новинки товаров от производителей по оптовым ценам