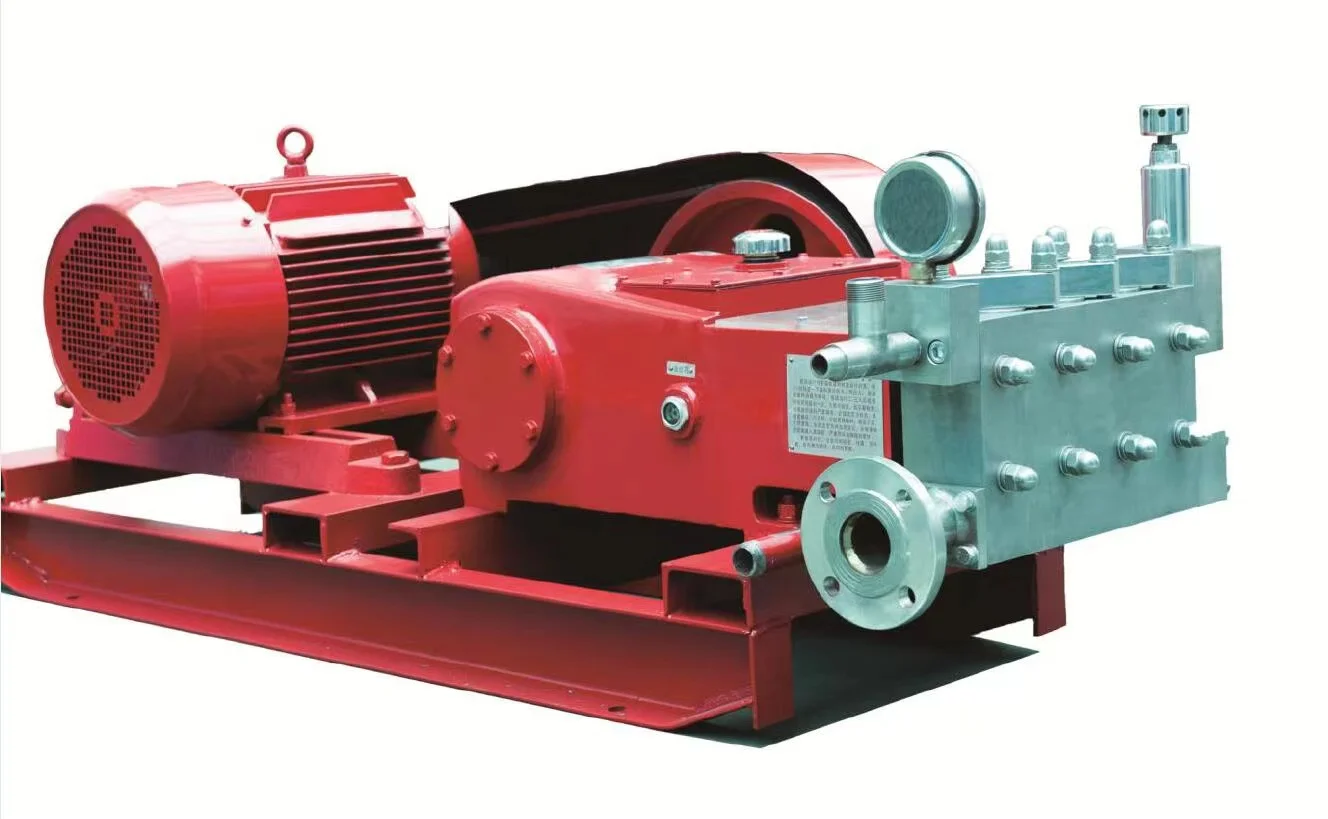

Водяной насос высокого давления 500 бар с необходимыми инструментами для впрыска воды на месторождении

- Категория: >>>

- Поставщик: Wuxi Hercules High Pressure Cleaning Equipment Co. Ltd.

Сохранить в закладки 1601282636227:

Описание и отзывы

Характеристики

Product Description

Cleaning machine fault analysis and elimination

Fault performance | Main reason | Solution | |

| 1 | The power end is abnormal when the pump is running | Water in crankcase causes lubricating oil to emulsify | Change lubricating oil |

Connecting rod bearing wear | Replacement bearing bush | ||

Bearing failure | Bearing replacement | ||

| 2 | Transmission end middle rod oil leakage | The oil level of lubricating oil is too high | Release a little lubricating oil |

Skeleton oil seal damaged aging | Replace the skeleton oil seal | ||

| 3 | Pressure gauge display fluctuation (high pressure hose shaking violently) | The valve or spring is broken | Check and replace |

The seal packing or valve of the pump is badly worn | Check and replace | ||

The spool has impurities | Check and remove impurities | ||

Ultra-high pressure pump water supply is insufficient | Troubleshoot mechanical faults according to water pressure | ||

| 4 | Water pressure alarm | The water tank has no liquid level or the liquid level is very low | Check water supply source |

Y-type filter is blocked | Y-type filter is blocked | ||

Bag filter built-in bag clogging | Clean or replace cloth bags | ||

Low pressure gauge reading above filter | Check pipe pump | ||

The tank float falls off and blocks the outlet | Reattach |

| Cleaning media | Clean Water |

| Power (watts) | 600000 |

| Maximum pressure | 50MPa/500bar |

| Keywords | Oilfield Water Injection |

| Function | Oilfield Water Injection |

| Usage | Oilfield Usage |

Customers from various countries

Customers from Ukraine

Customers from India

Customers from Chile

Customers from Russia

Projects in Kenya

Why choose us?

Похожие товары

DANAU Hochdruckreiniger профессиональная 2800 Psi 190 бары промышленная холодная вода Электрическая Мойка высокого давления

Тройной насос 4200PSI 290bar мойки высокого давления 16.0gpm автомобильный очиститель стальной проволочный шланг

DANAU DCC-23/15 нг 3400psi/235 бар Hidrolavadora Высокого Давления Паровой струйный Очиститель Поверхности промышленный автомойщик высокого давления

NEWLAND (Китай) Портативный 170 бар 180 2600 psi 2600psi бензиновый водяной бластер

DANAU DCC-20/10GRA Hidrolavadora 3000psi/206 бар мойка высокого давления для бензина промышленная автомойка

Дизельный двигатель высокого давления 85 л/мин 1500 бар

DANAU 3600psi/248bar популярная модель бензиновой моечной машины

Новые поступления

Новинки товаров от производителей по оптовым ценам