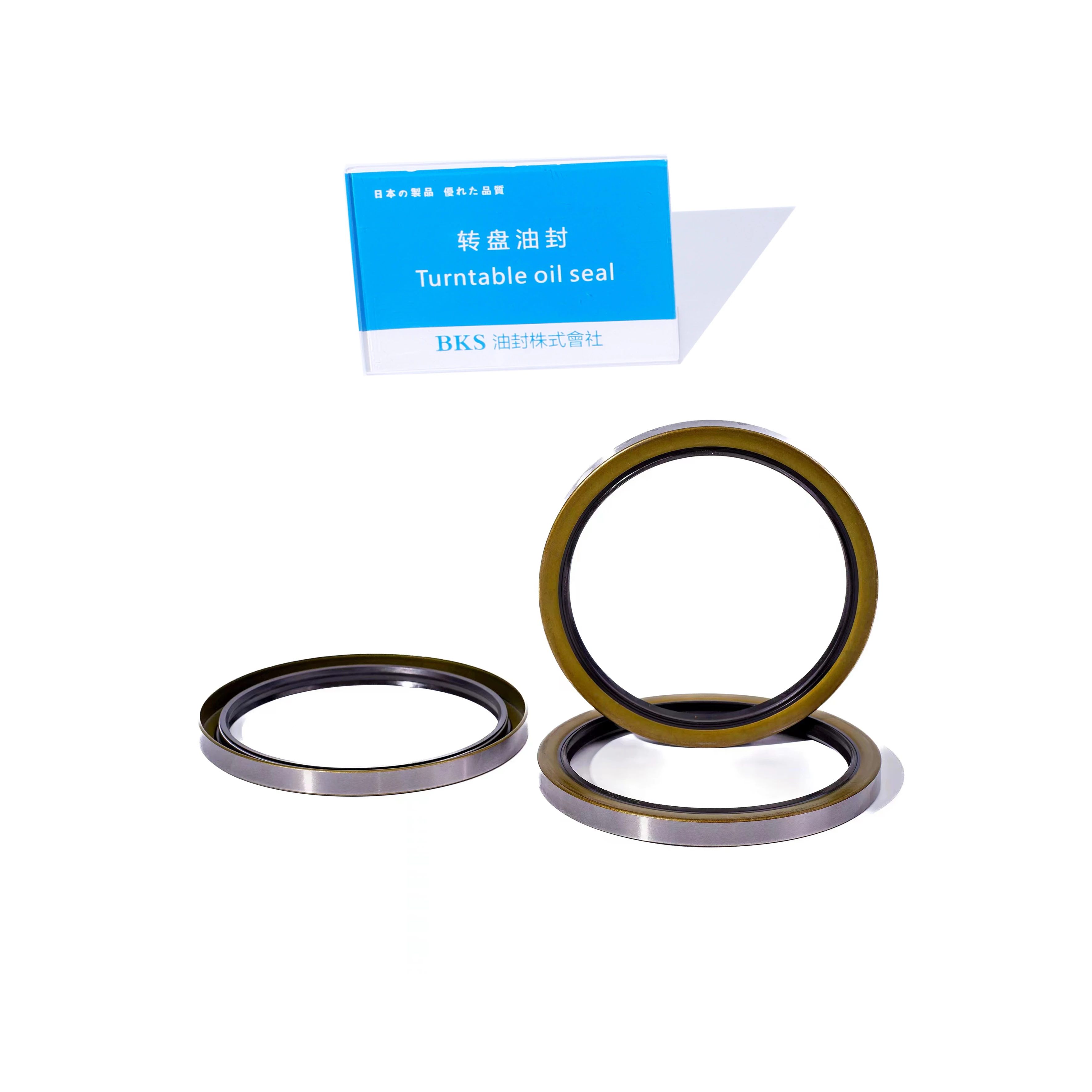

Бренд BKS DH500 7 с завода Прямая продажа уплотнитель поворотного стола вертикальное уплотнение вала 100*125*13 размеры масляных уплотнений

- Категория: >>>

- Поставщик: Ebeck (xiamen) Technology Co. Ltd.Ebeck Ltd.

Сохранить в закладки 1601282894582:

Описание и отзывы

Характеристики

| item | value |

| Place of Origin | Fujian,China |

| Brand Name | BKS |

| Color | Brown |

| Serial Number | AP-4063 |

| Standard Size | 100*125*13 |

| Applicable vehicle type | DH500-7 |

Application scope

The excavator vertical shaft large rotary plate oil seal is mainly used in the rotary mechanism of the excavator to ensure the sealing of the rotary support part, prevent the leakage of lubricating oil and external impurities from entering, and ensure the normal rotation function of the excavator. It is suitable for various types and specifications of excavators, and is one of the important sealing parts of excavators.

Standard materials

Rubber material: Usually use high-quality oil resistant rubber, such as nitrile rubber, fluorine rubber and so on. These rubbers have good oil resistance, wear resistance and elasticity, and can maintain good sealing performance in a variety of harsh working environments.

Characteristics

1. Good sealing: It can effectively prevent the leakage of lubricating oil and external impurities from entering, and ensure the normal operation of the excavator rotating mechanism.

2. Strong wear resistance: In the working process of the excavator, the oil seal will be constantly subjected to friction and wear, so it needs to have high wear resistance to extend the service life.

3. High temperature and low temperature resistance: It can maintain good sealing performance at different working temperatures, and adapt to the work needs of excavators in various environments.

4. Easy installation: the structure of the oil seal is reasonable, the installation is simple and convenient, and it can be quickly replaced and maintained.

Working conditions

1. Working pressure: The oil seal of the vertical shaft of the excavator will bear a certain pressure during the working process, mainly from the pressure of the lubricating oil and the external impact force.

2. Working temperature: The excavator will produce a lot of heat when working, making the working temperature of the rotary mechanism high. At the same time, in a cold environment, the oil seal also needs to be able to work properly.

3. Working environment: Excavators usually work in harsh working environments, such as dust, soil, sand and so on. The oil seal needs to be able to resist the intrusion of these external impurities and maintain good sealing performance.

4. Form of movement: The rotary mechanism of the excavator is a rotary movement, and the oil seal needs to be able to adapt to this form of movement and maintain good sealing performance during the rotation process.

1. How can I get the price?

Please provide the size or photos of seals that you’re looking for, we could quote you accordingly.

2.Can i place the sample order?

Yes. Sample order is also welcome. Please feel free to contact us.

3. The seals I'm looking for is not standard. can i place customization order?

Yes of course. we have professional R&D team. we can make it base on client's design drawing. OEM &ODM order are welcomed.

4.Can you provide a nice OEM branding for this item and color packaging?

Yes, we can.We have our strong design team to give our solution on your branding and package.

5. What is your payment term?

T/T,Western Union,L/C,PalPal and so on.This is negotiable

Похожие товары

Гидравлический поршень PU шток UNS UN масляное уплотнение гидравлическое

Kafuka китайский завод автомобильный NBR резиновый механический гидравлический цилиндр масляное уплотнение высокое качество FKM Резиновое Уплотнение TC

Mingjie уплотнение высокого качества переднего заднего коленчатого вала масляное

SCJY 25x46x8 5 гидроусилитель руля сальник гидравлический резиновый

Хорошее качество национальное уплотнение заднего коленчатого вала сальник для ступицы переднего колеса грузовика 370001A 370003 370031 370025 по заводской цене

KKK BF-KKK TC масляные уплотнения с двойной кромкой NBR FKM механическое сальник 40*58*8 Скелетное высокого качества

LBH LBI Type NBR резиновое масляное уплотнение для механической пылезащитной термостойкой краски

Новые поступления

Новинки товаров от производителей по оптовым ценам