Передвижной троммель для шахтных карьеров установка мойки золота 50 тонн/час передвижной аллювиальный завод

441 189,84-497 752,64 ₽

Сохранить в закладки 1601282946562:

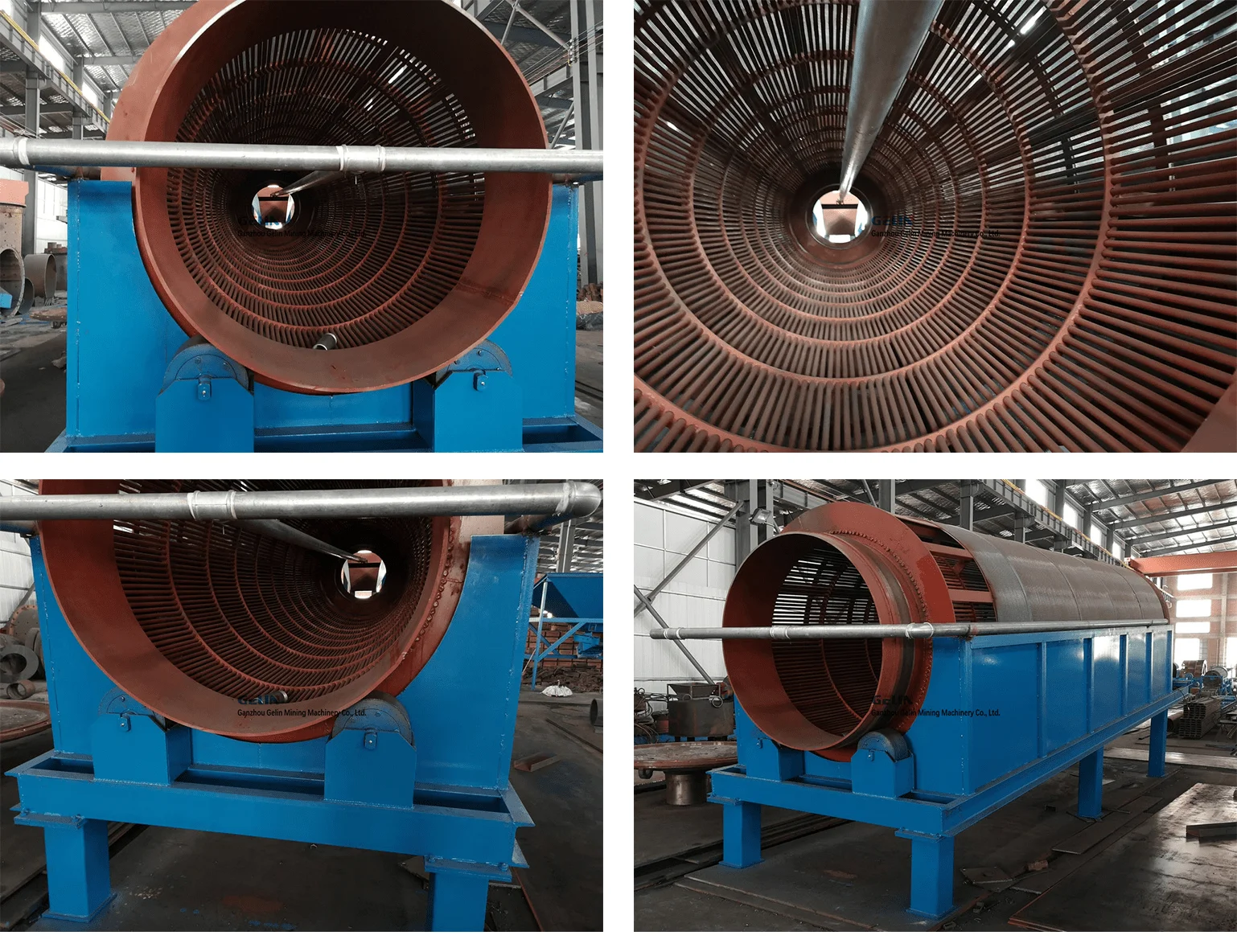

Professional Factory Gold Washing Plant Small And Big Scale Gold Mining Trommel

| Fixed Type Washing Trommel Machine | ||||||||

| Model | Capacity (t/h) | Power(kw) | Screen Diameter (mm) | Screen Length(mm) | Input Size (mm) | Output Size (mm) | Dimension (L*W*H)(mm) | Weight (kg) |

| TW1015 | 50 | 3 | 1000 | 1500 | ≤300 | 0-100 | 2600×1400×1700 | 2200 |

| TW1020 | 100 | 4 | 1000 | 2000 | ≤300 | 0-100 | 3390×1400×2140 | 2800 |

| TW1225 | 160 | 5.5 | 1200 | 2500 | ≤300 | 0-100 | 4146×1600×2680 | 4200 |

| TW1530 | 250 | 7.5 | 1500 | 3000 | ≤300 | 0-100 | 4460×1900×2820 | 5100 |

| TW1545 | 350 | 11 | 1500 | 4500 | ≤400 | 0-100 | 5960×1900×3080 | 6000 |

| TW1848 | 450 | 15 | 1800 | 4800 | ≤400 | 0-100 | 6500×2350×4000 | 7500 |

| TW2055 | 600 | 22 | 2000 | 5500 | ≤400 | 0-100 | 7500×2550×4800 | 9600 |

| TW2265 | 800 | 30 | 2200 | 6500 | ≤400 | 0-100 | 8500×2750×5000 | 12800 |

| Mobile Type Washing Trommel Machine | |||||||

| Model | Capacity (t/h) | Wheel | Water pump | Diesel engine/Electric Motor | Drum Dia. (mm) | Drum Length. (mm) | Screen size (mm) |

| GL510 | 5-15 | 4 | include | Alternative | 500 | <3-20 | 1200 |

| GL615 | 10-20 | 4 | include | Alternative | 600 | <3-20 | 1500 |

| GL715 | 20-30 | 4 | include | Alternative | 600 | <3-20 | 1500 |

| GL815 | 30-40 | 4 | include | Alternative | 600 | <3-20 | 1500 |

| GL1020 | 40-100 | 4 | include | Alternative | 1000 | <3-20 | 2300 |

| GL1225 | 100-160 | 4 | include | Alternative | 1200 | <3-20 | 3000 |

| GL1530 | 150-200 | 4-6 | include | Alternative | 1500 | <3-20 | 4000 |

| GL1545 | 200-300 | 4-6 | include | Alternative | 1500 | <3-20 | 4500 |

| GL1848 | 300-450 | 4-6 | include | Alternative | 1800 | <3-20 | 6000 |

| GL2055 | 400-500 | 4-6 | include | Alternative | 2000 | <3-20 | 9000 |

| GL2265 | 500-700 | 4-6 | include | Alternative | 2200 | <3-20 | 12000 |

Новинки товаров от производителей по оптовым ценам