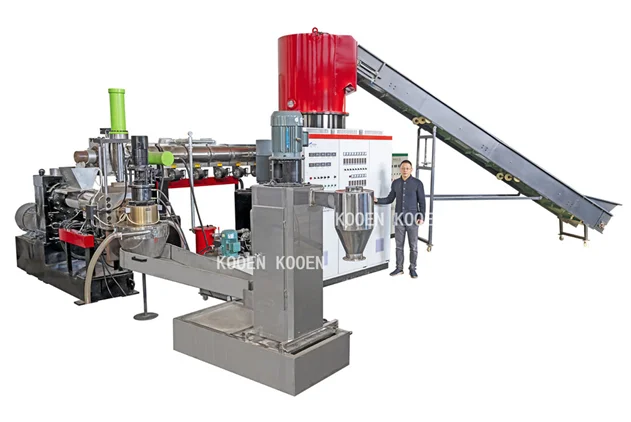

PP PE пластиковые пленки соковыжималка машина пластиковая пленка

- Категория: >>>

- Поставщик: Zhangjiagang Kooen Machinery Co. Ltd.

Сохранить в закладки 1601283117487:

Описание и отзывы

Характеристики

LDPE PP plastic films squeezer machine

Main parameter of plastic squeezer machine:

Model | Capacity (kg/hour) | Motor power (KW) | Screw diameter(mm) | Rotation speed (rpm) | Cutting motor power (KW) | Fan blow power (KW) |

KN-250 | 300 | 75 | 250 | 55 | 4 | 5.5 |

KN-300 | 500 | 90 | 300 | 55 | 4 | 5.5 |

KN-320 | 600-700 | 132 | 320 | 55 | 5.5 | 7.5 |

KN-350 | 800-1000 | 160 | 350 | 55 | 5.5 | 7.5 |

Usage: This is new type film-squeezing machine which is designed by our company. It use squeezing & dehydration principle, after raw material (LDPE agriculture film, LLDPE strength film, and PP woven/big bags, etc) crushing and washed, this squeezer machine can quickly and effectively remove the water. It is easy to increase the subsequent granulating line production capacity.

Advantages of squeezer machine:

1. Low power consumption.

Main motor power between 75-160kw, no need to connection drying pipe system. Compare transitional horizontal dewatering machine + drying pipe system, can save electric consumption 40-50%

2. Small land occupied

3. Low rotation speed, almost no noise

4. Dewatering function is better, final products humidity less than 2%

5. Can greatly increase the subsequent granulating line production capacity

Machine photo | Specification |

Squeezer machine | Main motor power: 75/90/132/160kw

Rotation speed:50rpm

Screw diameter: 250/300/320/350mm

Cutting motor power:4/5.5kw

Cutter rotation speed:380rpm (frequency control by invertor)

Pellets size:≥12mm

Final production humidity: below 2%

Capacity:Around 300-800kg/h

|

Barrel | Material:38CrMoA1A Nitrified Hardness: HV 740 Nitrified thickness: 0.4-0.6 CNC treatment |

Screw |

Material:38CrMoAl Nitrified

Special design on the screw, suitable for process both PE and PP materials.

Hardness: HV ≥ 980

Nitrified thickness: 0.6-0.7 CNC treatment

|

|

Material:38CrMoAl Nitrified CNC treatment

die head hole size: 12-18mm

(process PE and PP, need exchange the die head plate) |

Cutter

| Cutting hood material:stainless steel

Cutting motor and cutting shaft connect directly

Cutting knife quantity:4pieces

Blade material: White steel

Cutter material:SDK-11

Cutting angle:30°

The cover can opening, easy to install/dismount the knives, and easy for maintenance |

Driving part | High quality high torque, low noise, hard surface gear box connected with cooling cycling system outside SPC belt driving efficiency Belt quantity:7 pieces |

Wind transition + silo | Fan motor power:5.5kw

Material of silo: stainless steel Volume of silo: 1M3 |

Platform Handrail | Big area Platform + Handrail, easy for workers to checking machine working condition, and easy for machine maintenance |

Control cabinet | Word famous brand electric components used: ABB invetor Schneider contactor Etc, |

(KOOEN company more plastic recycling machine for reference)

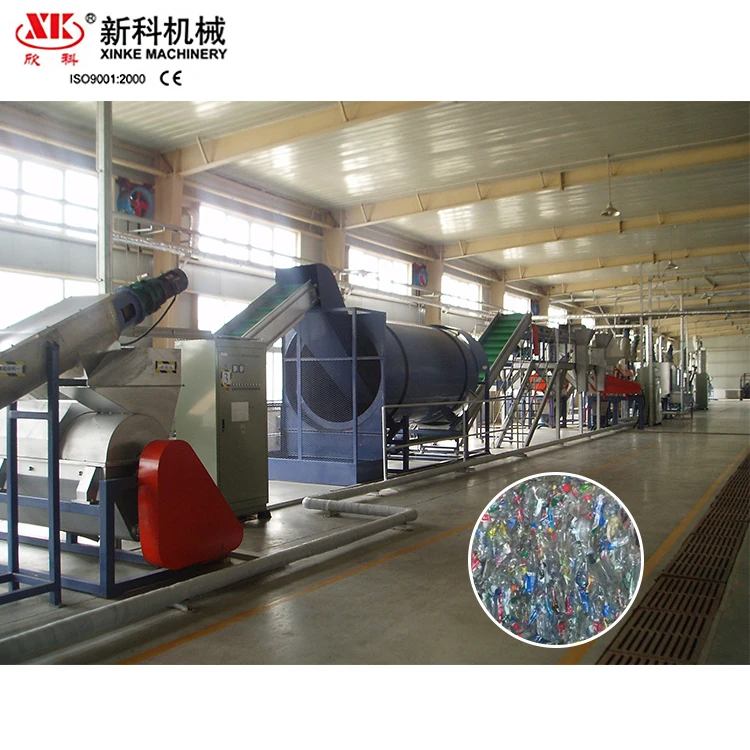

PE/PP film washing line (with squeezer machine)

PE/PP film washing line (with centrifugal dryer)

HDPE, PP bottle(hard plastic) washing line

ZL series single stage compactor granulator

ZL series double stage compactor granulator

SJ series double stage granulator (water ring cutting)

SJ series double stage granulator (pull strip cutting)

For choosing proper machine and saving your time, please read these bellow guides carefully:

1. What material do you want to process on this plastic squeezer machine? PE film? PP bags? or others?

2. What capacity (kg/h) of this plastic squeezer machine?

KOOEN is a leading waste plastic recycling machinery manufacturer in China, dedicated to series waste plastic recycling machine with more than 20 years export experience. If you have related requirement about waste plastic recycling machine/linle, please do not hesitate to let me know...

Note, If you want to see more information (video) of this LDPE/PP film squeezer/squeezing drying machine, please log on our website https://kooengroup.com/pro/plastic-squeezer/

LDPE PP plastic films squeezer machine

Похожие товары

Высокая репутация цена вторичной переработки пластмасс гранулятор

Пластиковые ПЭТ бутылки Лом дробления Стиральная Сушка рециркуляции линии

Линия для переработки ПЭТ бутылок

Китайский Производитель Пластиковых Пэт-Бутылки Хлопья Стиральная Система Дробилка Для Переработки Машина

PP PE рециркуляции машина для переработки пластика стиральная линия завод

Пластиковая бутылка для питья хлопья

отходы производства используется лома пластиковые бутылки ПЭТ хлопья дробления стиральная сушки линия по переработке техники

Новые поступления

Новинки товаров от производителей по оптовым ценам