Оборудование для обработки кварцевого песка включает в себя смеситель очистки конуса из нержавеющей стали

- Категория: >>>

- Поставщик: Jiangxi Well-Tech International Mining Equipment Co. Ltd.

Сохранить в закладки 1601283761711:

Описание и отзывы

Характеристики

Silica sand washing plant wash quartz sand trommel 1848 customization stainless steel screen and outlet groove ,drum,hopper all is stainless steel material,one customer buy 20line washing quartz sand/silica sand machine to Indonesia from JiangXi Well-tech International Mining Equipment Co.,Ltd have

delivery,include trommel screen,deslimining bucket,belt conveyor.

Thickner/desliming Cone

Hexagonal scrubber aigator with PP lining

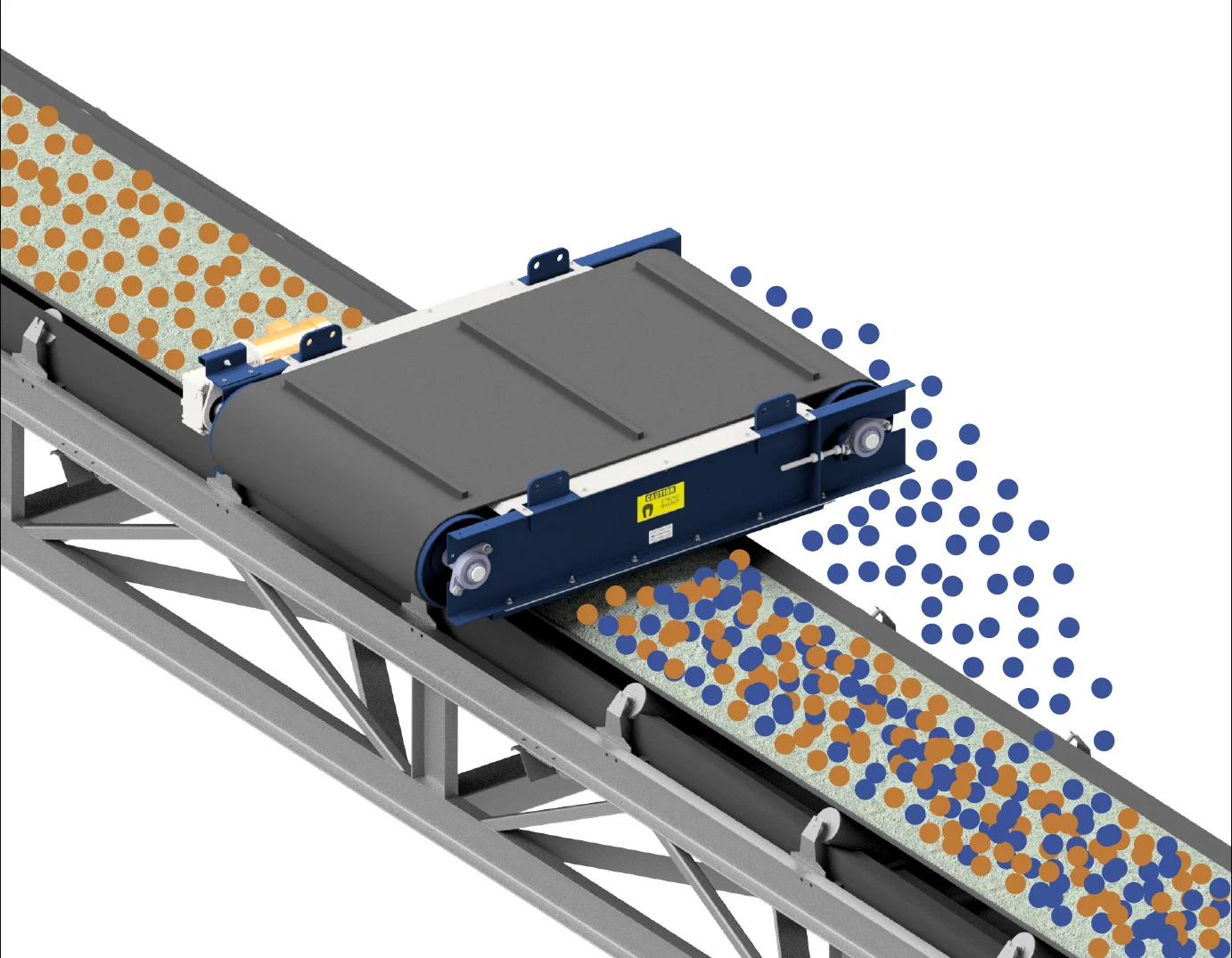

The Trommel screens provide a simple, efficient and economical solution to upgrade a wide rang of material and optimize the subsequent process steps of recovery. This method of screening helps to reduce operating and investment cost and to increase product quality, while allowing rapid and large volume processing. This material is then passed on to the downstream process equipment which can be in various forms such as centrifugal Concentrator, spiral chute, jig etc.

Our Trommel screens are constructed of high quality material, designed for high performance, high production rates, lower operating costs and lower maintenance.

Technical Specifications

Model | Capacity | Power | Drum diameter | Drum length | Screen size | Dimension | Weight |

GT1030 | 20-30 | 5.5 | 1000 | 3000 | 3-10 | 4800*1500*2165 | 3000 |

GT1230 | 50 | 7.5 | 1200 | 2500 | 4176*1506*2232 | 4200 | |

GT1530 | 80 | 11 | 1500 | 3000 | 5535*1860*2525 | 5100 | |

GT1545 | 80-100 | 15 | 1500 | 4500 | 7021*1860*2528 | 6000 | |

GT1848 | 150 | 22 | 1800 | 4800 | 7400*2150*3000 | 7500 | |

GT2055 | 200 | 30 | 2000 | 5500 | 8500*2500*3600 | 8600 |

Each model can process mobile style and fixed style, also can customization.

Small trommel screen

Mobile trommel screen

Working Principle

Material feeds into the drum, is lifted up by the rotation as it falls back down. This action is repeated with each revolution along the length of the drum. The finer material passes through the screen openings while the larger material tumbles towards its eventual exit at the rear of the drum.

Applicaiton:

Alluvial gold plant

Placer gold plant in Africa

Gold and diamond plant

Relate products:

Rotary scrubber

| trommel scrubber | jig machine |

Centrifugal concentrator | spiral concentrator |

shaking table |

FAQ:

FAQ:

Q;What’s the application of trommel screen?

A:Washing alluvial ore or screening gravel.

Q: Is your original ore sticky clay? Or only alluvial/placer sand?

1) If contain sticky clay ore, more than 30% or not?

2) Capacity?

3) -3mm materials percentage?

Q: Biggest capacity our trommel screen can process?

A: 200-300tph

Q: How big are the screen mesh size and how many layers?

A: Usually, our trommel is double layer, the inner screen mesh is 5mm, outer screen mesh is 10mm. But we can customizastion according to your requirements, we will use the Ø25mm diameter round steel to build the inner steel bar, outside screen material is high manganese woven net.

Q: If very small outer screen mesh size, will clogged?

A: We will add a steel brush onto the drum, so won’t be clogged at all. And we use the unique screen mesh design, result in longer screen life & no material clogging.

Q: Screen mesh material?

A: We use high manganese steel to build the screen mesh which is very durable.

Q: Can we change the screen mesh?

A: Yes, you can, usually we build the screen mesh to be active, so you can change the screen mesh size by yourself easliy on site.

Q: Driving mode?

A: Usually it’s electric motor, if you want, we can build it to be diesel engine for driving. Or build it to be diesel generator to provide power for it.

Q: If i need the complete mineral processing line. Can you help us build it?

A: Yes, we can help you combine a complete mineral processing line. and give you related professional advice as long as you need. There is a rich experienced engineers team of us, these 12 engineers always fly out of China to install, debugging our equipments on site and trainning the buyer’s staff.

Usually for alluvial ore, the flowchart is: Hopper---Trommel Screen---Vibrating Sluice/Jig/Gold Centrifugal Concentrator---Fixed Gold Sluice---Shaking Table For some other minerals, we can add magnetic separator, electric separator etc

Q: How long is the guarantee of your equipments? Does your company supply the spare parts?

A: The warranty period of is one year, if break during this guarantee period, we need to replace new one for you AT NO COST. And of course we will supply the spare parts for you for life-long time at lowest cost.

Q: Do you cut the steel plate by hand?

A: No, we use the plasma cutting machine to cut all materials which is controlled by computer. It’s very accurate.

--- PRE-SALE SERVICE

--- 1.Based on clients’ request and budget, our experts will strictly make efficient, reliable solutions accordingly;

2.Mine sample testing is available, we welcome the customer send the sample to us for testing by courier, or the customer take the sample to our factory for testing;

3. Design and provide the complete processing flowchart;

4. Design & manufacturer products according to clients’ demands.

--- AFTER-SALE SERVICE –

1.Pre-check and test the products before delivery;

2.Deliver the whole plant design for our clients which including infrastructure, electrical system and pipeline system design;

3.Trace the status of the shipping until the products received;

4.Prepare required documents to let clients pass custom clearance;

5.Dispatch experts to carry out below service on site:

6:Installation & debug of the machinery

7: Train the first-line operators & technical personnel

8:Carry out any other service clients may need

9:Provide technical exchanging & spare parts for life-long term

--- ONE STOP SOLUTION

-- 1.Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly;

2.Besides supply the flowchart design & equipment, we also provide the infrastructure design; Electrical & pipeline system design, etc. To help our clients complete the design of the whole plant;

3.After the installation, debugging of the equipment, the official production will also be guiding by our experienced engineers on site, to guarantee the output minerals perfectly meet your demands.

Why Choose Us?

We are manufacturer, not trade company.

-Quality: Guarantee

-Delivery: On Time

-Communication: In Time

-After-Sales Service: Excellent

-Engineer Team: Professional & more than 20 years experience on site

-Price: Competitive

Welcome you visit our factory when you are free, we will arrange our driver to pick you up from Airport for free and book hotel for you in advance. Well-Tech International Mining Equipment Co.,Ltd.

We are the biggest gravity separator machine manufacturer in China.we have 7 modem

workshops,1sample test workshop,1office build.

One office building and one ancillary building, factory environment is very good. We have tennis court, basketball court, table tennis course etc entertainment .

More details,please don’t hesitate to Contact us,you can send us inquiry as below,we will reply you within 24hours.

or add My Wechat: 18379873189 or WhatsApp:+86 18379873189,Thanks for your time!

Похожие товары

Заводская цена мини гравитационный сепаратор Вибрационный Золотой шейкер стол для горнодобывающей промышленности

Низкая цена шейкер Coltan высокий уровень восстановления Gemini Lab золотодобыча встряхивающий стол для танталита моназитной руды

Высокоэффективный циклонный порошковый сепаратор/порошковый сепаратор цена

Надежный и дешевый Золотой химический агент Jinchan повязка для золотой руды позолоченный моющий реагент обработки

Цена шаровой мельницы Antimony 2440 мм x 3660

Высокоинтенсивный сухой магнитный сепаратор высокоградиентный Магнитный барабанный цена

RCYD 600 мм 650 ширина автоматическая очистка Overband ленточный Магнитный конвейер постоянный магнитный Железный сепаратор

Новые поступления

Новинки товаров от производителей по оптовым ценам