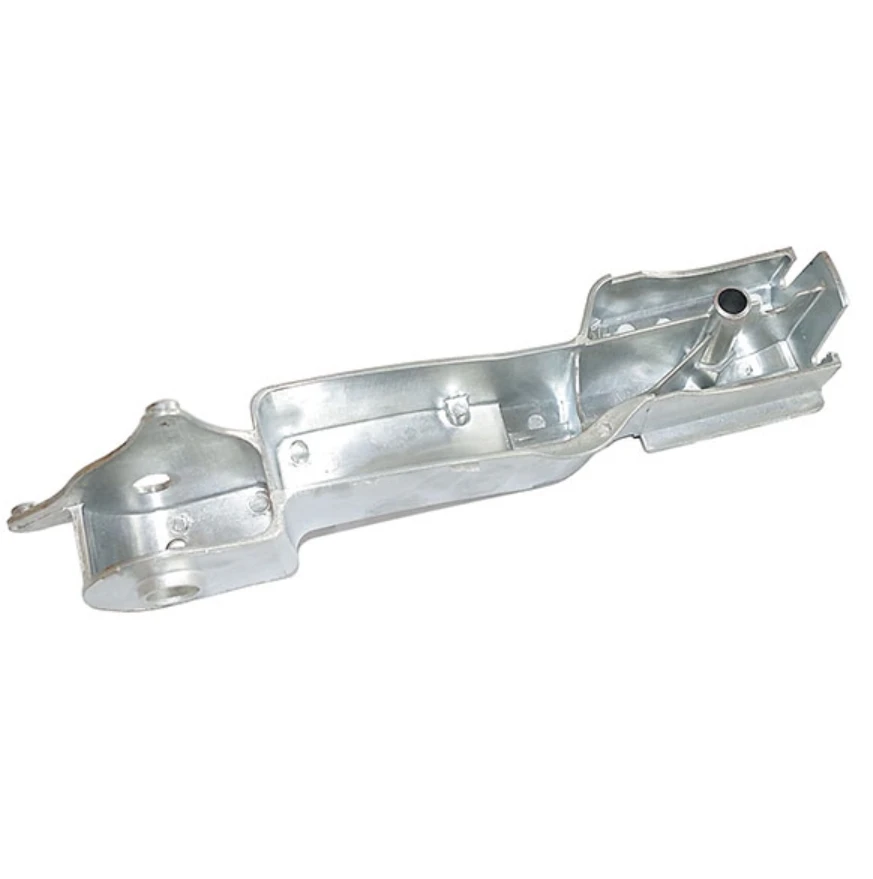

Высокоточная обработка CNC автозапчастей китайский завод двигатель с микропроводом EDM протяжная фрезерная сделанная стальным алюминием

- Категория: >>>

- Поставщик: Suzhou Jinyun Business Technology Co. Ltd.

Сохранить в закладки 1601283866810:

Описание и отзывы

Характеристики

3D view of factory size

Cooperation Objects

Customised SOP process

Provision of drawings

3D modelling

Modal flow analysis

Mould production

Die casting production

Product Quality Control

Customer Confirmation

Product Packaging

Logistic dispatch

Company Profile

Company Profile

The company specialises in aluminium alloy die-casting and precision machining for traditional automobiles, new energy automobiles, communications, photovoltaic energy storage, inverters, rail transportation, medical aviation and general industrial parts, the company's total asset scale has exceeded 1 billion yuan, covers an area of nearly 200,000 square metres, with 180,000 square metres of plant area, and is a high and new technology enterprise integrating R&D and production. The company has 150 ~ 4000 tons of fully automatic cold chamber die casting island production line 60, more than 600 advanced precision machining centres, and all kinds of supporting facilities and large-scale precision measuring instruments and equipment dozens of units, with an annual output of 50,000 tons of aluminium alloy die casting parts and components of the research and development, production and precision machining capabilities, to achieve the effect of large-scale production.

Introduction to 3D Process

3D modeling and mold flow analysis

The customer provides the drawings, and we have professional modeling engineers to conduct 3D modeling according to the drawings.

After the modeling is completed, mold flow analysis will be carried out to check whether there are any problems in the mold, and

mold production will be carried out after ensuring that the mold is correct

After the modeling is completed, mold flow analysis will be carried out to check whether there are any problems in the mold, and

mold production will be carried out after ensuring that the mold is correct

Wire cutting technology

It plays a crucial role in mold making, especially in the processing of high-precision and complex shape mold parts. Its main role is high-precision machining: wire cutting machine can provide extremely high processing accuracy, suitable for manufacturing

complex cavity, cutting edge and fine features of precision mold, such as punching mold, precision holes, irregular edges and so

on.

complex cavity, cutting edge and fine features of precision mold, such as punching mold, precision holes, irregular edges and so

on.

Electric discharge machining technology

Precision equipment for non-contact metal material processing using the principle of electrical discharge. Its main role is in the

mold manufacturing process, the mold steel or other difficult to process metal materials for fine molding processing, especially

for the complex shape, high hardness material cavity, hole, micro structure processing.

mold manufacturing process, the mold steel or other difficult to process metal materials for fine molding processing, especially

for the complex shape, high hardness material cavity, hole, micro structure processing.

Grinding machine

It is mainly used for high-precision grinding of the surface of the workpiece to achieve the required flatness, finish and

dimensional accuracy.

dimensional accuracy.

Vertical machining center

It provides efficient, high-precision and high-stability solutions for mold processing, and is an indispensable high-end

processing equipment in the mold manufacturing industry

processing equipment in the mold manufacturing industry

Mold workshop

After strict production process, the final completion of the mold manufacturing, and then the mold quality inspection, so that the

quality of the production of the mold is guaranteed

quality of the production of the mold is guaranteed

Die casting process

Raw material melting

Melting of aluminium alloys in a furnace.

4000T die-casting machine

4000T die casting for work

Die casting mould

Mould preparation in die casting machinery

Robotic arm extraction

Robotic Arm Extraction Products

Product Polishing

Worker master polishing products

Sandblasting machine

Sandblasting machine to carry out the work and integrate the product

Laboratory test

Laboratory testing of product quality, testing of product ingredients

Coordinate Inspection

Coordinate inspection of product dimensions

Infiltration equipment

Immersion equipment to test the airtightness of products

Airtightness water test

Airtightness water test to detect the airtightness of products

Airtightness air test

AirtightnessAirtightness testing detects the airtightness of products

Ultrasound cleaning

Ultrasonic cleaning of product surfaces to keep them clean

Our Advantages

1、Technical advantage | 1、Die casting industry experts more than 20 people,mold professional engineers more than 80 people; 2、3D design, mold flow analysis,mold manufacturing,die casting process analysis(customized service) |

2、Quality monitoring advantage | 1、More than 10 quality engineers,special quality control team; 2、The number of testing equipment 10; 3、Certification:ISO9001:2008 international quality certification systen;ISO14001:2004 system certification;ISO/TS16949:2002 Automotive industry quality system certification; |

3、Advantages of mold manufacturing | 1、Mold design engineer,can PRO-E,VG and other software; 2、Advanced equipment, HAAS machining center,gantry CNC,etc.,more than 49 equipments, an annual output of 300 sets of die casting mold; 3、We can design molds for customers(provide customized services) |

4、Die casting manufacturing advantages | 1、57 sets of production lines,with an annual capacity of 50000 tons of aluminum alloy die-casting parts; 2、Intelligent production level:automatic soup machine,automatic spray machine,automatic pick-up machine,automatic transmission belt,high pressure point cooling machine,cutting and shaping equipment; 3、Flexible product design,to provide production solutions,to provide conditions for small batch production |

5、Machine plus manufacturing advantage | 1、More than 600 sets of CNC machining machines and more than 60 sets of horizontal machining centers; 2、CNC machining programming engineers a total of 30 people,30 project engineering and technical personnel; |

6、Surface treatment technology advantages | 1、Independent spray plating supporting enterprises; 2、One hundred thousand dust-free spraying workshop,three spraying lines,twelve imported electrostatic spraying guns,four automatic plating production lines,two pre-treatment production lines; 3、Complete spraying and electroplating testing equipment; |

7、Supporting facility | 1、Clean workshop:1000 square meters GP12 clean workshop; 2、Product monitoring station; 3、Air tightness testing equipment; 4、Infiltration equipment; 5、Product automatic cleaning machine; |

Certifications

Похожие товары

Китай анодированный алюминий cnc обработка токарного станка запасные части

99,37 ₽ - 552,02 ₽

Многофункциональная силиконовая форма для вакуумного литья прототип деталей пластиковый корпус репликация

Быстрое прототипирование из нержавеющей стали оборудование для буровой машины детали автомашины алюминиевая Экструзионная труба

88,33 ₽ - 165,61 ₽

Китайский производитель изготовленный на заказ фрезерные станки с ЧПУ алюминиевые детали из нержавеющей стали медные латунные пластиковые

Болт в сборе ar cnc сплав изделия арматура аксессуары металлические детали

99,37 ₽ - 320,18 ₽

Высокоточные детали из нержавеющей стали KAIAO фрезерные станки с ЧПУ экономичное производство алюминиевых деталей решение для быстрой обработки прототипа

39,75 ₽ - 352,19 ₽

KAIAO латунные медные токарные станки с ЧПУ высокоточные Позолоченные прототипы производитель деталей

79,50 ₽ - 282,64 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $