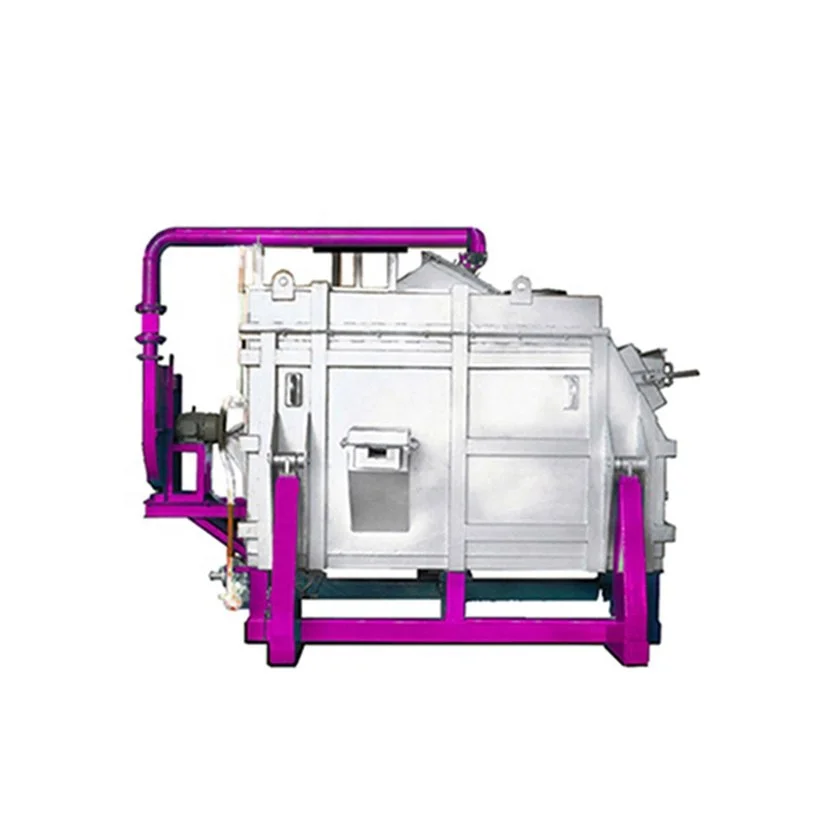

Высокотемпературная Микроволновая Печь вакуумная атмосфера печь для спекания микроволновой печи

- Категория: >>>

- Поставщик: Zhengzhou Hengtong Furnace Co. Ltd.

Сохранить в закладки 1601284055160:

Описание и отзывы

Характеристики

Our high-temperature microwave sintering furnace / microwave muffle oven / microwave ashing furnace is a new generation of high-temperature microwave standardized test workstation, with significant efficiency, energy saving, environmental protection, especially high-temperature microwave sintering furnace under air atmosphere for all kinds of various solid the calcined material, baking, sintering, high temperature synthesis, ash, melting and heat treatment study, the test sample can be used or produced in a constant temperature high temperature test or tests. Main features using a special high-performance industrial-grade microwave source to ensure continuous and stable long-running equipment; microwave sintering reaction sintering process spread evenly than conventional heating methods, can achieve ultra-fast heating (or program temperature control), and significantly shorten the holding time, the experimental efficiency multiplied; microwave output power can be adjusted to achieve precise temperature control curve; imported high-precision infrared thermometer, direct measurement of the sample temperature; equipped with an embedded microprocessor integrated temperature control system to achieve super-stable of temperature, a variety of unique special crucibles and insulation for selection of non-polluting materials; machinable handle a variety of microwave properties of different materials, versatility, flexibility and easy operation.

Features

The use of special high-performance industrial grade microwave source to ensure continuous and stable long-running equipment;

can achieve ultra-fast heating, and significantly shorten the holding time, the experimental efficiency multiplied;

microwave output power adjustable, timing, temperature control, and precise temperature control curve dynamic monitoring;

high-precision temperature infrared thermometer, direct measurement of the sample temperature, temperature stability: ± 1 ℃;

having an intake passage and outlet channels for communication inert gas experiments, the gas flow control;

a variety of unique special crucibles and insulation for selection of non-polluting materials;

machinability testing a variety of microwave processing characteristics of different materials, versatility;

Set exhaust passage corrosion can quickly exhaust gas generated during heating;

touch screen display and operation, equipped with the WINDOWS operating system, you can connect a PC;

can be set and stored in multiple temperature curve, the operating records are automatically stored, compatible printer;

Multiple security lock protection devices, door, heating chamber door is not closed or opened without starting microwave abnormal function;

safe and reliable microwave shielding design, multi-channel anti-leak protection, to achieve zero leakage microwave, to ensure the health and safety laboratory assistant

The main application areas:

Microwave atmosphere sintering furnace is a standardized multi-functional microwave high-temperature test workstation, which is suitable for synthesis, roasting, heat treatment, sintering and other process research under various atmosphere and vacuum conditions.

Powder metallurgy, magnetic hard, soft, metal magnetic, structural ceramics, varistors, thermistors, piezoelectric ceramics, microwave dielectric ceramic, honeycomb ceramic, porcelain, ceramics, carbon materials, catalysts, high-purity alumina, magnesium oxide, zinc oxide, zirconium oxide, aluminum hydroxide, zirconium hydroxide, and other non-metallic elemental experimental fine sintered products, all kinds of powder materials such as LED, three primary colors, long afterglow luminescent rare earth materials, battery materials (cobalt lithium, lithium manganese oxide, three elements, lithium iron phosphate, nickel hydroxide, etc.), all kinds of ceramic pigment, glaze, inorganic pigments, barium titanate, strontium, barium, strontium titanate, barium zirconate titanate , metal carbides, nitrides ferroalloys, diamond oxidation, reduction of the experimental technique of graphite exploration.

Parameter:

Model | YW01 | YW02 | YW03 | YW04 | YW05 |

The Highest Temp. | 1500℃ | 1500℃ | 1500℃ | 1500℃ | 1500℃ |

Digital random | ±1℃ | ±1℃ | ±1℃ | ±1℃ | ±1℃ |

Atmosphere system | standard:Air; optional:oxygen gas,nitrogen, helium and argon | ||||

Microwave power(KW) | 0~3000W (continued,adjustable) | 0~3000W (continued,adjustable) | 0~5000W (continued,adjustable) | 0~8000W (continued,adjustable) | 0~15000W (continued,adjustable) |

Temperature range | 400~1600℃ | 400~1600℃ | 400~1600℃ | 400~1600℃ | 400~1600℃ |

Thermometry way | infrared thermometer | ||||

Control method | PLC | PLC | PLC | PLC | PLC |

Magnetron cooling way | Air cooling | Air cooling | Water cooling | Water cooling | Water cooling |

Floor space(sq.m.) | 0.8m2 | 0.8m2 | 1.2m2 | 1.5m2 | 3.0m2 |

We can supply you the translation methods whatever you want.

--By express (DHL/Fedex/etc.)

--By Sea to your nearest Seaport

--By Air to your nearest Airport

--By the sellers’ shipping agent

Package details: standard export case or plywood case or plywood case hanging bracket, or according to requirements

1. Your inquiry related to our products or prices will be replied within 24hours.

2. Offering the support to solve the problem in the application or selling period.

3. Customized design.

Zhengzhou Hengtong Furnace Co., Ltd is a high-tech enterprise that focusing on Si3N4 Silicon Nitride ceramic thermocouple protection tube for liquire aluminium. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. it has advanced technology and prodcution line. Hengtong’s products are widely used in high-temperature kilns such as non-ferrous metals, steel, building materials and construction, chemical, electric power, waste incineration, and hazardous waste treatment. Based on the strict adherence to ISO9001-2008 or Industry Standard or other International Standard, our products have been approved and accepted by clients and users from New Zealand,South Korea, India, Russia, Italy, United Kingdom, USA, the Philippines and etc. We will provide you with high quality products, overall services and reasonable price.

What your need is what we are striving for !

1.Are you a manufacturer or a trader?

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

2.What is your delivery time?

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

3.How can you get quotation?

Please kindly send me your drawing with technical requirement and demand quantity. If you don't have the drawing,please kindly courier samples to us.We will quote our best price as soon as possible.

4.Do you accept customized production based our specification?

Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

Похожие товары

Горячая OEM продажа автоматический углеродного волокна спекания вакуум атмосфера графитизация печь

для переработки металлолома индукционная плавильная печь многоцелевого назначения

Оборудование для переработки драгоценных металлов индукционная печь обработки нагрева

250 кг 500 промышленный Среднечастотный металлолом индукционная плавильная печь сталь медь алюминий машина электрическая

Без пыли загрязнения HF Металла термической обработки Индукционное машина

1 кг 3 5 маленькая золотая индукционная плавильная печь мини-плавильная машина для плавки драгоценного металла серебра титана платины

Новое состояние 1 тонна автоматическая гидравлическая печь для переработки лома алюминия экономичная промышленная на масле

Новые поступления

Новинки товаров от производителей по оптовым ценам