API 6A Буровая головка скважины двойной фланец и адаптер Шипованный DSA для устья

- Категория: >>>

- Поставщик: Dongying Link Petroleum Equipment Co. Ltd.Dongying Ltd.

Сохранить в закладки 1601284202927:

Описание и отзывы

Характеристики

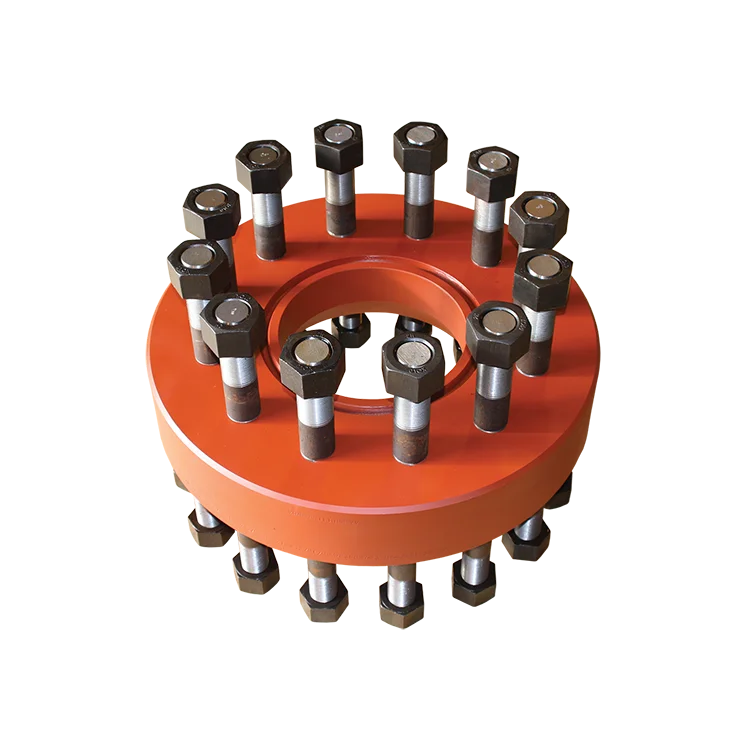

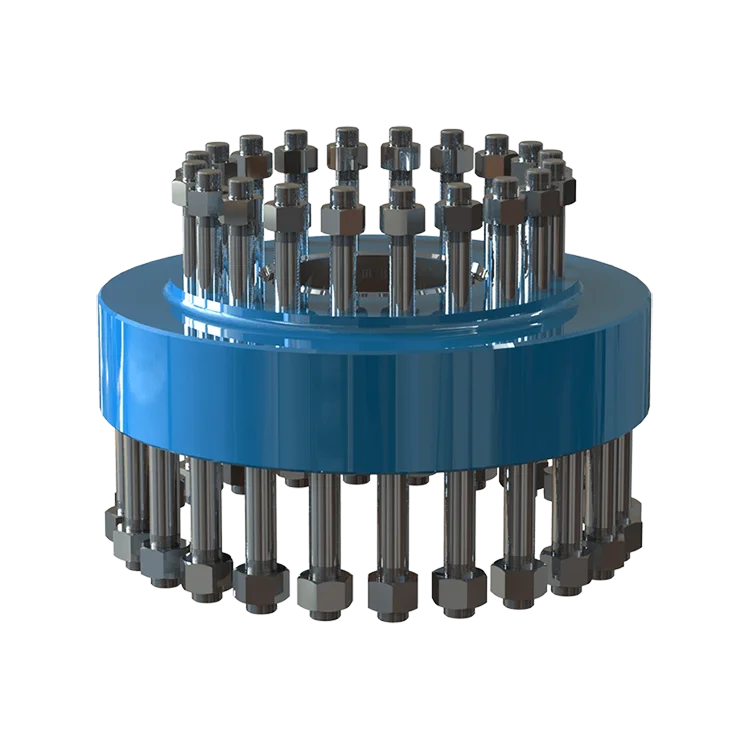

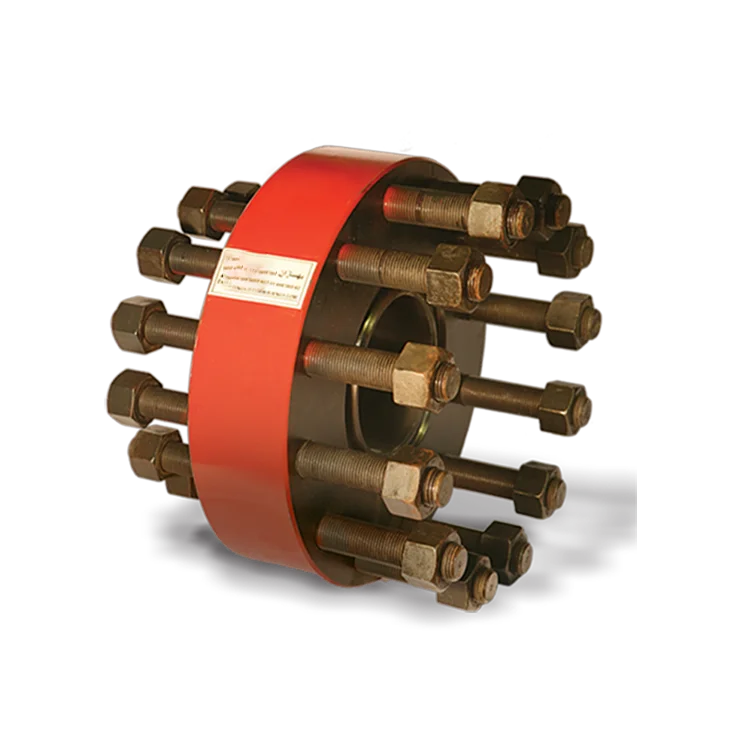

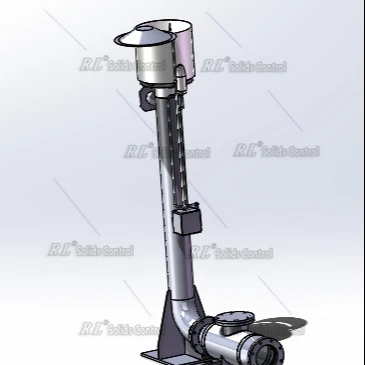

API 6A drilling wellhead double flange and adapter double studded adapter DSA flange for wellhead

Double Studded Adapter Flange (DSAF) or Double Studded Adapter (DSA) is a flange with a through bore and a ring groove on each side, drilled and tapped bolt hole sets on both sides and tapped end studs complete with nuts fitted on both sides. Unlike a spacer, the two sides are usually different in size and/or pressure rating. Double studded adapter flanges are commonly utilised to connect and adapt flanges with different nominal sizes, pressure ratings, and configurations.

All of our double studded adapter flanges(DSAF) are fully designed, manufactured, and tested according to API 6A and NACE MR0175 standards. The standard material is high quality integral forged AISI4130 alloy. Available in sizes from 1-13/16" to 30" and working pressure up to 15000PSI. For sour service, all ring grooves can be inlaid with stainless steel SS316 or inconel 625 for better protection. The studs and nuts are available with Zinc Coated, Cadmium Coated, or Xylan Coated. Other sizes, material, and pressure ratings are also available upon request. Aside from API6A double studded adapter flanges(DSAF), we also produce and supply other types API 6A flanges, such as threaded flanges, spacer spool flanges, blind flanges, companion flanges, target flanges, test flanges, and adapter spools for all client needs.

Double studded adapter flange is a combination of flanges of different sizes and pressure ratings.

Sanmon supplies ideal DSA for reliable and consistent performance on their production system. Our adapter flanges are in various sizes and pressure ratings as per customer's specified thickness, consistent with design considerations. It is the important device to connection the different flange for wellhead, so the material of the body and studs and nuts shall be conforms the related requirements. The size is in accordance with API 16A flange certification.

Manufactured according to ISO10423/API-6A,ASME B16.5 PSL-2,PR-1,DD, L-U

(1) OEM and custom-made service.

(2) Full machining, primer painting, and surface treatment.

(3) Full material testing process.

(4)Machinery properties and Chemical components testing after raw casting

(5) Hardness checking after heat treatment

(6) Dimensions testing after machining

(7) Quality and production control checks though all the following flow:

Drawings→ mould making →raw casting → sandblasting →rough machining or finish machining →surface treatment →product check→ packing →delivery strict

| Type | Size | Working Pressure |

| Blind Flange | 1-13/16” to 21-1/4” | 2,000 psi, 3,000 psi, 5,000 psi, 10,000 psi, 15,000 psi, 20,000 psi |

| Target Flange | 1-13/16” to 21-1/4” | 2,000 psi, 3,000 psi, 5,000 psi, 10,000 psi, 15,000 psi, 20,000 psi |

| Testing Flange | 1-13/16” to 21-1/4” | 2,000 psi, 3,000 psi, 5,000 psi, 10,000 psi, 15,000 psi, 20,000 psi |

| Weld Neck Flange | 1-13/16” to 21-1/4” | 2,000 psi, 3,000 psi, 5,000 psi, 10,000 psi, 15,000 psi, 20,000 psi |

| Product Name | Double studded adapter ,API 6A flange(DSA),Threaded flange adapter |

| Standard | ASTM,AISI,DIN,EN,AS. |

| Production Process | Forging, Heat Treatment, CNC Machining. |

| Machining Range | Outer Diameter Max 3000mm, Length Max 12000mm. |

| Production Precision | Tolerance:0.01mm,Roughness:Ra0.4,Concentricity:0.01mm,Roundness:0.005mm. |

| Provide Product Certificate | PED4.3 AD2000,EN10204-3.1(Certificate No.:DGR-0036-QS-W 728/2015/MUC).APIQ1 |

| Material | Carbon steel,Stainless Steel,Duplex Stainless Steel,Copper,Clad Material.Alloy steel |

Product Picture

The products are packed in sturdy plywood cases. All movable parts are secured to minimize movement during transit. Each crate is labeled with clear shipping instructions and necessary warning labels, complying with international transportation safety standards.

Dongying LINK Petroleum Equipment Co.Ltd, is a professional equipment manufacturer , sales and service provider focusing on the oil and gas industry.

We provide many types of drilling equipment, as well as corresponding accessories and services,including cementing and drilling tools, handing tools, mud pump parts, valves, solid control and well control equipment, etc. All products are certified to international standards API, ensuring reliability and safety under extreme conditions.

We try our best to provide high-quality, high-performance petroleum equipment, and we are very glad to establish a long-term business relationship with you. If you are interested in any of our products, please feel free to contact us for more information.

Q1. How to get an accurate quotation?

A1: You should offer concrete technical requirements, drawings, pictures and so on, then our engineers will provide solutions and quotations in time.

Q2. How about your MOQ?

A2: Min order quantity is different depending on your quantity.

Q3. How about your delivery time?

A3: The specific delivery time depends on the items and the quantity of your order. And also our price is based on products and order quantity.

Q4. How about the Payment terms?

A4: Generally, T/T, 30% deposit in advance +70% balance before shipment.

Q5: How about your after-sales service?

A5:As a manufacturer, we accept goods return or replace for quality problem. Backup skillful and experienced sales team would help you get an efficient solution.

Похожие товары

China supplier 8 1/2 inch Oil Rig Steel Tooth Tricone Drill Bit

Tubing Anchor Down Hole Tools

Valve Seat and Ball for Sucker Rod Pump

ZG 0 ~ 20000 фунтов на квадратный дюйм 4:1 манометры система дебустеров для гидроразрыва пласта и цементовозов

Высококачественное устройство для зажигания Факельного газа на нефтяных месторождении/сжигание твердого раствора

API 5CT нефтяной нюе нить труб

API 11B Polished Rod Spraying Metal

Новые поступления

Новинки товаров от производителей по оптовым ценам