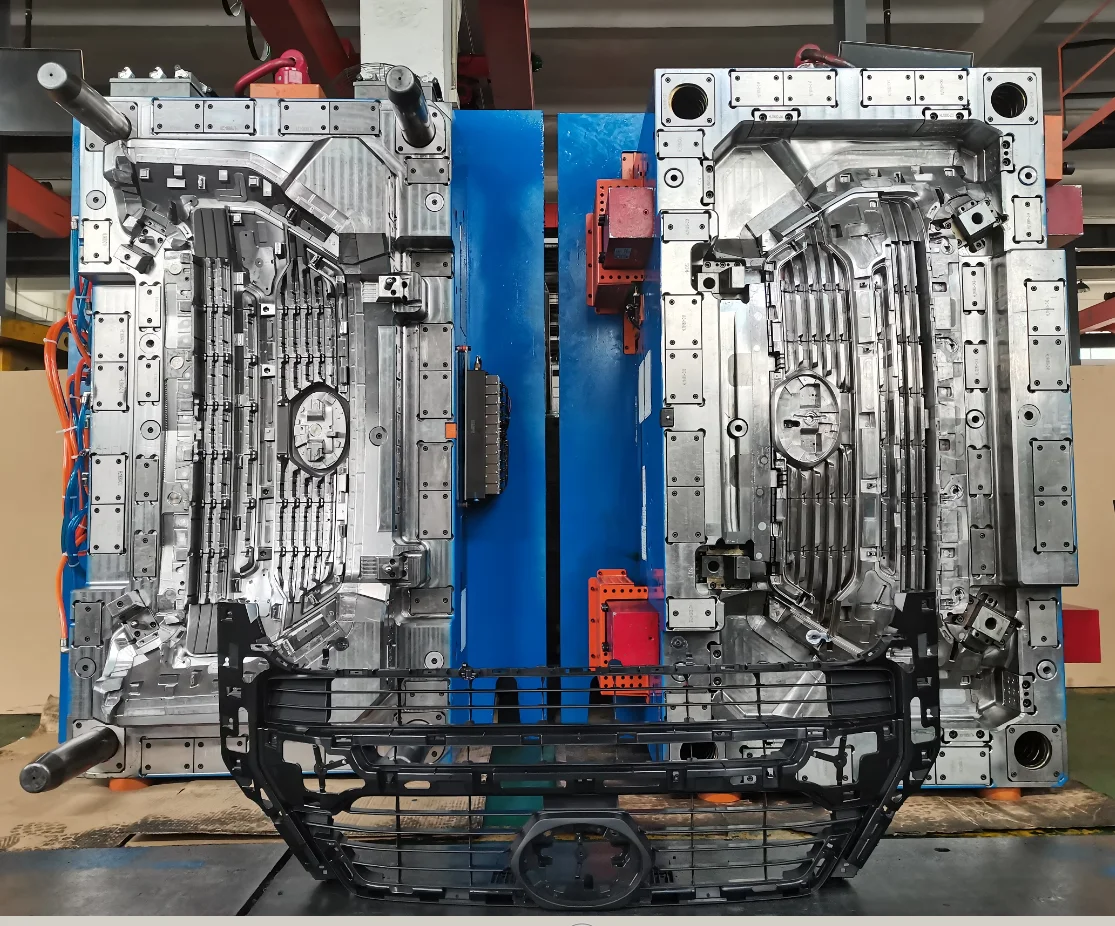

Передняя решетка автомобильных деталей подходит для таких как Mercedes Benz Honda Toyota BYD пластиковые формы

- Категория: >>>

- Поставщик: Shenzhen Yida Intelligent Technology Co. Ltd.Shenzhen Ltd.

Сохранить в закладки 1601284452814:

Описание и отзывы

Характеристики

3D Printing Services

3D printing (additive manufacturing technology) is an advanced manufacturing technology that uses layered material accumulation to

create three-dimensional models, parts, and components. Compared to traditional manufacturing methods, 3D printing technology has

the advantages of eliminating the need for molds, a variety of material choices, high customization, and flexibility.

create three-dimensional models, parts, and components. Compared to traditional manufacturing methods, 3D printing technology has

the advantages of eliminating the need for molds, a variety of material choices, high customization, and flexibility.

Application areas of 3D Printing

1. Manufacturing: 3D printing can be used for rapid prototyping or small-batch production, with a more efficient and

cost-effective production mode, which helps speed up the product's time-to-market.

2. Aerospace: 3D printing technology has long been used in the manufacture of aircraft engines and other parts. Printing using

high-strength, lightweight materials can greatly reduce the weight of aircraft, improve speed, and efficiency.

cost-effective production mode, which helps speed up the product's time-to-market.

2. Aerospace: 3D printing technology has long been used in the manufacture of aircraft engines and other parts. Printing using

high-strength, lightweight materials can greatly reduce the weight of aircraft, improve speed, and efficiency.

3. Medical:

3D printing can be used in the manufacture of medical devices, human simulation models, and artificial organs,

especially in personalized medicine, which can provide doctors with better treatment plans.

especially in personalized medicine, which can provide doctors with better treatment plans.

4. Construction:

3D printing technology can be used to construct complex structures that are beyond human labor, such as

stairs,radiators, or walls.

stairs,radiators, or walls.

5. Customized Consumer Goods:

3D printing can be used to produce personalized consumer goods such as jewelry, shoes, phone cases,etc., with higher levels of

customization and more distinctive features compared to traditional retail models.

customization and more distinctive features compared to traditional retail models.

Metal Materials | steel, aluminum, titanium, nickel and other metallic materials,aluminum powder, magnesium powder, titanium powder, tungsten powd |

Ceramic Materials | typically comprised of alumina, zirconia, etcused to manufacture high-temperature and chemically resistant components,. |

Thermoplastic Materials | ABS, PLA, PC, PA, POM, etc. They are used to manufacture prototypes, personalized consumer goods, plastic gears, and components. |

CNC Machining Services

YIDA CNC machining prototype service is a subtractive manufacturing process, where plastic raw material is removed with a variety of precision cutting tools to make a part or product. Advanced software is used to control the equipment according to the specification of your 3D product design. Our professional team of engineers and machinists program the equipment to optimize cutting time, surface finish,and final tolerance to meet your design specifications. we Have big CNC machine can meet requirement of very big part like Auto bumper, robert, medical equipment etc.

Silicone replication

Silicone replication (also known as vacuum replication) refers to the use of an existing template to create a mold in a vacuum state

Produce a silicone mold and pour it in a vacuum state using materials such as PU, silicone, nylon ABS, etc,

Thus, a replica identical to the original sample was cloned, with a reduction rate of 99.8%. Silicone mold has a long service life

About 15-25 times. Suitable for small batch customization. Low production cost, no mold opening, short production cycle.

Produce a silicone mold and pour it in a vacuum state using materials such as PU, silicone, nylon ABS, etc,

Thus, a replica identical to the original sample was cloned, with a reduction rate of 99.8%. Silicone mold has a long service life

About 15-25 times. Suitable for small batch customization. Low production cost, no mold opening, short production cycle.

Advantage:

1、Low production cost. The processing cost is also much lower than CNC machining and 3D printing;

2、Short production cycle. Save time on mold opening and greatly improve production efficiency;

3、No mold opening required. Save time on mold development, win valuable time for customer research and development of new products, and seize the market

Standby mode;

4、High degree of restoration, low probability of processing failure;

5、Suitable for small batch production, with short customization time and low cost;

6、Exquisite and meticulous workmanship, without burrs

2、Short production cycle. Save time on mold opening and greatly improve production efficiency;

3、No mold opening required. Save time on mold development, win valuable time for customer research and development of new products, and seize the market

Standby mode;

4、High degree of restoration, low probability of processing failure;

5、Suitable for small batch production, with short customization time and low cost;

6、Exquisite and meticulous workmanship, without burrs

Shenzhen YIDA Intelligent Technology Co.Ltd.

Shenzhen YiDa mold engineering company was founded in 2015 and is located in Shenzhen, Guangdong province. As a professional tooling ,injection molding and injection service supplier,

YIDA MOLD has excellent and highly skilled teams who focus on product development & design, prototype, quality control & inspection and have special strong technology on complicated and super large mold ,big stack mold, high precision mold ,Two-color mold, rapid tooling, High volume mold and production service .and strong advantage for super longer slide core mold, we have Unique techniques to solve very big mold plate deformation problem. We design and make very good cooling line to short injection circle time .Our products export to USA , Israel, Europe , Japan etc.

YIDA MOLD has excellent and highly skilled teams who focus on product development & design, prototype, quality control & inspection and have special strong technology on complicated and super large mold ,big stack mold, high precision mold ,Two-color mold, rapid tooling, High volume mold and production service .and strong advantage for super longer slide core mold, we have Unique techniques to solve very big mold plate deformation problem. We design and make very good cooling line to short injection circle time .Our products export to USA , Israel, Europe , Japan etc.

YIDA did many projects on Automotive mold, outdoor furniture mold, household mold, big tool box mold, medical equipment mold , Agriculture mold , transparent part, electronic and electrical products . To supply the satisfactory products and services.

YIDA MOLD have built a modern quality management system which is in strict accordance with international standards, We Adhering to the "professional , Integrity, serious, Strict work to meet Customer needs“ for the value. We can speak English very well and can realize online technical meeting, online witness mold test and quality checking .

Please Tell us your idea ,Our comprehensive services will help you save cost , cut down on time to market. We are sincerely looking forward to work with you .

FAQ

1. Could i have prices of your products?

Welcome . Please feel free to send us an email here. You will get our reply in 24 hours

3:How big test injection you have?

From 80T to 3500T

4:Which kind of mold you can do?

have special strong technology on complicated and super large mold ,big stack mold, high precision mold ,Two-color mold, rapidtooling, High volume mold and production service .and strong advantage for super longer slide core mold, we have Unique techniques to solve very big mold plate deformation problem..

5: Usual which steel you use for?

Usual we use import: SCHMOLZ + BICKENBACH , FINKL,Groditz,ASSAB,P20,1.2738, 738H,738HH,2510,2344,LKM mold base.

6:Usual which hot runner you use for?

INCOE,YUDO,HRS,MOLD MASTER.

7:Usual which desian STD you use for?

HASCO.DME.CUMSA.MISUMl,meusburger.

8. What's the lead time for regular order?

Depend mold size,Usual 20days-100days,

9:How you support project?

We will help you check mold design,check steel,every week wil send you process report,make mold test report.before moldshipping will make checking report,After finish all will send you all mold data.

11.Can l get a discount?

Yes, please contact us to get the best price

2.How big mold you can made it?

From a few hundred KG to 45Ton .

From a few hundred KG to 45Ton .

3:How big test injection you have?

From 80T to 3500T

4:Which kind of mold you can do?

have special strong technology on complicated and super large mold ,big stack mold, high precision mold ,Two-color mold, rapidtooling, High volume mold and production service .and strong advantage for super longer slide core mold, we have Unique techniques to solve very big mold plate deformation problem..

5: Usual which steel you use for?

Usual we use import: SCHMOLZ + BICKENBACH , FINKL,Groditz,ASSAB,P20,1.2738, 738H,738HH,2510,2344,LKM mold base.

6:Usual which hot runner you use for?

INCOE,YUDO,HRS,MOLD MASTER.

7:Usual which desian STD you use for?

HASCO.DME.CUMSA.MISUMl,meusburger.

8. What's the lead time for regular order?

Depend mold size,Usual 20days-100days,

9:How you support project?

We will help you check mold design,check steel,every week wil send you process report,make mold test report.before moldshipping will make checking report,After finish all will send you all mold data.

10.Do you inspect the finished products?

Yes, each step of production and finished products will be came out inspection by QC department before shipping

11.Can l get a discount?

Yes, please contact us to get the best price

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Похожие товары

Пластиковая форма для детской ванны

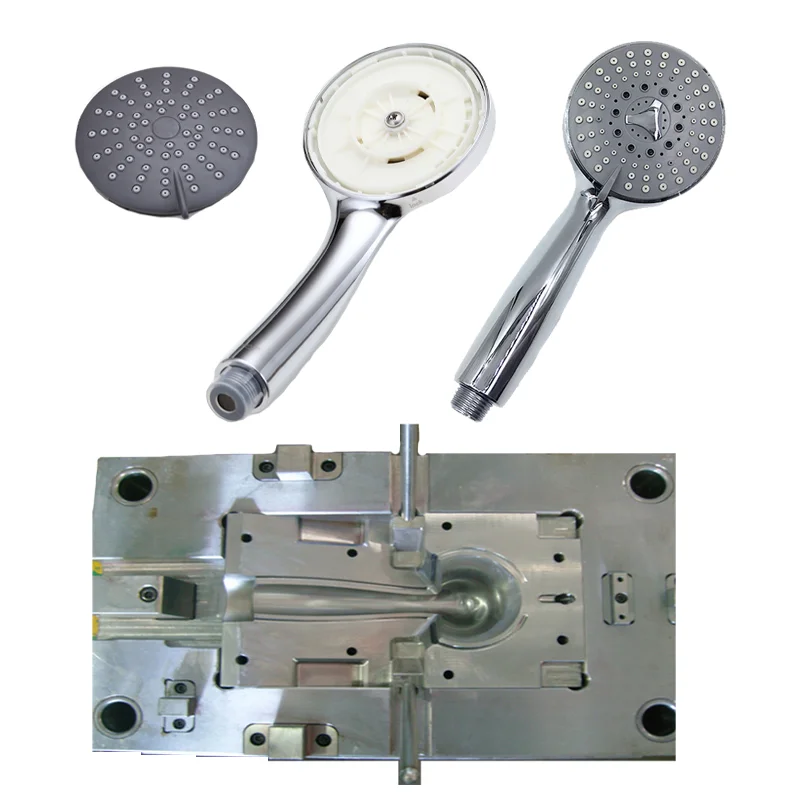

Индивидуальная пластиковая круглая душевая головка из АБС-пластика литье под давлением для домашнего использования изготовленная стального материала

P & M ABS пластиковая форма для душа

1 000,00-4 000,00 $

Декоративная бетонная балясина

18,00-25,00 $

Пластиковая форма для детской ванны

Высококачественная пластиковая пресс-форма для душевой лейки таможенное обслуживание

3,30-5,00 $

Горячая Распродажа Высококачественная пластиковая детская ванна раковина для душа

1 800,00-2 000,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $