Хорошее качество песка сушки производственной линии кварцевый песок сушилка завод

- Категория: >>>

- Поставщик: Henan Kolev Equipment Technology Co. Ltd

Сохранить в закладки 1601284473986:

Описание и отзывы

Характеристики

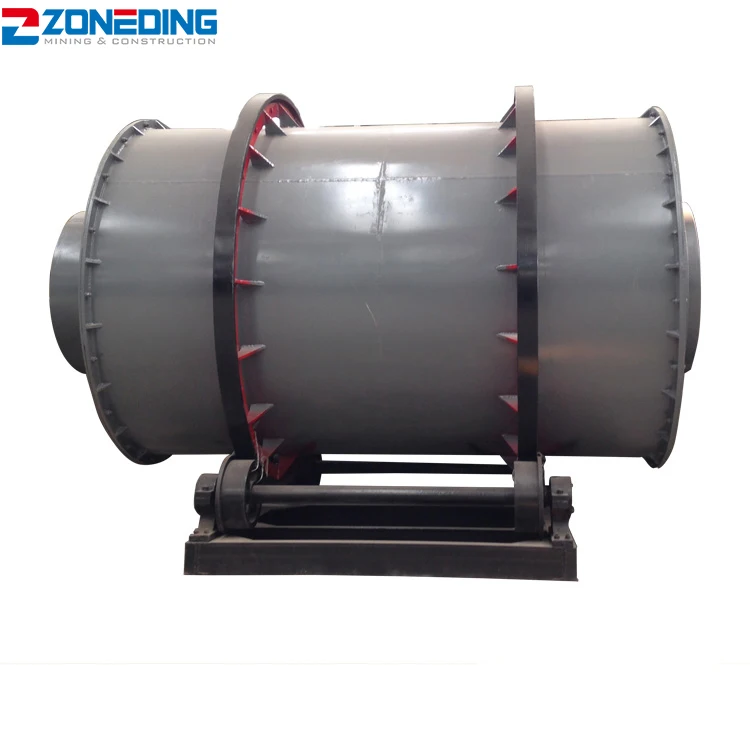

Good Quality Sand Drying Production Line Quartz Silica Sand Dryer Plant

Sand dryer is also known as the three pass drum dryer, three return cylinder dryer, on the basis of the single-cylinder dryer, developed and manufactured.

And precisely monitor and control the materials temperature and effectively take advantage of heat.

Sand Dryer Line Process

1.The wet materials are first evenly sent to the belt conveyor through the feeder, and then enter the dryer through the conveyor belt.

2.The heat generated by the fuel combustion in the hot blast furnace enters the main machine under the action of the exhaust fan and comes into contact with the materials, completing heat transfer and quickly evaporating water.

3.The three-cylinder dryer has a three-pass sealed structure, which can reduce heat loss and improve thermal efficiency. The dried material is transported to the linear vibrating screen for screening, and then sent by the elevator to the storage tank for storage or packaging.

4.The upper part of the hopper is used to discharge dust and other materials during the process. After being processed by the dust removal system, environmental protection can be achieved.

4.The upper part of the hopper is used to discharge dust and other materials during the process. After being processed by the dust removal system, environmental protection can be achieved.

Model(m) | Capacity(t/h) | Final moisture(%) | Drying Temperature(℃) | Powder(kw) |

KLF-TH1630 | 1-3 | <5 | 700-800 | 3 |

KLF-TH2240 | 5-8 | <5 | 700-800 | 4 |

KLF-TH2460 | 8-12 | <5 | 700-800 | 7.5 |

KLF-TH2660 | 15-20 | <5 | 700-800 | 15 |

KLF-TH2870 | 25-30 | <5 | 700-800 | 18.5 |

KLF-3080 | 30-40 | <5 | 700-800 | 22 |

Q1 | Are you factory or trade company? |

A1 | We are factory with CE. We have factory in China. |

Q2 | Where your products have been exported before? |

A2 | Our products have been sold to South Asia, Africa, South America, middle East and so on. |

Q3 | How will you help the customer to install the equipment? |

A3 | Our senior engineer will supply installation and training service on-line or on-site. |

Q4 | How about the wear parts supply? |

A4 | We will supply the wear parts with factory price . You can buy them from our factory in China. |

Q5 | What about after-sale service? |

A5 | 12 months warranty for all kinds of products. |

Q6 | How to get the free solution and quotation? |

A6 | Please send inquiry to us ,leave your whaspp and email , our sales manager will contact you within 1 hours. |

Похожие товары

Заводская прямая продажа роторной сушилки для мокрого песка

2 196 364,50 ₽

Китайский поставщик трехцилиндровая роторная сушилка для речного песка цена

2 196 364,50 ₽

Промышленная электрическая нагревательная машина для обезвоживания рисовой шелухи Роторная сушилка зерна производственная линия

105 381,13 ₽ - 278 428,03 ₽

Промышленная роторная сушилка для сушки влажного песка

2 196 364,50 ₽

2-3Tph кремнеземный песок речной линия по сушке шлаковой Руды Роторная сушилка для угля цена

942 883,75 ₽ - 953 976,50 ₽

Лидер продаж конусная Вакуумная сушилка серии szg вращающаяся конусн

1 109 275,00 ₽

Высококачественная 2024 сушильная машина для зерна сушилка риса пшеницы сухих башен цены

1 617 983,43 ₽ - 3 302 007,00 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $