Taizhou Jingxin Trade Ltd Tornado Аксессуары для мотоцикла Xiamen Yuanduoduo Trading Co Xian Function Material Group Cnc

- Категория: >>>

- Поставщик: Chengdu Machining Technology Co. LtdChengdu Ltd

Сохранить в закладки 1601285255993:

Описание и отзывы

Характеристики

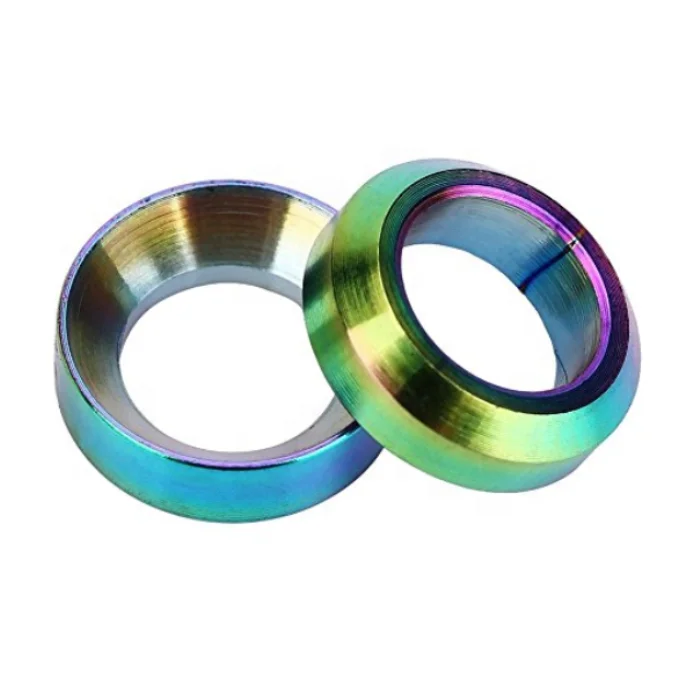

| Aluminium Washer Aluminum gaskets are characterized by low price and variety of colors, which can be used in the modification industry such as automobiles and motorcycles to beautify their appearance, while also having the ability to reduce friction, prevent leaks, isolate, and prevent loose or dispersed pressure |

Spring Washer Spring washers are widely used in load-bearing and non-load-bearing structures of general mechanical products, which is characterized by low cost, easy installation, and suitable for frequent installation and disassembly parts. Its material is stainless steel and carbon steel, the spring washer can play a looser, increase the function of pre-tightening force, and the flat washer does not have this function, it can be used to increase the fastening contact area, prevent the friction between the bolt and the workpiece, protect the surface of the connector to prevent the bolt nut from scratching the surface of the workpiece |  |

| Flat Washer Flat washers are typically thin pieces of various shapes that are used to reduce friction, prevent leaks, isolate, and prevent loosening or dispersing pressure. These components are found in many materials and structures and are used to perform a variety of similar functions. Due to the material and process limitations of threaded fasteners, the supporting surface of bolts and other fasteners is not large, so in order to reduce the compressive stress of the bearing surface, the surface of the connected part is protected |

Lock Washer Lock washer is used to lock screws and prevent loosening. Because it is different from the structure of ordinary washers, friction can be used to achieve the effect of anti-loosening. The external tooth lock washer uses the convex tooth shape to contact with the connected surface, and bites the connected surface under the pre-tightening force of the nut. The internal tooth lock washer uses the inward tooth shape to give the nut a force, which increases the friction between the nut and the bolt, so as to play the effect of locking and preventing loosening. |  |

Certificate

Our Equipment

Testing Equipment

Contact Us

Upload your drawings to get an instant online fabrication quote on custom-metal prototypes and production parts.

Factory Show

|  |  |

| Laser Engraving | Laser Cutting | Drilling |

|  |  |

| Pressing Rivet | Oil Hydraulic Press | Bending |

Customer Reviews

1. How can we ensure our product quality?

2, Inspect all the materials when arrived, ensure they will be catch up customers' requirements.

3, Inspect the semi-finished goods.

4, Inspect the finished products.

5, Final inspection when packing up all the goods. if there are not any problems for this step, our QC will issue the inspection report and release these products.

2. How about your productivity?

A: We have factories in China, Chengdu, Chongqing, and Shenzhen,which are strong enough to guarantee our customers' quality andtimeliness.

3. What are the terms of payment?

A: Payment terms: Paypal, Western Union, Offshore Account or as your requirement. Payment terms are flexible for us in accordance with specific conditions. Generally, we advise a 30% TT deposit, balance is paid before shipment.

4. What will you do after-sales ?

A: When our metal parts apply to your products, we will follow up and await your feedback. Any question related to our metal parts, our experienced engineers are ready to help

Похожие товары

Высококачественная шайба с тонкой прокладкой из пружинной стали din 988 диаметром 10-40

Заводская цена Заказная пружинная шайба со звездообразным замком стальная Замковая звездами

Заказной класс 5 М6 титановый Вогнутый выпуклый балансир тормозной винтовой шайба прокладка для горного велосипеда

Хит продаж TC-1025 медная шайба ассортимент

Горячая продажа пружинный замок шайба профессионального производства M6-M48 DIN127 пружинная шайба

Титановые круглые стопоры DIN 472 для вала

500 шт. фиксаторы для отверстия штифта кольцо-фиксатор подшипника фиксаторное кольцо 65 3-12

Новые поступления

Новинки товаров от производителей по оптовым ценам