Крытый украсить ПВХ потолочные панели машина доска делая машину производственная линия оборудование

- Категория: >>>

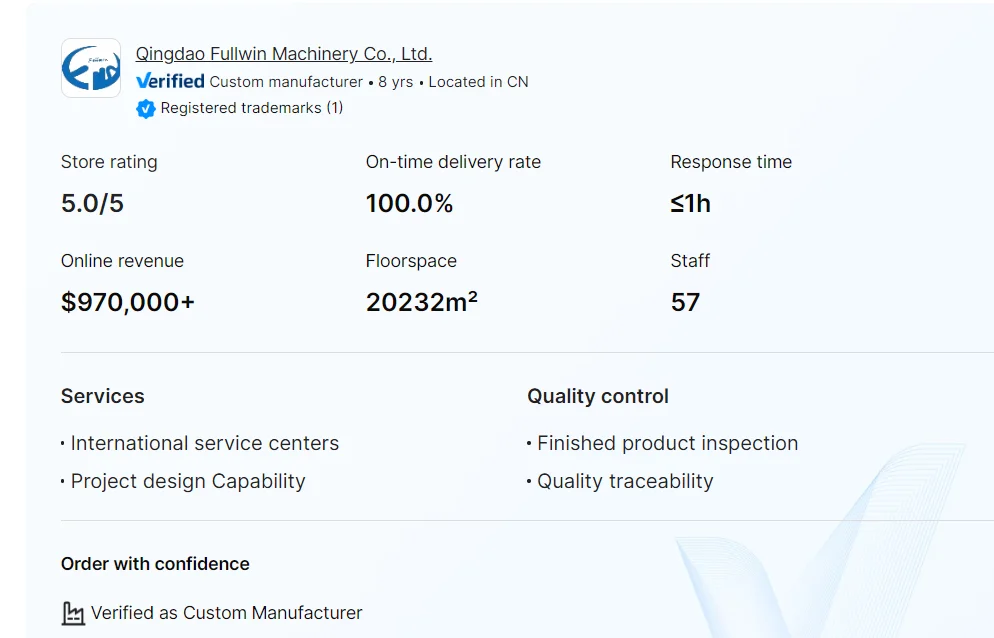

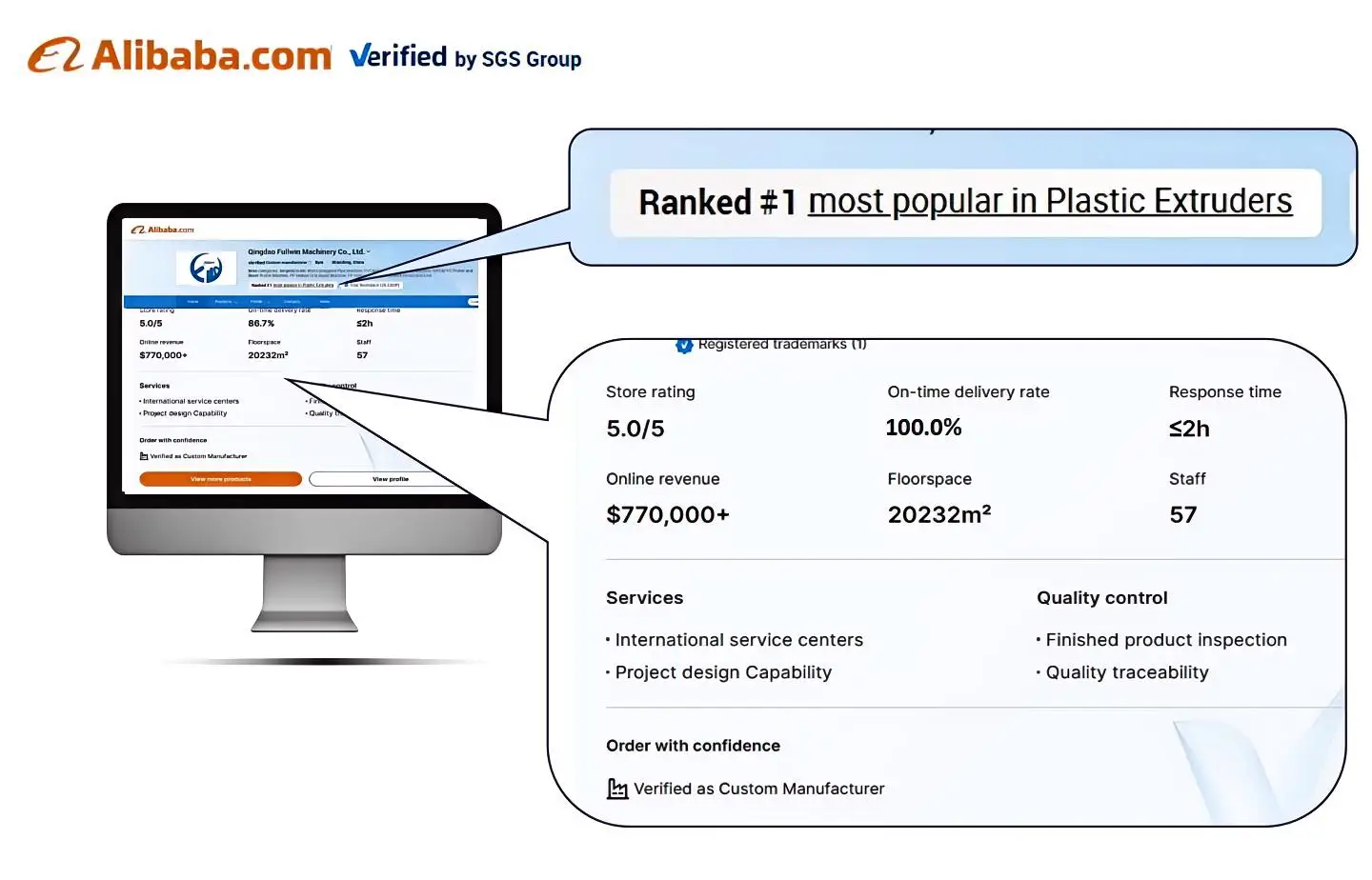

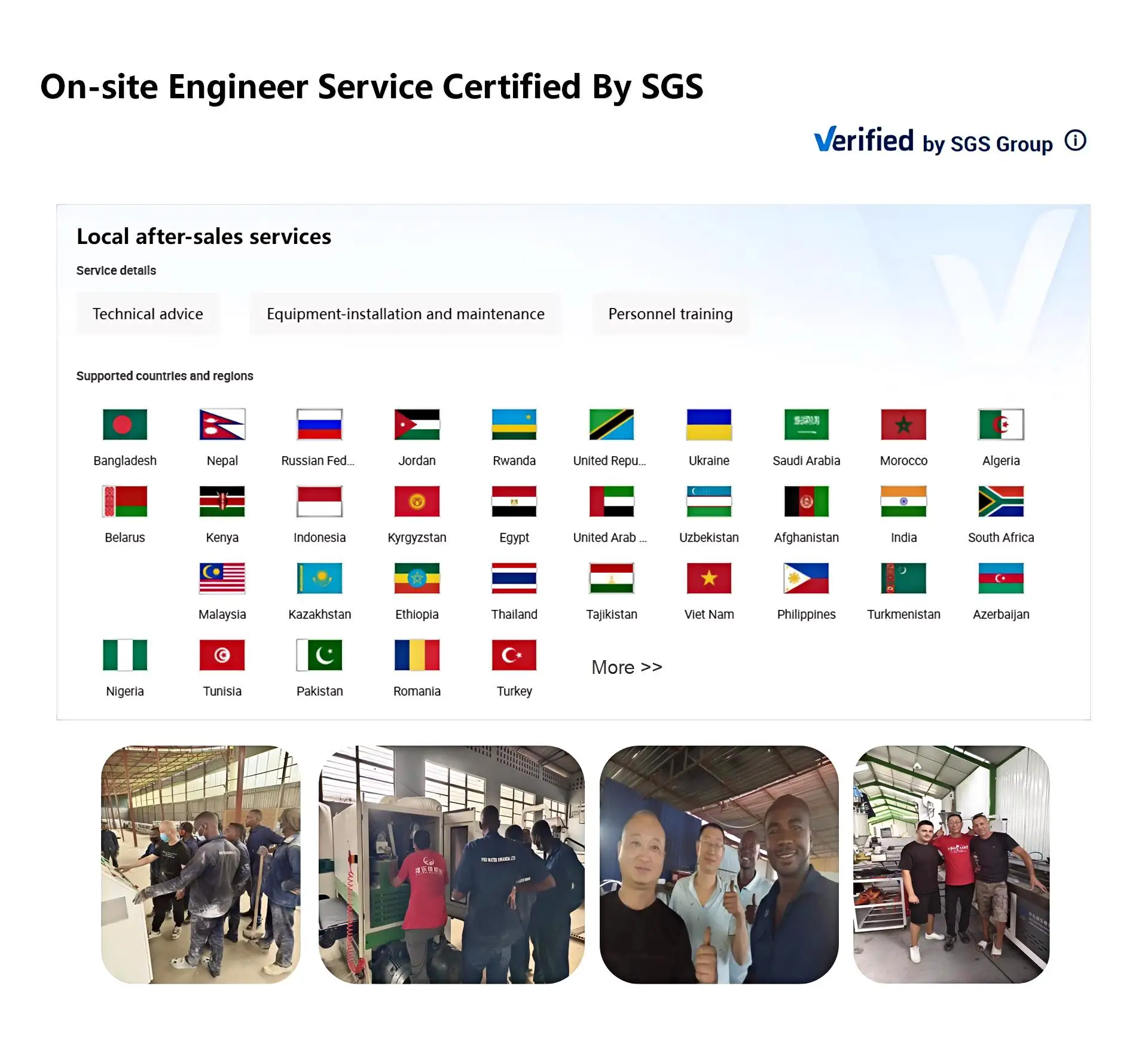

- Поставщик: Qingdao Fullwin Plastic Machinery Co. Ltd.

Сохранить в закладки 1601285346587:

Описание и отзывы

Характеристики

Production Description

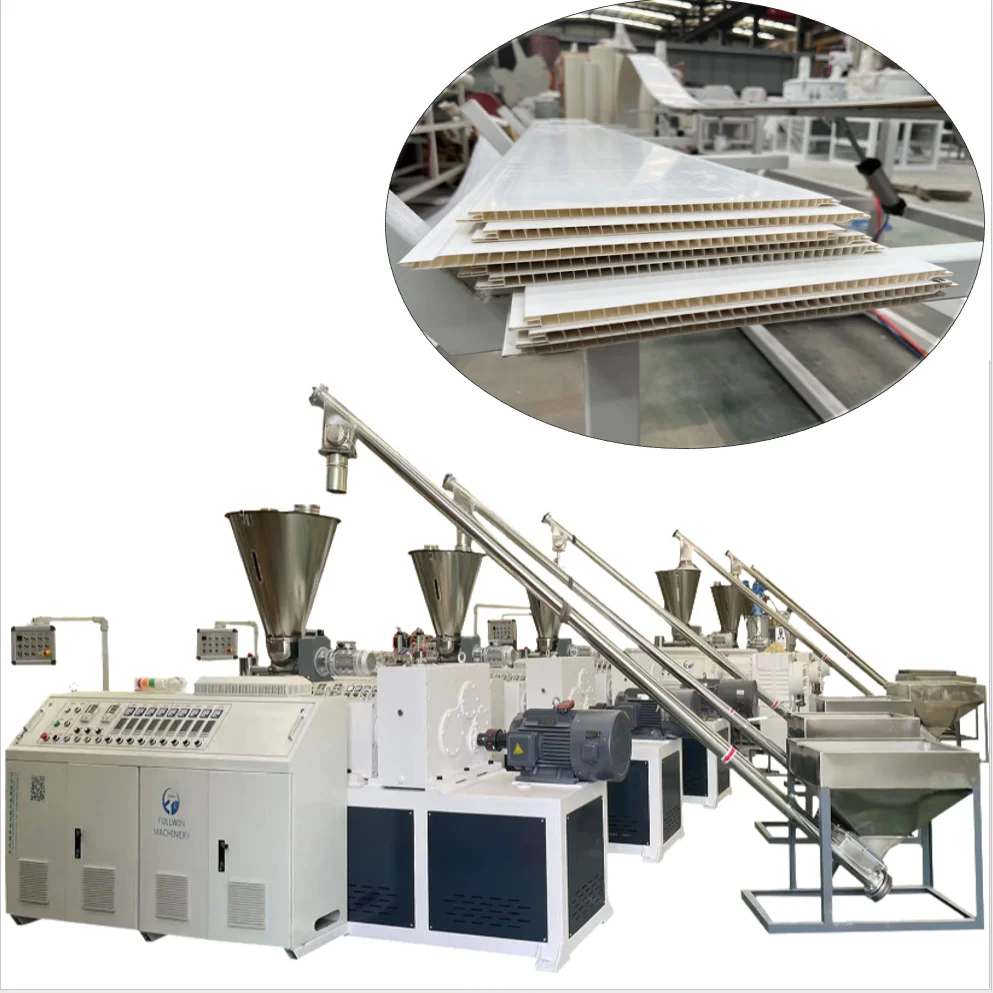

Multifunctional Slat PVC Ceiling Wall Panel Extrusion Line with high output

indoor decorate PVC Ceiling panel Machine PVC Board Panel Making Machine production line equipment

can be customized

Processing flow of plastic pvc WPC profile making machine extrusion line:

PVC powder + additive → mixing → spring feeding → twin screw extruder → profile mould and calibrator→ haul off machine → cutting machine → discharging rack(stacker)

Machine Details

NO. | Name | QTY |

1 | Auto feeder | 1 |

2 | Double screw extruder(conical screw) | 1 |

3 | Die head mould | 1 |

4 | Calibrating platform | 1 |

6 | Haul off | 1 |

7 | Cutting machine | 1 |

8 | Stacker | 1 |

1. Conical double screw extruder 65/132 with Spring feeder

Screw barrel design:Surface nitriding,nitriding thickness 0.4mm-0.7mm, hardneed≥940HV,Nitriding is a chemical heat treatment

process in which nitrogen atoms seep into the working surface at a certain temperature in a medium.

After Nitriding,the product have excellent wear resistance, fatigue resistance, corrosion resistance and hightemperature resistance,and more longer working life.

Barrel heater (new design,save about 30% electric)

process in which nitrogen atoms seep into the working surface at a certain temperature in a medium.

After Nitriding,the product have excellent wear resistance, fatigue resistance, corrosion resistance and hightemperature resistance,and more longer working life.

Barrel heater (new design,save about 30% electric)

2. PVC WPC Profile extrusion Die and mould

Our advantage:vacuum forming mould,connect water for cooling the product.make the product more beautiful and sizing more better quality.

3. Calibrating platform

Stable materials:304# stainless steel

Cooling type:water and air cooling

Cooling type:water and air cooling

4. Hauling off machine with cutter

Clamping mode:Pneumatic

Cutting way:Sawblade cutting

Cutting way:Sawblade cutting

5. Stacker

Mode:Pneumatic (Pneumatic transmission) *Length:6000mm *Adjustable limit switch number:2 pcs

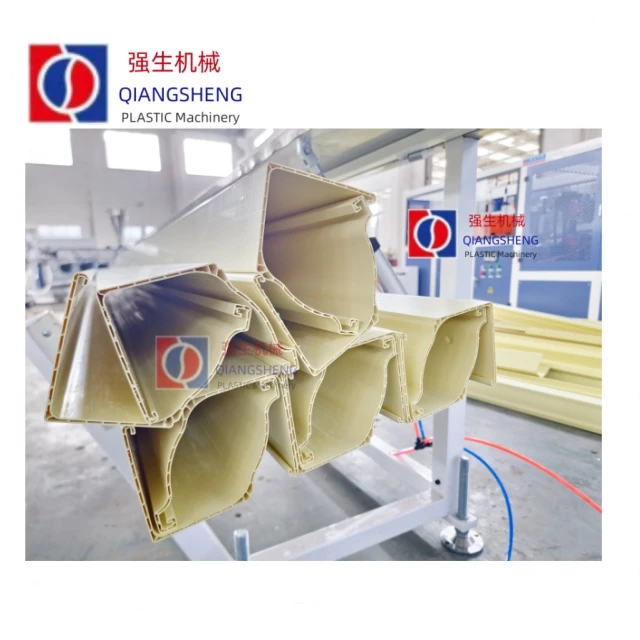

Final products

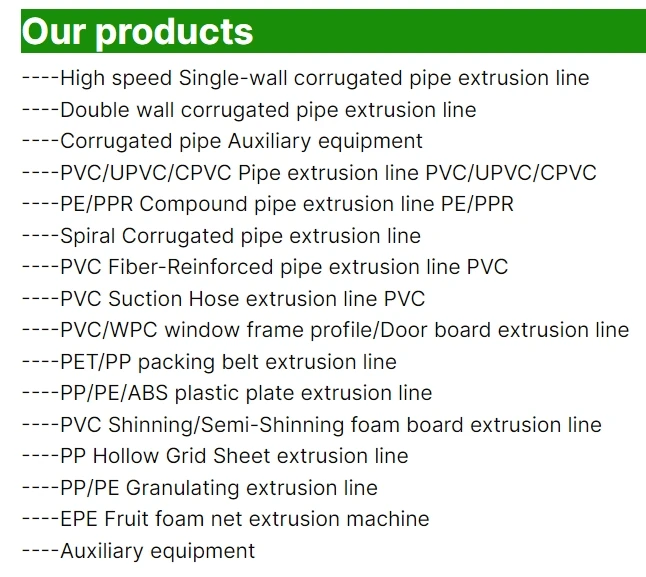

FULLWIN Main product

Single Wall Corrugated Pipe Machine

Production speed :20-35m/min Pipe Diameter :12-50mm Application :

shisha hookah pipe,electric conduit pipe, construction material etc

shisha hookah pipe,electric conduit pipe, construction material etc

with FULLWIN Unique design and high output

PVC PP PE PPR HDPE Pipe Machine

Diameter : 20-110mm, 125-250mm,315-630mm 630-1200mm

Can be used to produce PPR hot and cold water pipes,PP/PE/HDPE pipes, silicon core tubes.

Can be used to produce PPR hot and cold water pipes,PP/PE/HDPE pipes, silicon core tubes.

Plastic PVC Profile Machine

Mainly used for window profiles, electric trunking, grating panels,wall panel and ceiling panel etc decoration material.Customized

according to different profile sections and molds

according to different profile sections and molds

PE WPC Profiles extrusion machine

The material is the WPC PE, can be molded products have a wood-like look and feel. Widely used in outdoor decking floor,railings,walking trails, outdoor tables

and chairs, benches and pallets.

and chairs, benches and pallets.

PP Hollowness corrugated sheet line

Thickness: 1.6mm-18mm.Width:

915-1800mm.

The size error is small, can nail, can gouge, corrosion resistance, flame retardant strong and many other advantages.

The size error is small, can nail, can gouge, corrosion resistance, flame retardant strong and many other advantages.

PVC marble sheet production machine

With the conical twin screw extruder, with the PVC power material feeding.

The PVC marble sheet widely used for the interior decorate like the home TV walls,hotels,hall decoration, etc

FULLWIN Main product

Packing and delivery

FULLWIN Factory

Похожие товары

QiangSheng завод WPC UPVC дождевой желоб экструдер для полукруглых и квадратных водосточных дренажных систем

2 773 187,50 ₽ - 3 105 970,00 ₽

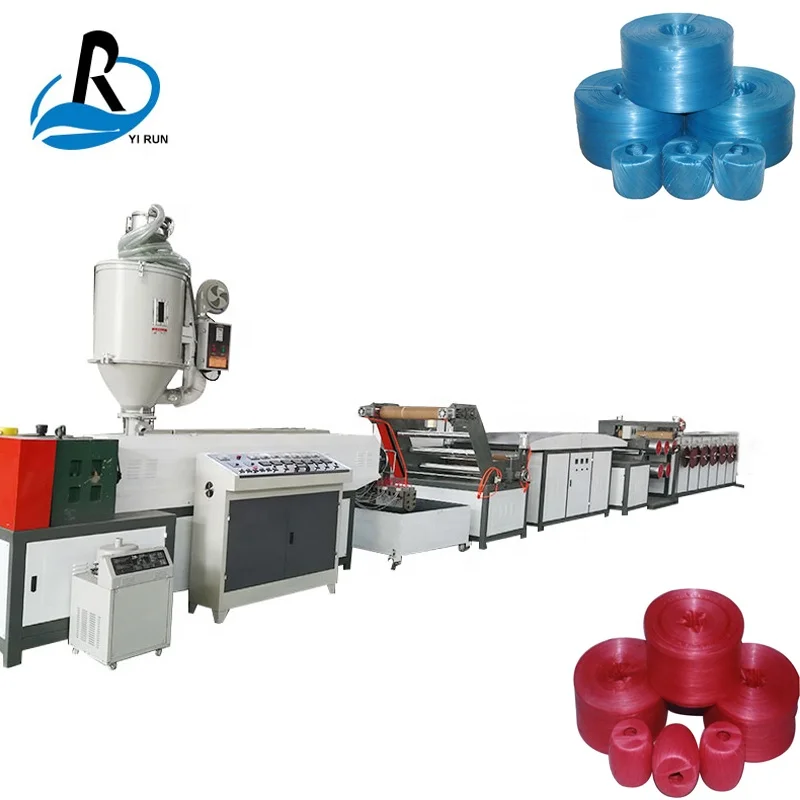

ПОЛИПРОПИЛЕН КИСТИ МОНОВОЛОКНА ЭКСТРУЗИОННАЯ ЛИНИЯ

полипропилен пэ пвх переработки пластика гранулирования линия

20-630mm пластиковых hdpe полиэтилен низкой плотности pe машинного производства труб/линии

Автоматический вспомогательный Winder пластиковой круглой проволоки и плоского машина для обвязки шпагатом

состав wood+recycled пластиковые машины wpc

32 мм HDPE гидравлический спиральный шланг гвардии машина

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $