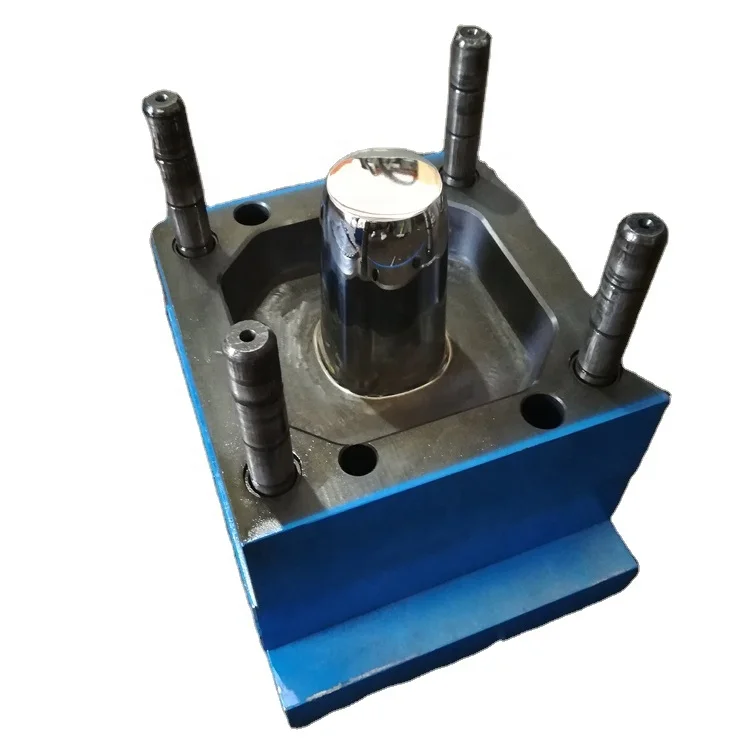

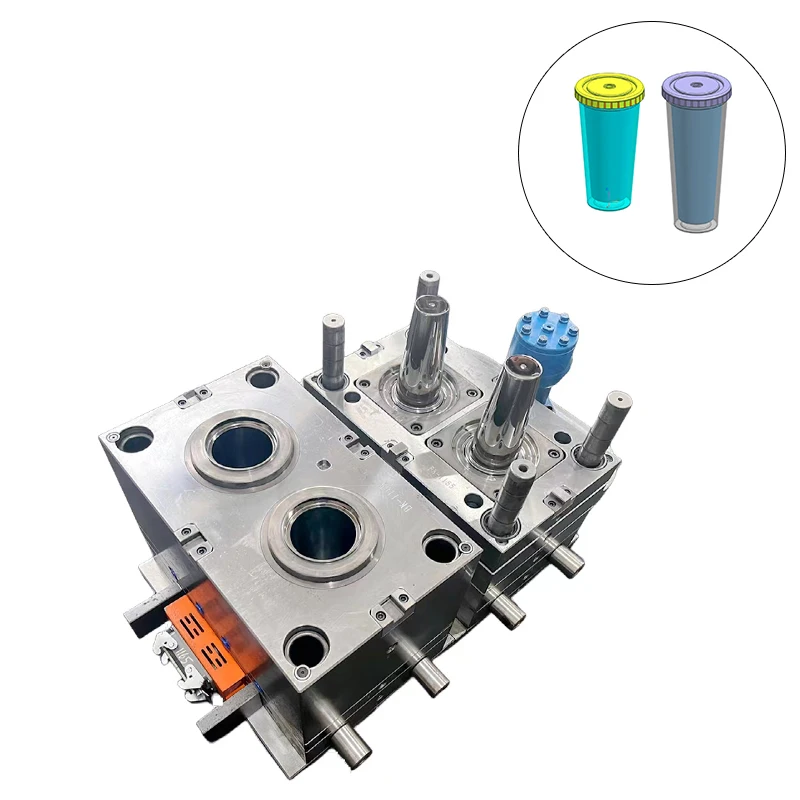

Быстрое прототипирование с литьевыми пластиковыми формами

- Категория: >>>

- Поставщик: Foshan Exhibition Jie Technology Co. Ltd.Foshan Ltd.

Сохранить в закладки 1601288568502:

Описание и отзывы

Характеристики

Supply Services

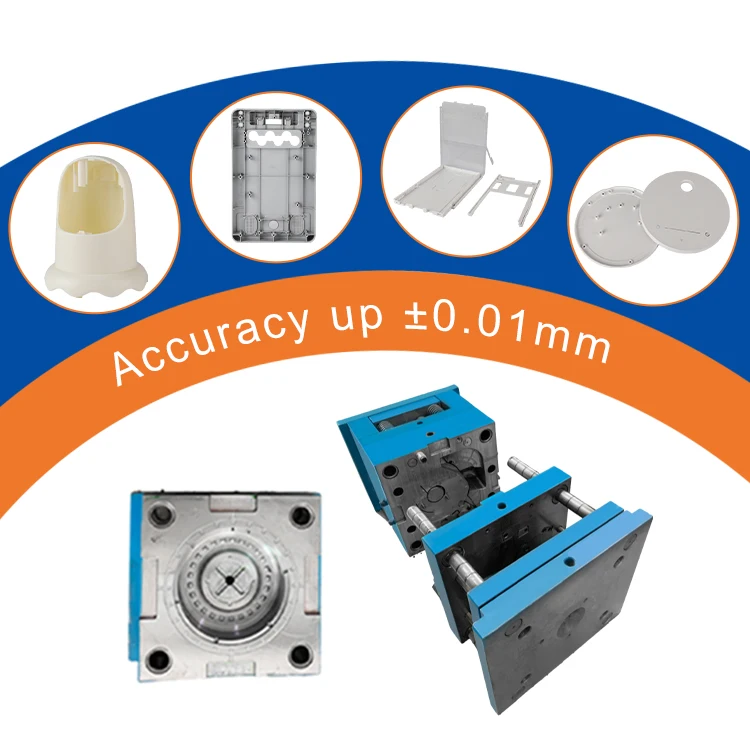

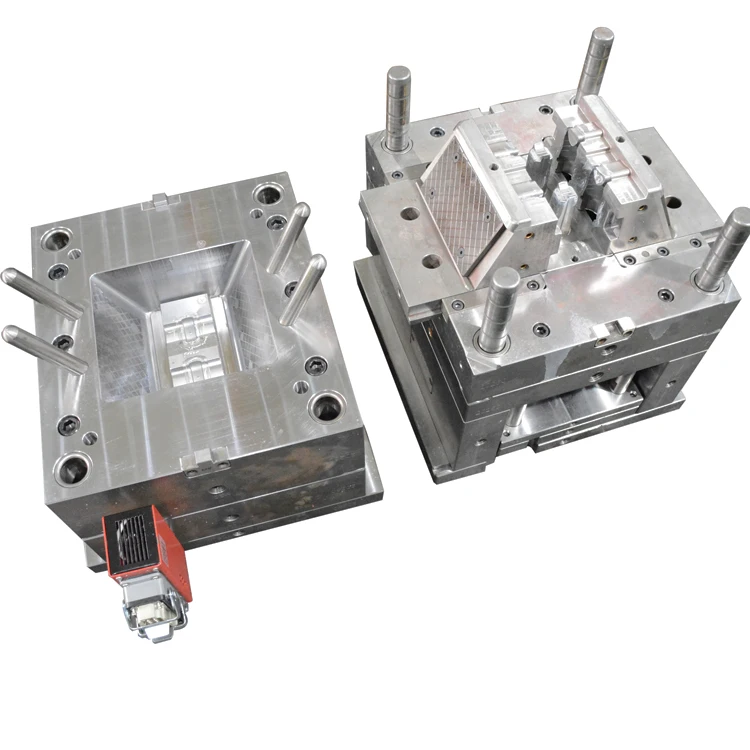

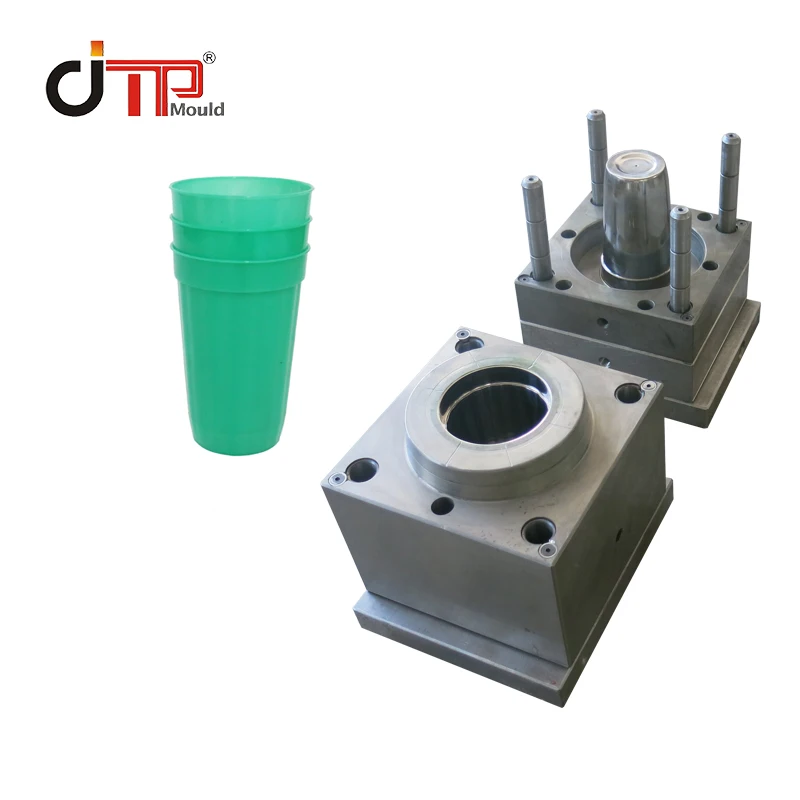

One-stop plastic injection molding production, plastic precision mold manufacturing.

plastic products after screen printing, radium carving, assembly, packaging.

How to get a quote quickly:

1.Please provide 3D/2D drawings or physical objects.

2. Materials for the required products.

3. Quantity of each order and estimate the annual demand.

plastic products after screen printing, radium carving, assembly, packaging.

How to get a quote quickly:

1.Please provide 3D/2D drawings or physical objects.

2. Materials for the required products.

3. Quantity of each order and estimate the annual demand.

Manufacturing Process

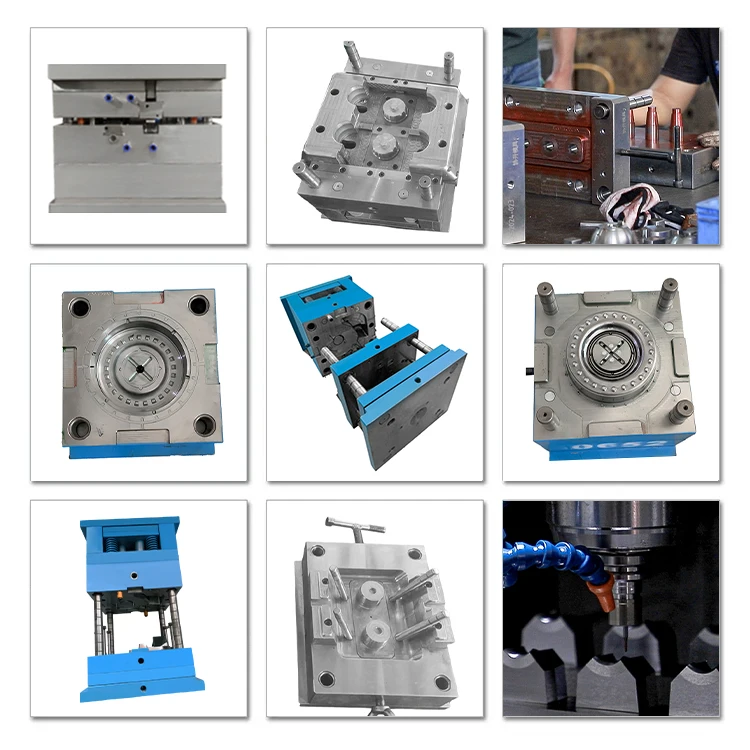

Mold Making Shop

Our basic guidelines for plastic injection molding include important design considerations to help improve part

moldability,enhance cosmetic appearance, and reduce overall production time.

moldability,enhance cosmetic appearance, and reduce overall production time.

WEDM

The accuracy of wire cutting is comparable to that of a grinder (0.005 mm unit)

In addition to straight cutting, it can also cut into arcs and process complex shapes, such as a combination of straight and

arcs.

As long as it is a conductive material, it can be machined from sheet to cemented carbide regardless of the thickness, size and

hardness of the material.

arcs.

As long as it is a conductive material, it can be machined from sheet to cemented carbide regardless of the thickness, size and

hardness of the material.

EDM Electrodes

There is no direct contact between the tool electrode and the workpiece, but there is a spark discharge gap. This gap is generally

between 0.05~0.3mm, and sometimes it may reach 0.5mm or even larger. The gap is filled with working fluid, and the high pressure

Pulse discharge, discharge corrosion on the workpiece.

between 0.05~0.3mm, and sometimes it may reach 0.5mm or even larger. The gap is filled with working fluid, and the high pressure

Pulse discharge, discharge corrosion on the workpiece.

CMM

There are many features measured by the CMM, and almost all types of dimensional measurements can be measured by the CMM. Through

the structural features, it is possible to detect flatness, roundness, concentricity, etc.

the structural features, it is possible to detect flatness, roundness, concentricity, etc.

Name | Plastic Injecition Mold | ||||||

Serve | OEM ODM Accepted | ||||||

Custom Pricing | We Will Give You A 100% Satisfactory Price | ||||||

Product Dispose | Polishing finish,Texture Finish,Glossy Finish,Rubber Painting,Painting, Slik print etc serve | ||||||

Quality | We Will Do 100% Inspection Before Shipment | ||||||

Use Material | ABS,PMMA,PS,HDPE,TPE,TPU,AS,PP,PPS,PC,PE,POM etc | ||||||

Typical Used For | Pet plastic Accessories | ||||||

Digital Electric Appliance | |||||||

Supermarket Shelf | |||||||

Automobile Peripheral Parts | |||||||

Agricultural Plastic Parts | |||||||

Maternal & Medical | |||||||

Beauty & Fitness | |||||||

Household Kitchenware | |||||||

Other Plastic Parts | According to customer requirements | ||||||

Other Service | Contact us | ||||||

Why Choose Us

Material Customization

Ordering Process

Our Factory

Certificate Display

FAQ

Q1: Why choose injection molding?

A1: lt minimises moulding costs and is a highly repeatable way of producing plastic or

elastomeric parts with high precision, Once set up, it can manufacture a large volume of

parts per hour, from a wide range of different plastics plus other materials such as liquid

silicone rubber.

Q6: How effective is injection moulding?

Q2: Will 3D printing replace injection molding?

A2: No, 3D Printing Won't Replace Injection Molding.

Injection molding requires the use of a specialized machine. injection molding machines

can typically create objects faster, more efficiently, and in many cases, with better

dimensional accuracy than 3D printers.

Q4:ls injection moulding cheap or expensive?

Q3: What are the pros and cons of injection moulding?

A3:1.lt allows for complex geometries with tight tolerances.

2. It's compatible with a wide range of materials and colors.

3. lt's very efficient.

4. It offers high repeatability and reliability.

5. You can reuse material.

6. Start-up costs are high.

7.initial lead times are long.

A3:1.lt allows for complex geometries with tight tolerances.

2. It's compatible with a wide range of materials and colors.

3. lt's very efficient.

4. It offers high repeatability and reliability.

5. You can reuse material.

6. Start-up costs are high.

7.initial lead times are long.

Q4:ls injection moulding cheap or expensive?

A4: The start-up costs for a large run can be expensive, but the price for the project

becomes better and better as you continue to produce. lf you're looking at price per unit,

plastic injection molding is one of the cheapest, most cost-efficient forms of manufacturing.

Q5:ls injection molding faster than 3D printing?

A5: Injection molding is ideal for high-volume production and for projects with longer

turnaround times. Although it can be used with parts of various sizes, injection molding

offers less design freedom. 3D is better for low-volume production runs, designs with

frequent changes, and projects with quick turnaround times.

Q6: How effective is injection moulding?

A6: Efficient high production.Once you have developed the moulds, the process is

extremely fast with cycle times as short as 10 seconds. lt is excellent for medium

and high-volume production runs for anything from 10,000 parts to well over 100,000

depending on what moulds you use.

Похожие товары

Индивидуальные сервисные чашки для напитков Прецизионная формовочная форма пластиковые формы кофе инъекций бытовые изделия заглушки наушников

Заводская поставка дешевая Термоформовочная пластиковая чашка изготовленная на заказ стальная форма для термоформования высокое качество

Taizhou Заводская индивидуальная горячая Распродажа Высококачественная пластиковая пресс-форма для воды с одной полостью

Видео! Изготовленная на заказ фабрика Taizhou полосатая форма для пластиковых стаканчиков литья под давлением стеклянная

Китайский изготовленный на заказ высококачественный производитель пресс-форм для литья пластмасс под давлением

18 000,00 $

Индивидуальные литьевые пресс-формы для пластиковых форм

Высококачественная Заводская индивидуальная форма для лазерного ножа специальной упаковки

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $