Shanghai Zenith XZM микро порошковая мельница создает высококачественный Бентонитовый Порошок для гранул стального завода

- Категория: >>>

- Поставщик: Shanghai Zenith Machinery Co. Ltd.Shanghai Ltd.

Сохранить в закладки 1601289619709:

Описание и отзывы

Характеристики

The Shanghai Zenith XZM ultrafine powder mill has multiple functions in the field of bentonite powder production in steel mills, including efficient powder production, improved pellet quality, reduced production costs, and superior environmental performance. These advantages have led to the widespread application and recognition of this equipment in the steel industry, and it plays a significant role.

The advantages of Shanghai Zenith XZM ultrafine powder mill in the field of bentonite powder production in steel plant pellet production:

Efficient powder production capability

The XZM ultrafine powder mill adopts modern grinding technology and has strong crushing, rolling and grinding performance. This equipment can efficiently process bentonite raw materials into fineness requirements that meet the production needs of steel mill pellets. By adjusting the parameters of the equipment, it is easy to achieve fineness control of bentonite powder to meet different production needs.

Improve the quality of pellets

Bentonite, as an important raw material for steel mill pellet production, has a direct impact on the quality of pellets due to its fineness and uniformity. The XZM ultrafine powder mill can process bentonite into a powder with uniform fineness and reasonable particle size distribution, which helps to improve the strength and stability of the pellets. Meanwhile, uniformly fine bentonite powder can be better mixed with raw materials such as iron ore powder, thereby improving the overall quality of the pellets.

lower production cost

The XZM ultrafine powder mill has the characteristics of high output and low energy consumption. At the same fineness of finished products and motor power, its output is higher than that of air flow mill and agitator mill, while the system energy consumption is lower. This means that using the XZM ultrafine powder mill can more effectively utilize energy and raw materials, reducing production costs. In addition, the maintenance cost of this equipment is relatively low, which can save a lot of operating expenses for enterprises.

Superior environmental performance

During the milling process, the XZM ultrafine powder mill is equipped with environmentally friendly equipment such as pulse dust collectors and mufflers. These devices can effectively reduce dust pollution and noise pollution, meeting national environmental standards. This is of great significance for protecting the production environment, ensuring employee health, and achieving sustainable development of the enterprise.

The process flow of Shanghai Zenith XZM ultrafine powder mill in the field of bentonite powder production in steel plant pellet production:

The process flow of Shanghai Zenith XZM ultrafine powder mill in the production of bentonite powder in steel mills includes steps such as raw material preparation and crushing, drying and iron removal, grinding and grading, collection and packaging, as well as quality control and monitoring. These steps are interrelated and interdependent, together forming a complete bentonite milling process, mainly including the following steps:

Raw material preparation and crushing

Raw material collection: Collect raw materials from bentonite mines to ensure that the quality of the raw materials meets the requirements of steel mill pellet production.

Crushing treatment: Use a crusher (such as a jaw crusher or hammer crusher) to crush large pieces of bentonite to a feed fineness that can enter the mill (generally controlled between 15mm~50mm). The purpose of this step is to reduce the size of the raw materials for subsequent grinding processing.

Drying and iron removal

Drying treatment: Natural or heated drying is used to remove moisture from bentonite raw materials to prevent excessive moisture from affecting the grinding effect and product quality. The drying temperature should be controlled within a certain range (such as below 250 ℃) to avoid changing the properties of bentonite due to excessive temperature.

Iron removal treatment: Before the raw materials enter the mill, iron removal equipment (such as a self dumping iron remover) is used to remove iron impurities from the raw materials and ensure product quality.

Grinding and Grading

Grinding treatment: The dried and iron removed bentonite raw material is sent to the XZM ultrafine powder grinder for grinding. During the grinding process, the grinding roller applies pressure to the material inside the grinding disc under the action of the hydraulic device and transmission arm, achieving the squeezing, shearing, and grinding of the material. At the same time, the airflow is rapidly and uniformly sprayed upwards from the wind ring at the edge of the grinding disc, blowing up the overflowing material

And conduct sorting.

Grading treatment: The bentonite powder after grinding is graded by a classifier. The powder with qualified fineness is smoothly discharged through the classifier, while the powder with unqualified fineness is returned to the grinding machine for re grinding. The purpose of this step is to ensure that the fineness and uniformity of the bentonite powder meet the production requirements.

Collection and packaging

Collection and processing: After classification, qualified bentonite powder enters the dust collector (such as pulse dust collector or cyclone collector) with the airflow for separation and collection. The collected powder is sent to the next process through the discharge valve.

Packaging treatment: Packaging the collected bentonite powder. According to production needs, bulk or packaging machines (such as small bags/ton bags) can be selected for packaging before leaving the factory.

Quality Control and Monitoring

Throughout the entire process, it is necessary to monitor and adjust parameters such as temperature, humidity, and rotational speed for each process step to ensure product quality and production efficiency. At the same time, it is necessary to conduct quality testing on the finished products to ensure that they meet the requirements of steel mill pellet production.

The Shanghai Zhenlishi XZM ultrafine powder mill not only performs outstandingly in the bentonite powder production industry in steel plant pellet production, but also can process more than 300 types of minerals such as limestone, calcite, calcium carbonate, dolomite, gypsum, kaolin, marble, talc, barite, bentonite, coal, charcoal black, petroleum coke cement, etc. It is still professional, efficient, and environmentally friendly. The fineness of this series of ultrafine powder mills can be freely adjusted between 100-2500 mesh, and the processing capacity range can reach 500-25000 KGPH, which has been highly recognized and praised by domestic and foreign customers.

Shanghai Zenith specializes in producing large-scale 10μm ultrafine powder grinding mills:

Zenith multi function grinding mills is widely used in making fine powder or micro powder, a new kind of machine for producing ultrafine powder. Ultrafine Grinding MillMicro Fine Powder MillPulverizer Machine is mainly used for grinding the material with middle and low hardness, moisture below 6%, and the material should be non-explosive and non-flammable, such as: calcite, chalk, limestone, dolomite, kaolin, bentonite, steatite, mica, magnetite, iolite, pyrophillite, vermiculite, meerschaum, attapulgite, diatomite, barite, gypsum, alunite, graphite, fluorite, phosphate ore, potassium ore pumice, etc. The size of the finished product from fine grinder pulverizers can be adjusted between 325-2500 mesh.

Cheaper Price XZM 1500 mesh Grinding Mill Pulverizer for stone powder production line |

After crushed by hammer crusher, the large materials become small ones and are sent to storage hopper by elevator, edge of then evenly sent to the upper distribution plate of the turnplate by vibrating feeder and sloping feeding pipe. When the multi function grinding mills is at work, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the turnplate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, crushed and grinded by the rollers.

The high-pressure air blower constantly inhales air within the grinding machines in pakistan and, in turn, the air flow with crushed materials are brought to the classifier whose high-speed impeller will screen the airflow: the unqualified particle size will fall and return to the grinding machines in pakistan for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. of the qualified powders will fall an exit from the discharging valve at the bottom; a small proportion of the fine powders, with airflow, moves to the dust cleaner, and clings to the surface of the filter bags. At the same time, the fine powders clinging to the surface fall down by the sudden vibration of the filter bags, which is caused by the instantly ejected high-pressure gas controlled by the pulse valve. The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed. In addition, filtered clean air will be emitted from the air outlet of muffler in the end.

Shanghai Zenith specializes in producing large-scale 10μm ultrafine powder grinding mills for Features:

1.High pressure spring design.

2.Smoothly vibration reduce design

3.Convenient vane adjust design.

4.The machine has a strong material applicability , which suits for many kinds of material whose Moh’s hardness is less than 9.3.

5.Grinding device adopts superimposed multistage seal, sealed performance is good.

Shanghai Zenith specializes in producing large-scale 10μm ultrafine powder grinding mills for application:

multi function grinding mills is widely used in many industrial fields, such as building, chemical, chemical fertilizer, metallurgy, mining, nonmetal,abrasive, bearing materials, ceramic, steel, thermal power, bricks & tiles, coal industry, etc. It can grind these materials which are 9 or less on the Meshesscale, and moisture is below 6%., and they should be non-explosive and non-flammable mining materials. The final size can be adjusted from 30 to 400 meshes easily.There are thousands of materials our mtm power can grind.

| Model | Number of roller (piece) | Ring diameter (mm) | Number of ring (piece) | Max. inlet size (mm) | Final size (mesh) | Capacity (kg/h) | Main equipment rotate speed (r/min) |

| XZM221 | 21 | Φ800 | 3 | ≤10 | 325-2500 | 600-5500 | 235 |

| XZM224 | 24 | Φ900 | 3 | ≤20 | 325-2500 | 700-5500 | 235 |

| XZM236 | 36 | Φ1000 | 4 | ≤20 | 325-2500 | 700-7500 | 235 |

| Basic data | Item | Unit | specification | ||

| XZM221 | XZM224 | XZM236 | |||

| Motor of main machine | Model | - | Y250M-4 | Y280S-8 | Y2-315L-6 |

| Power | kw | 55 | 37×2 | 110 | |

| Speed-adjustable motor | Model | - | Y180M-4 | Y180L-4 | Y2VP200L-4 |

| Power | kw | 18.5 | 22 | 30 | |

| Motor of elevator | Model | - | Y100L-4 | Y100L-4 | Y100L-4 |

| Power | kw | 3 | 3 | 3 | |

| Motor of blower | Model | - | Y225M-2 | Y225M-2 | Y280S-2 |

| Power | kw | 45 | 55 | 90 | |

| Hammer crusher | Model | - | PC300*400 | PC300*400 | PC400*600 |

| Power | kw | 11 | 11 | 18.5 | |

| Electromagnetic Vibrating feeder | Model | - | GZ1F | GZ1F | GZIF |

| Power | kw | 0.06 | 0.06 | 0.06 | |

| Discharge valve | Model | - | ZJD-200 | ZJD-200 | ZJD-200 |

| Power | kw | 0.75 | 0.75 | 0.75 | |

| Note: If there is any change of above specification, it is all according to the booklet with machine. | |||||

Ways of Packing:

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit zenith working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of Zenith, they are now strategically located home and abroad, working for our customers.

Shanghai Zenith is committed to providing users with the new, reliable and productive equipment. Zenith engineers have rigorously tested our products .

1.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2.Guaranteed:

If products’quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about price?

Yes, we are factory and be able to give you the lowest price than market one, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”.

4.Service and Payment Terms?

A. We usually accept T/T, L/C;

B. T/T: 30% in advance as down payment, the balance before delivery;

C. We take pictures of finished products before delivery.

A VARIETY OF TRUSTED EXPERIENCE ZENITH has a variety of professional, reliable and efficient crushing lines all around the world. So customers have great confidence in us. |

INFINITE BRAND VALUE What ZENITH is doing is customizing economical and suitable production lines for customers and building brand value. |

1200,000 SQUARE METERS OF PRODUCITION AREA 6 large-scale manufacturing bases occupy 1200,000 square meters in total. So quick delivery is a matter of course. |

Shanghai Zenith Mineral Co., Ltd. is a hi-tech, engineering group. We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices. Our products have been sold to 120 countries and areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future.

Zenith Factory

Headquarter of Zenith is located in Shanghai, China and now we have two manufacturing bases as our strong support. One is located in Shanghai about 450,000 square meters, and the other is in Qidong city, about 600,000 square meters. It takes about one-hour driving from Shanghai to Qidong city.

Exhibition

Zenith participate in various exhibitions frequently,such as Bauma China,China Import and Export Fair , Asia-pacific's International Mining Exhibition, Bauma Africa, CONEXPO Latin America , etc.

If you are interested with our products, please don't hesitate to contact us now!

You can tell me the following questions, Then I can send you accurate quotation, including additional discount!

1. Which machine do you need? like stone crusher, grinding mill or beneficiation machine, etc.

2. what is your raw material plan to process? like limestone, granite or inron ore, etc.

3. The capacity you need. Like 100 tones per hour or 2000 tones per day.

4. Your contact information. Both Email and phone number are essential, we can contact you easier.

Now,please click the following contact to send us email or chat online!

Похожие товары

Напрямую с фабрики известняк Raymond шлифовальный станок

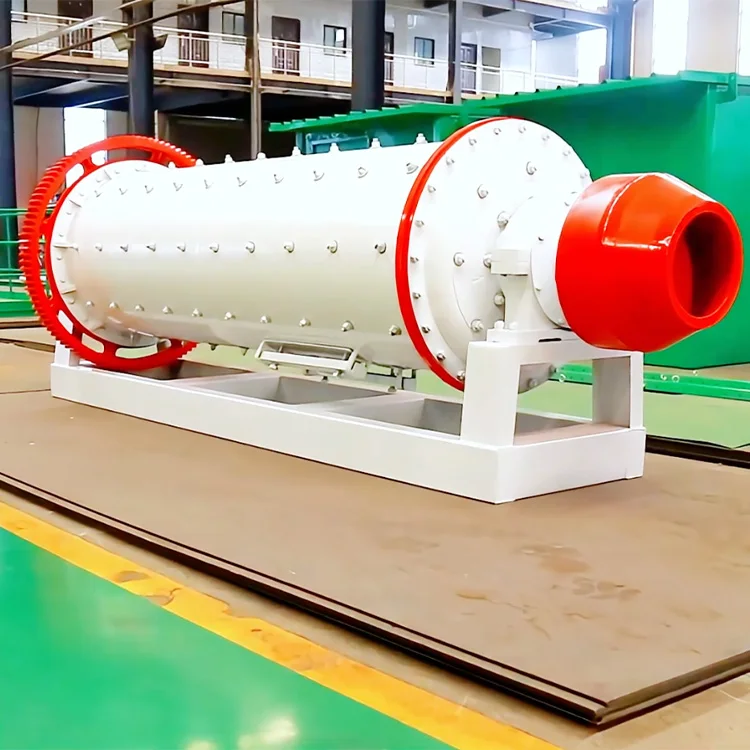

Small Scale 900*1800 Ball Mill for Silica Sand Magnetite Grinding

Машина для измельчения гипсового порошка и доломита роликовая Мельница raymond продажи

Shanghai ZENITH с помощью мягкого стартера для обеспечения бесперебойной работы XZM224 доломитовая ультратонкая мельница

Высокое качество 200TPD влажный тип 1830x4500 Золотая шина шаровая мельница заводская цена на продажу

Экологически Чистая модель 5R4121 Raymond Mill 2 высокопрокатный стан

Мельница Raymond для химической промышленности мельница Кальцита карбоната кальция мрамора

Новые поступления

Новинки товаров от производителей по оптовым ценам