Высокопроизводительные многофункциональные рисовые Кукурузные Закуски Шнековый экструдер для производства риса

- Категория: >>>

- Поставщик: Jinan FLD Machinery CO. LTDJinan LTD

Сохранить в закладки 1601291323143:

Описание и отзывы

Характеристики

1.Extruded Corn Puff Cheese Ball Making Machine Description:

Puffed Snack Food Making Machine is improved and developed based on advanced technology by Jinan FLD Machinery Company. The machine performance and products quality reach to the most advanced level in the world. This line has features of flexible collocation, extensive applied raw materials, various snacks and easy operation. It is fully automatic from mixing, extruding, shaping, cutting, drying to flavoring in one-pass operation. By changing the dies and process technology, you can produce various shapes of puffing snacks such as rings, flowers, balls, strips, moons, stars etc. Also, you can produce core-filling snacks with the same line. All the puffed food taste crispy, easy to be digested. They meet with great favor home and abroad.

1. Raw materials: corn flour, wheat flour, rice flour, etc.

Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder

2.Extruded Corn Puff Cheese Ball Making Machine Products:

Mixing system---Extrusion system----Drying system----Flavoring system--Packing system

3.Technical Parameter of Extruded Corn Puff Cheese Ball Making Machine:

| Model | SLG65-III | SLG70-III | SLG85-III |

| Install Power | 76KW | 95kw | 178kw |

| Power Consumption | 54KW | 66kw | 125kw |

| Capacity | 120-150KG/H | 240-260kg/h | 300-500kg/h |

| Dimension | 17×2×2.5m | 22×2×2.5m | 26×2×3.5m |

4.Main equipment of Extruded Corn Puff Cheese Ball Making Machine:

Mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine.

|

| |||||||||||||

|

| |||||||||||||

|

| |||||||||||||

|

| |||||||||||||

|

|

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

1. Daub coal oil on the surface of the Multi-function rice puffed corn snack machines corn puff screw extruder machine snack food making machine.

2. Plastic film as the inner packing.

3. Standard export wooden case as the outer packing.

4. Train, ship or depend on clients' requirement

Jinan FLD Machinery Co., Ltd. is a leading supplier of high quality Twin Screw Extruders and other food processing lines. We are located in Jinan city, the Capital of Shandong Province.

We have ten years' experience of working with our customers providing specialist designs and practical solutions for a wide range of process needs. We can improve client's equipment and provide related training on new advanced technique.

We can guarantee customers superior quality machines up to design requirements and perfect working state. Our technicians can also provide all kinds of relevant technology to make the food production clean, healthy and safe.

Q:How long is your guarantee time?

A:One year after commissioning.

Q:How is the installation?

A:We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

Q:If we show you our layout of factory, can you help to design the whole process line?

A:Of course, our experienced engineers and technical employee can help you to arrange the layout and installation of whole production line based on your real situation.

Q:How long is your delivery time?

A:Generally it is 7-10 days if the goods are in stock, or it is 20-25 days if the goods are not in stock, it is according to quantity.

Q:Will you help us if we accrue any problems in the future production?

A:Yes, we will always at your service. You can contact me via mobile, whatsapp, skype, viber, wechat and so on. I will help solve your problems as soon as possible.

Похожие товары

Машина для изготовления суши

1 2 3 4 колода торта хлеба печи пиццы выпечки пекарни цены коммерческие Индия США Китай промышленная пекарная печь ЦЕНЫ электрические

Китайский газовый двигатель 100kw природный газ биогаз генераторные установки

Машина для производства хлопьев

Машина для производства тортильи автоматическая линия по производству кукурузных чипсов оборудование жарки

Коммерческий квадратный вафельница машина флип промышленных

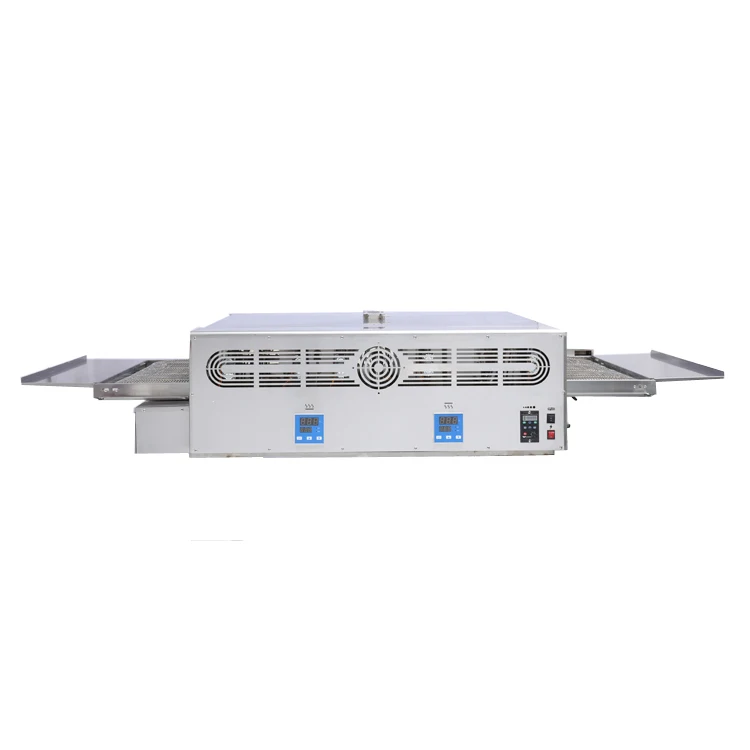

Конвейерная лента печь для пиццы/электрическая конвейерная пиццы/туннельная пиццы

Новые поступления

Новинки товаров от производителей по оптовым ценам