Медицинская силиконовая маска плесень Lim Жидкая резина LSR литьевая форма

- Категория: >>>

- Поставщик: Xiamen Neway Rubber & Plastic Products Co. Ltd.Xiamen Ltd.

Сохранить в закладки 1601291697250:

Описание и отзывы

Характеристики

Products Description

Item | Medical Silicone Mask Mould Lim Liquid Silicone Rubber LSR Injection Mold | |||

Part Material | All silicone rubber material | |||

Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB | |||

Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf | |||

Parameters | Inch, centimeter, millimeter, etc. | |||

Function | Industrial parts /daily supply / Medical grade supply. | |||

Surface Treatment | Matte, Common polishing, Mirror polishing, Texture, etc | |||

Mold Material | S136H, 718H, 2343, 8407, NAK80, P20, H13, #50 steel, etc.) | |||

Mold Precision | Depends on the product tolerance request. | |||

Mold Life-cycle | 100,000-500,000 shots. | |||

Packing | Pack with wooden box | |||

Sample | We can provide 3D printing sample to test the design before mould making. | |||

Price Tip | The price shown above is just for reference, final actual price depends on your design, material request, surface treatment, order qty, package request, etc. |

Medical Silicone Mask Mould Lim Liquid Silicone Rubber LSR Injection Mold

1. High Precision and Strict Quality Control.

2. Mould Life up to 500,000 shots.

3. Support After-Sales Service & Replacement of Spare Parts.

NEWAY is with In-house mold design and building capabilities for various mould making for rubber and plastic items. Hot runner system and cold runner system offered. We are very professional, and offer very high precision moulds.

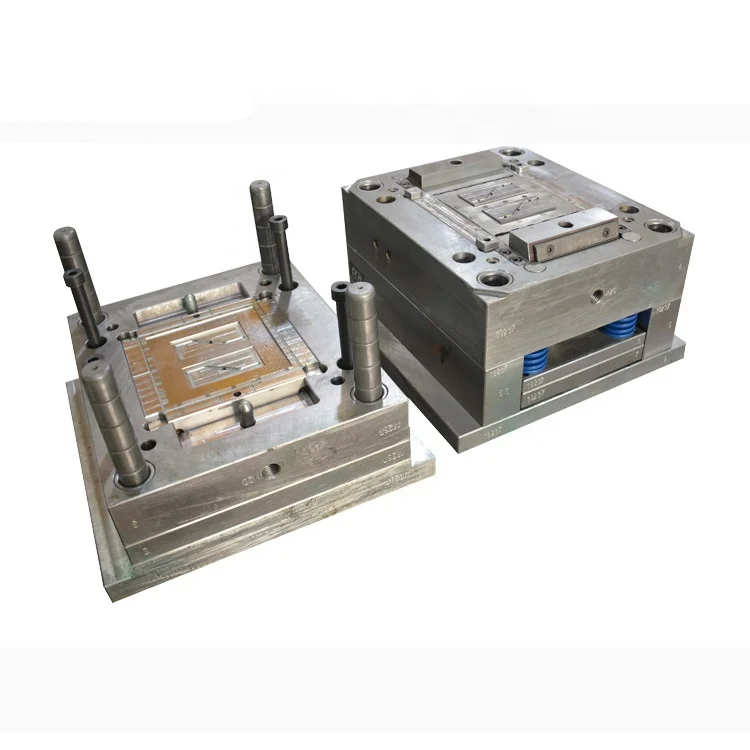

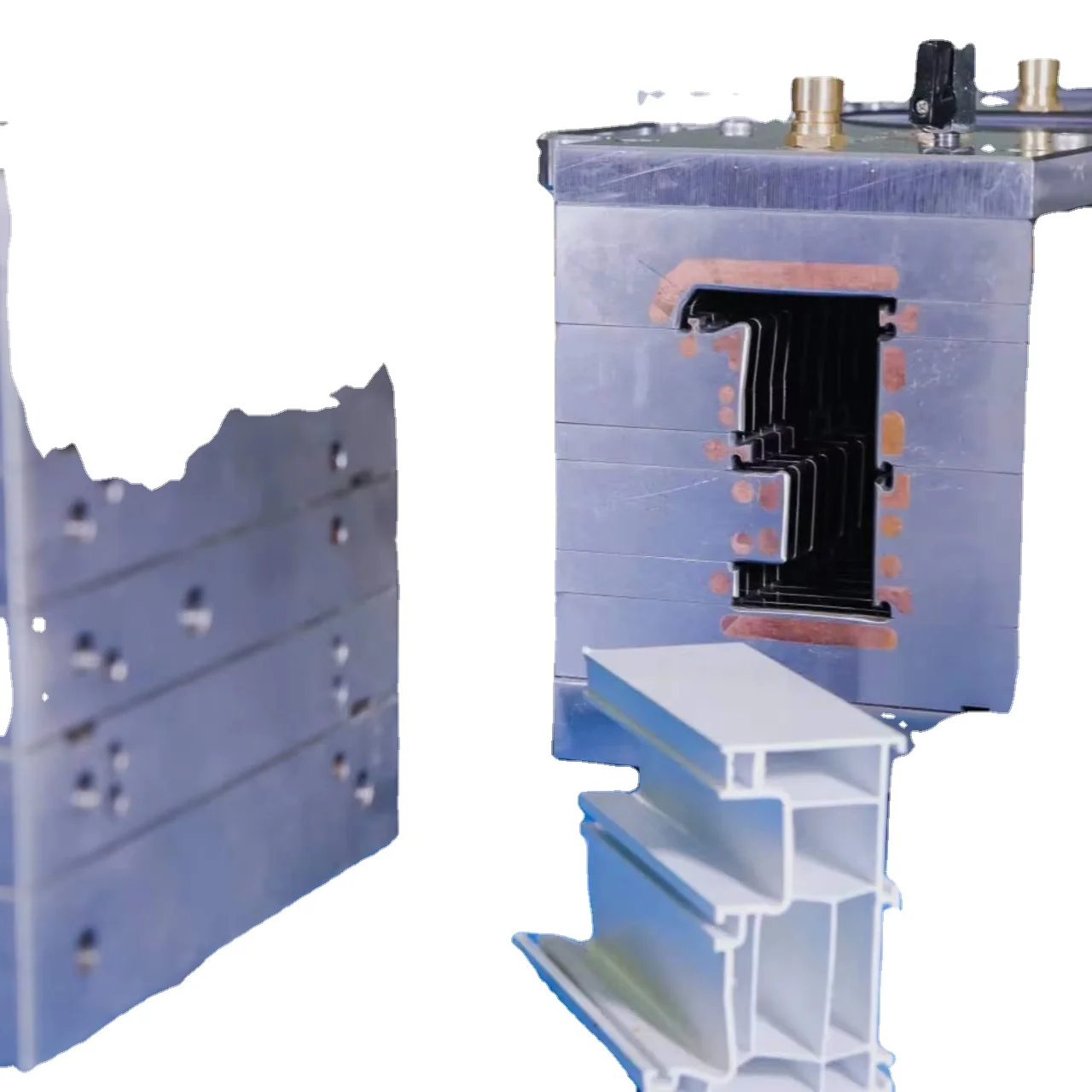

Cold Runner System for Reference

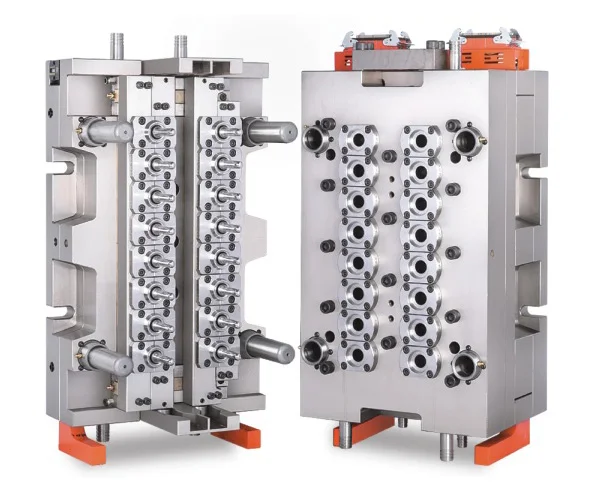

Hot Runner System for Reference

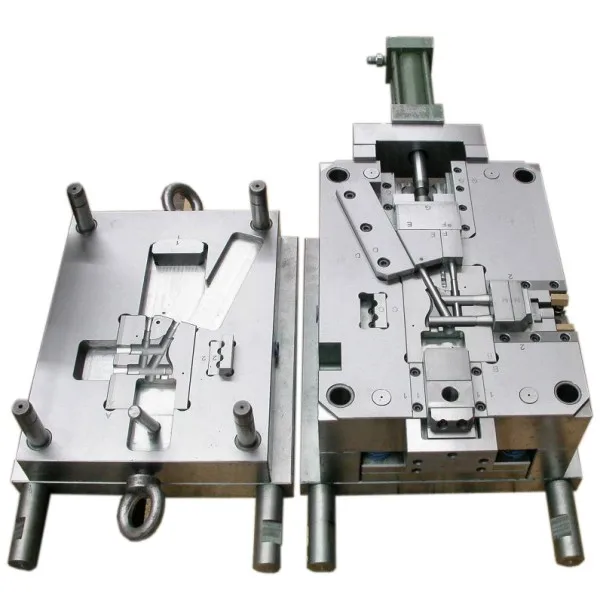

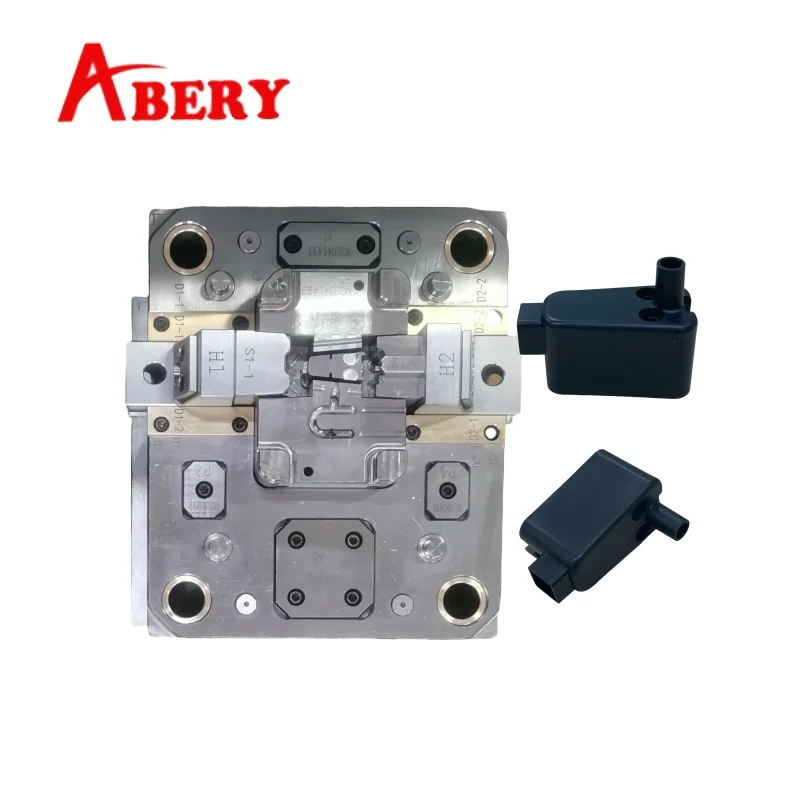

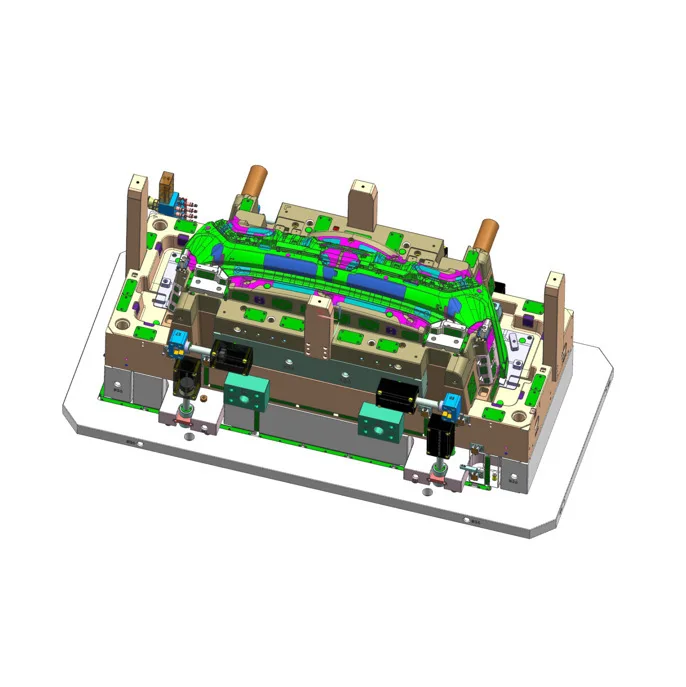

Custom Injection Mould Maker High Precision Plastic Injection Mold

Neway Support Custom Design Moulds & Moulds Export.

Neway Can Also Provide Mould Spare Parts Export, eg: Slider, Inserts, Ejector Pins, etc.

Some Custom Designs Rubber Parts for Reference:

Production Process

NEWAY has complete production chain from R&D, Rapid Prototypes, mould design, mould making, components production, assembling, packing to export.

NEWAY can provide the product design analysis, DFM report (Design for Manufacturability Analysis) for approval and provide 3D printing sample to ensure the design perfect before opening the mold .

NEWAY can provide the product design analysis, DFM report (Design for Manufacturability Analysis) for approval and provide 3D printing sample to ensure the design perfect before opening the mold .

Surface Treatment

The most common used surface treatment are: Matte, Texture (fine texture, rough texture...), Common Polishing, Mirror Polishing, Laser Engraving, Printing, Plating, Brushing, Marbling), etc. You can view below surface pictures for reference:

NEWAY highly welcome custom surface treatment for compression & injection moulds.

The most common used surface treatment are: Matte, Texture (fine texture, rough texture...), Common Polishing, Mirror Polishing, Laser Engraving, Printing, Plating, Brushing, Marbling), etc. You can view below surface pictures for reference:

NEWAY highly welcome custom surface treatment for compression & injection moulds.

Company Profile

Good reviews of customer

Certifications

QC Inspection & Report

NEWAY's mould quality is 100% according to ISO9001 Standard. We seriously take care of the quality control from IQC to OQC, throughout each step of the production.

NEWAY dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

All our materials are purchased from certified suppliers. All materials will be subject to warehousing quality inspection upon arrival. After the pre-production sample is confirmed, the sample will be sealed immediately. prenatal sampling inspection, intrapartum sampling inspection, and postpartum sampling inspection, and the inspection results will be recorded in time. All files are traceable.

Below are some inspection equipment for reference:

NEWAY dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

All our materials are purchased from certified suppliers. All materials will be subject to warehousing quality inspection upon arrival. After the pre-production sample is confirmed, the sample will be sealed immediately. prenatal sampling inspection, intrapartum sampling inspection, and postpartum sampling inspection, and the inspection results will be recorded in time. All files are traceable.

Below are some inspection equipment for reference:

China High Precision Mould Maker Plastic Injection Mold Tool Plastic Injection Mold

And attach the mould testing production samples inspection report for reference:

Packing&Shipping

NEWAY's package for mould: pack in bulk, poly bag, gift box, blister box, or special custom package request according to customers.

All goods shipped by sea are packed with pallets, all goods shipped by express/air are packed with nylon straps. Wooden boxes are used for heavy goods. All cartons have passed the box drop test to ensure that the products received by customers are in good condition.

All goods shipped by sea are packed with pallets, all goods shipped by express/air are packed with nylon straps. Wooden boxes are used for heavy goods. All cartons have passed the box drop test to ensure that the products received by customers are in good condition.

FAQ

Q1:How soon can I get a precise quotation for custom moulds?

A1: Please send us your inquiry by email or Alibaba TM message. Once we confirm the design (Feature details with parameters),

material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it

takes 3-10 days.

1. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for

production.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the mass production.

1. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

2. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D

drawing for you with fair charge.

3. You can also customize Logo on the product surface, package, color box or carton.

4. We also provide assembly service for the OEM parts.

Q5: What is your payment term?

A5: We accept T/T, Paypal, Western Union, L/C, Alibaba Trade Assurance.

A1: Please send us your inquiry by email or Alibaba TM message. Once we confirm the design (Feature details with parameters),

material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it

takes 3-10 days.

1. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for

production.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the mass production.

1. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

2. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D

drawing for you with fair charge.

3. You can also customize Logo on the product surface, package, color box or carton.

4. We also provide assembly service for the OEM parts.

Q5: What is your payment term?

A5: We accept T/T, Paypal, Western Union, L/C, Alibaba Trade Assurance.

Work with Neway your business is in safe and your money is in safe.

If you can dream it, we can build it!

China High Precision Mould Maker Plastic Injection Mold Tool Plastic Injection Mold

Похожие товары

Профессиональная литая алюминиевая форма с ЧПУ для ротационной формовки пластикового Каяка

Металлическая губка с уменьшенным коэффициентом трения

Преобразите свое видение в реальность с помощью наших пластиковых изделий изготовленных на заказ. Премиальные формы обеспечивающие бесшовную доставку

Высокое качество пользовательские пластиковые экструзионные формы

342 541,35 ₽

Литьевые детали для литья под давлением Китай производитель пресс-форм на заказ литьевые пластиковые

5 930,43 ₽

Пластиковая ротационная формовочная форма под заказ сидя на вершине рыболовный каяк

11 860,85 ₽

Пользовательские алюминиевые каноэ rotomolding продукт

Новые поступления

Новинки товаров от производителей по оптовым ценам

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $