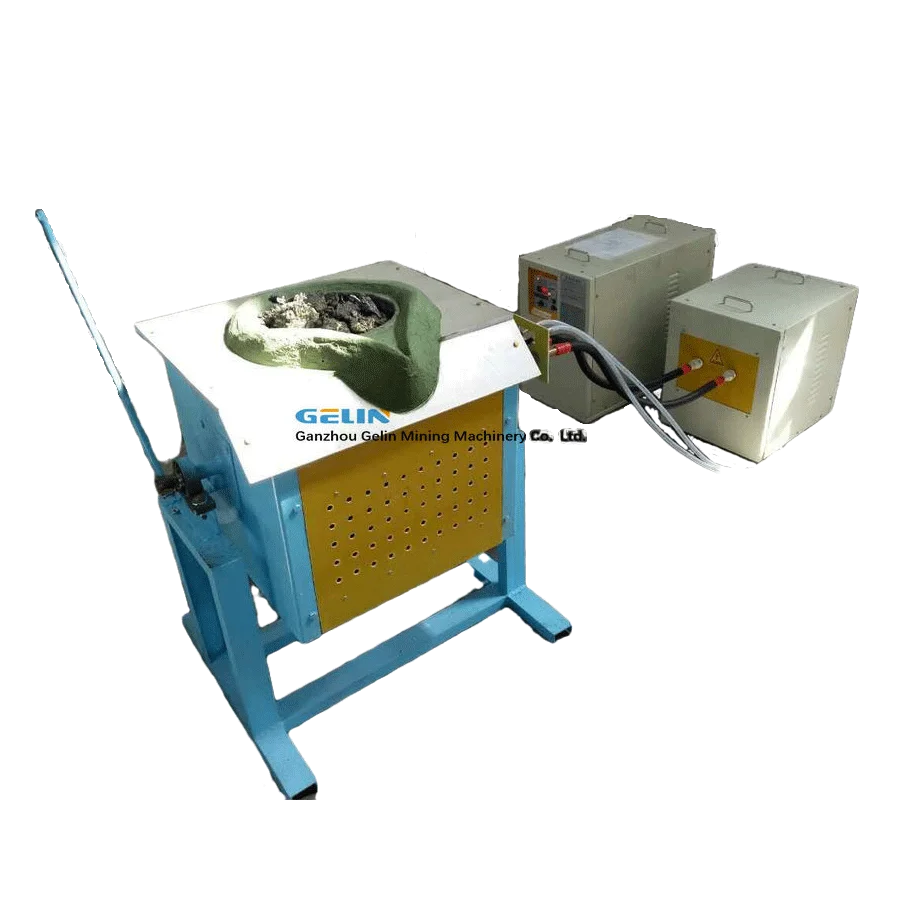

Высокочастотная медная Золотая Серебряная стальная индукционная плавильная печь

- Категория: >>>

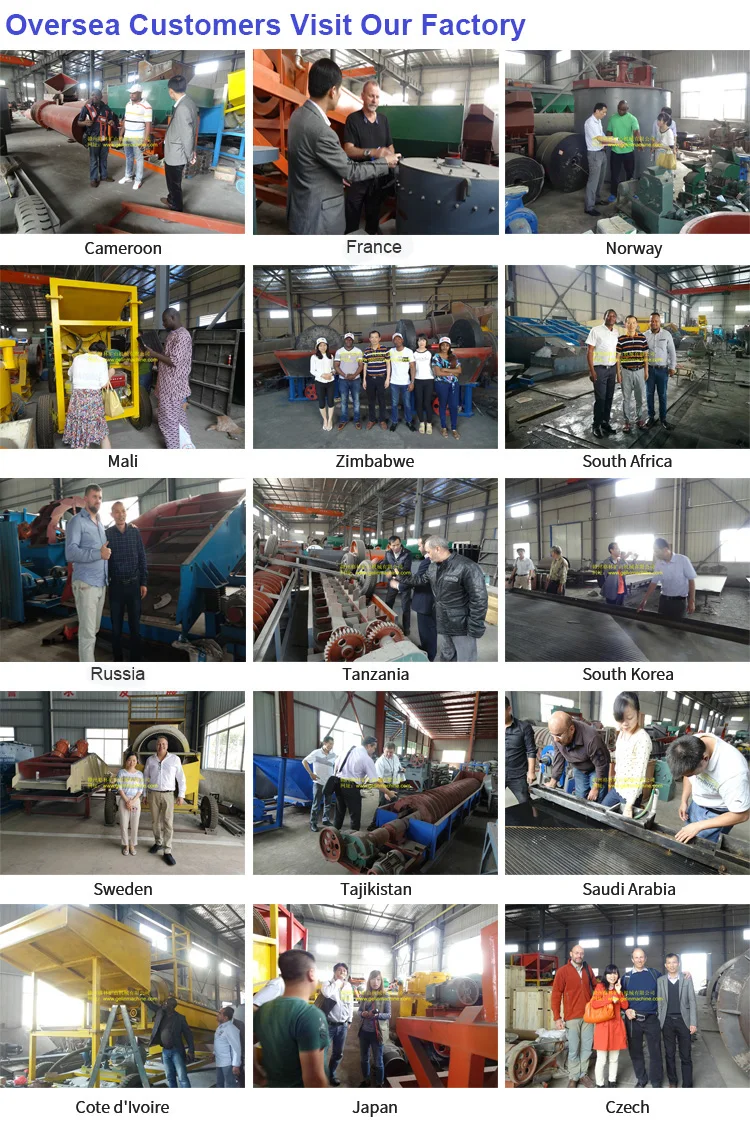

- Поставщик: Ganzhou Gelin Mining Machinery Co. Ltd.Ganzhou Ltd.

Сохранить в закладки 1601291849820:

Описание и отзывы

Характеристики

High Frequency Copper Gold Silver Steel Induction Melting Furnace

IGBT Small Capacity Medium Freguency Induction Melting Furnaces adopts lGBT as the core inverter, it mainly used for melting scrap copper, brass, bronze, aluminum, gold, silver, zinc, iron, steel, stainless steel, aluminum, gold ore,copper ore, other nonferrous metals, ferrous metals and metal alloys.lt is the heat treatment prior to forging, sintering andhot rolling in casting and melting industries.

The melting furnace capacity is normally from 1 Kg to 150 Kg.

Features

1. Fast heating and wide heating

The minimum rate of heating is less than 1 second (rate of heating is available for adjustment and control)

2.Small size and light weight

It has a weight of only several dozens of kilograms, of which, the limited floor space can effectively save the workshop space. Sound operational environment: it is favorable for environmental protection, conservation of energy and safety operation, which is free of any noise, exhaust gas and dust.

3.Multiple type

Have automatic pouring type and push out type and fixed type gold smelting equipment

4.High effectiveness and Save electric

The furnace can save 30% electric than election tubes.and also can save 20% electric than KGPS. The Gold Melting Furnace has such features as uniform heating (it is applicable to adjust the spacing of the inductions coil to ensure the appropriate temperature as required by each part of work piece).fast warming and imited oxic horizon and can quard against any waste after annealing

5.Easy installation and operation

The Gold Melting Furnace can be used once it is connected with power source, inductions coil as well as water supply pipe and rising pipe: it is small in size and light in weight: you can learn to operate it within several minutes.

6.Comprehensive protection

The Gold Melting Furnace has such functions as over voltage. Over current, overheat and water shortage alarm indicationsas well as automatic control and protection.

7.Temperature control

The machine equipped the temperature control system, which can let you control the temperature going at real time.

The Power Supply Features:

1.The Power Unit is based on lGBT, imported from Germany,

2.High power factor, and energy efficient;

3.Heating duty running, 24 hours 100% full loading,

4.Easier and more safe operation comparing with the traditional oil/gas heaters

5.Timing function applied for heating duration setting, adjustable (0.1s-99 9s)

Application

Heat Treatment (surface hardening, quenching, annealing, tempering)

1.Hardening parts of automobile, motorbike, mold, agricultural machinery.

2. Quenching machinery parts, such as: all kinds of gear wheel, chain wheel.

3. Hardening the industrial of machine tool, such as bed guide way of machine tool

4. Heat treatment pliers,spanner, screwdriver, drill, axes, spiker

5. Annealing of various other metal work pieces, such as golf ball head, cue, brass lock, hardware copper fitting, kitchenknife handle, blade, aluminum pan, aluminum pail, aluminum radiator and various aluminum products.

Melting

Non-ferrous and ferrous metals melting

Precious metal melting, like gold, sliver, platinum,etc

Semiconductor material melting

Specialized steel, iron, copper melting

Metal alloy melting, like aluminum alloy, zinc alloy, copper alloy,etc

Product parameter

| Model | 15A | 25A | 35AB | 45AB | 60AB | 80AB | 100AB | 120AB |

| Power(kw) | 2 | 5 | 10 | 15 | 20 | 30 | 45 | 70 |

| Voltage(v) | 220 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| High frequency | 30-50hz | |||||||

| Medium frequency | 1-15hz | |||||||

| Melting weight(kg) | 1-2 | 1-4 | 1-8 | 1-15 | 1-25 | 1-40 | 1-50 | 1-100 |

| Precess time(min) | <5 | <5 | <10 | <15 | <20 | <30 | <40 | <40 |

3.After reaching agreement with client,we start to engineering design,including planning,investigation,data collection, project evaluation etc. and then comes up with design scheme of beneficiation plant construction and working drawings.

A: By TT(Telegraphic Transfer), 100% or 40% Deposit before production and 60% balance payment will be paid off after sending product pictures and before loading from factory.

Q: How long is the guarantee period of your products?

A: Yes, most of our products are produced as required.

A: Yes, engineering consulting is available and we’d like to arrange mineral beneficiation experiment after received your sample and provide the test report.

Похожие товары

Дизельный топливный рельс взрывозащищенный узкий Калибр локомотивная железная дорога Shunting дизельный бесприводный локомотив

Грохот для изоляции угля

Лидер продаж Mgc1.1-6 узкоколейная шахта стационарная используемая для транспортировки угольной шахты

Jkl2 ручная раздвижная быстрая скорость электрическая лебедка 2 тонны малая и средняя

Ручная лебедка с регулируемой ручкой 1 тонна

Электрическая лебедка типа Jk/Jkl/Jm/Jmm/Jmw малой и средней скорости

JKL3 хорошее качество ручная раздвижная электрическая лебедка для шахты или строительства

Новые поступления

Новинки товаров от производителей по оптовым ценам