Высококачественная сборка электродов с сухой Мембраной из китайского завода проточной водородного топливного элемента

- Категория: >>>

- Поставщик: Gatechn New Energy Technology (shanghai) Co. Ltd.Gatechn Ltd.

Сохранить в закладки 1601293166444:

Описание и отзывы

Характеристики

Product Description

Product Presentation

Water Electrolysis Membrane Electrode is a critical component used in the process of water electrolysis. It typically consists of a thin membrane or electrolyte film and two electrodes. Water electrolysis is a chemical reaction in which water is split into hydrogen gas and oxygen gas, and it is a method for producing hydrogen as an energy source.

During the water electrolysis process, the water electrolysis membrane electrode applies electrical energy to water, causing the separation of oxygen ions and hydrogen ions in the water, leading to oxidation-reduction reactions on two electrodes. One electrode (anode) is where the oxidation reaction takes place, while the other electrode (cathode) is where the reduction reaction occurs. Oxygen gas is produced at the anode, and hydrogen gas is generated at the cathode.

Name | Water Electrolysis Membrane Electrode |

Type | Catalyst coated membrane |

Material | PFSA/ Nafion N115 or Nafion N117 |

Cell potential | a) (1A/cm2)=1.67-16.9v |

Cell potential | b) (2A/cm2)=1.91-1.98v |

Cell potential | Customized |

Catalyst Loading | Iridium min loading: 1.85(mg/cm) |

Catalyst Loading | Platinum min loading:0.5(mg/cm) |

Catalyst Loading | Customized |

Reinforcement | PEN or PTFE (Recommend PEN) |

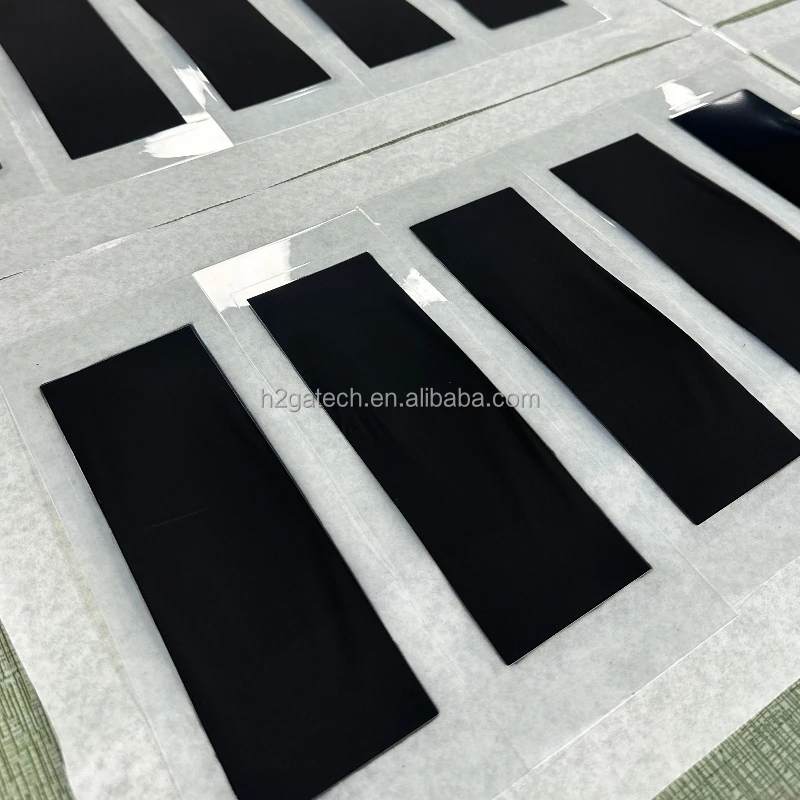

Detailed Images

Product detail drawing

Core component of electrolyzer: Customized Membrane Electrode

MEA (Membrane Electrode Assembly) is composed of diffusion layer, catalyst layer and proton exchange membrane .

MEA (Membrane Electrode Assembly) is composed of diffusion layer, catalyst layer and proton exchange membrane .

Our company's self-developed catalyst offers the following advantages:

High Consistency: Uniform distribution of nanoparticle size.

High Electrochemical Activity: Both ECSA (Electrochemically Active Surface Area) and MA (Mass Activity) are relatively high.

Excellent Durability: The use of high-temperature annealing technology extends the catalyst's lifespan by approximately 30% compared to commercial alloy catalysts

High Consistency: Uniform distribution of nanoparticle size.

High Electrochemical Activity: Both ECSA (Electrochemically Active Surface Area) and MA (Mass Activity) are relatively high.

Excellent Durability: The use of high-temperature annealing technology extends the catalyst's lifespan by approximately 30% compared to commercial alloy catalysts

Hydrogen generation by PEM has four main steps:

1. Water hydrolyzes at anode. (2H2O=4H++4e-+O2)

2. 4H+ pass through the ordered MEA(proton exchange membrane coated with ordered catalyst) to cathode.

3. 3. 4e- electrons transport from anode to cathode through external circuit.

4. Hydrogen generation at cathode. ( 4H++4e-=2H2 )

1. Water hydrolyzes at anode. (2H2O=4H++4e-+O2)

2. 4H+ pass through the ordered MEA(proton exchange membrane coated with ordered catalyst) to cathode.

3. 3. 4e- electrons transport from anode to cathode through external circuit.

4. Hydrogen generation at cathode. ( 4H++4e-=2H2 )

Proton Exchange Membrane

Customized catalyst

Customized Membrane Electrode

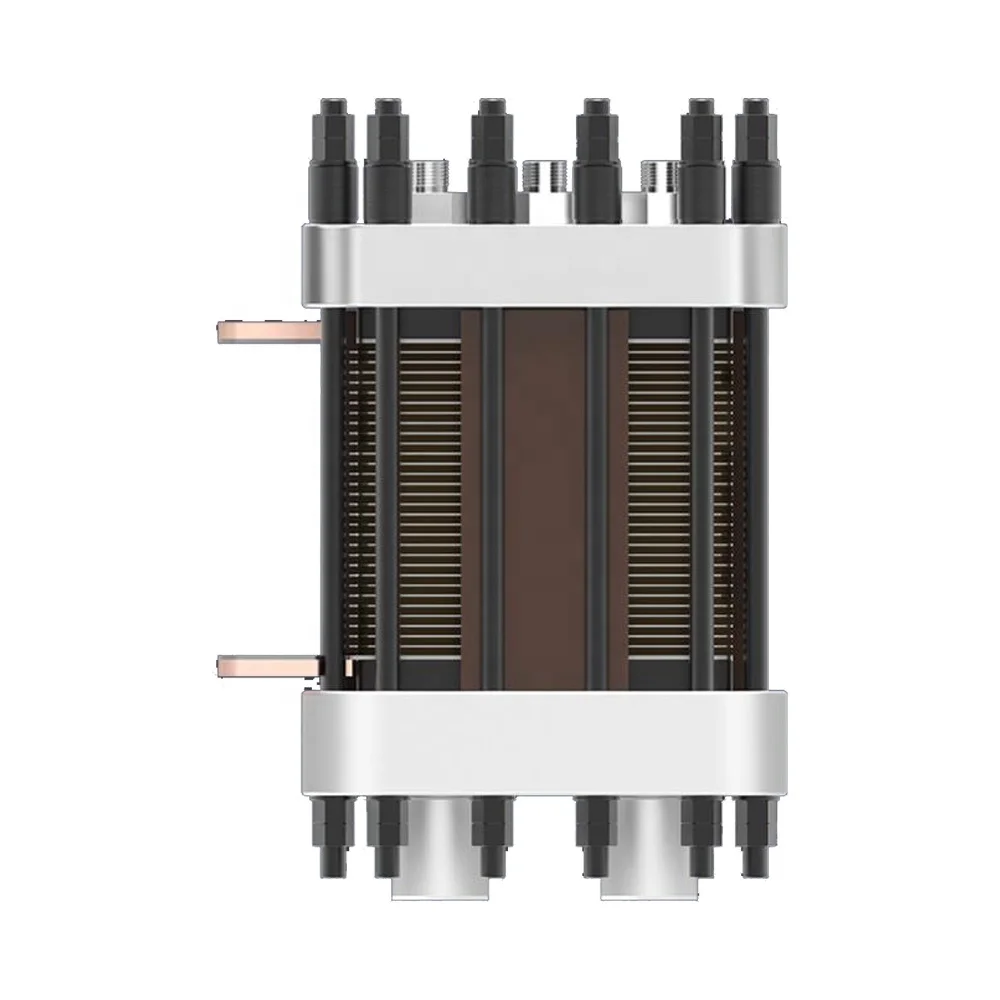

Electrolyzer Structure

PEM Electrolyze Cell

PEM electrolyze is typically composed of end plate, diffusion layer, catalyst layer and proton exchange membrane.

The role of end plate is to fix components, guide current and help distribution of water and gas.

The diffusion layer plays a role as current collector and promote gas-liquid transport.

The role of end plate is to fix components, guide current and help distribution of water and gas.

The diffusion layer plays a role as current collector and promote gas-liquid transport.

H2gatech-Structure diagram of PEM Electrolyze

The core of the catalyst layer is the Triple Phase Boundary (TPB) consisting of catalyst, electron and proton conduction medium, where the electrochemical reactions take place.

For higher hydrogen production rates, a PEM electrolyze is typically stacked with 5 to 100 cells in series.

For higher hydrogen production rates, a PEM electrolyze is typically stacked with 5 to 100 cells in series.

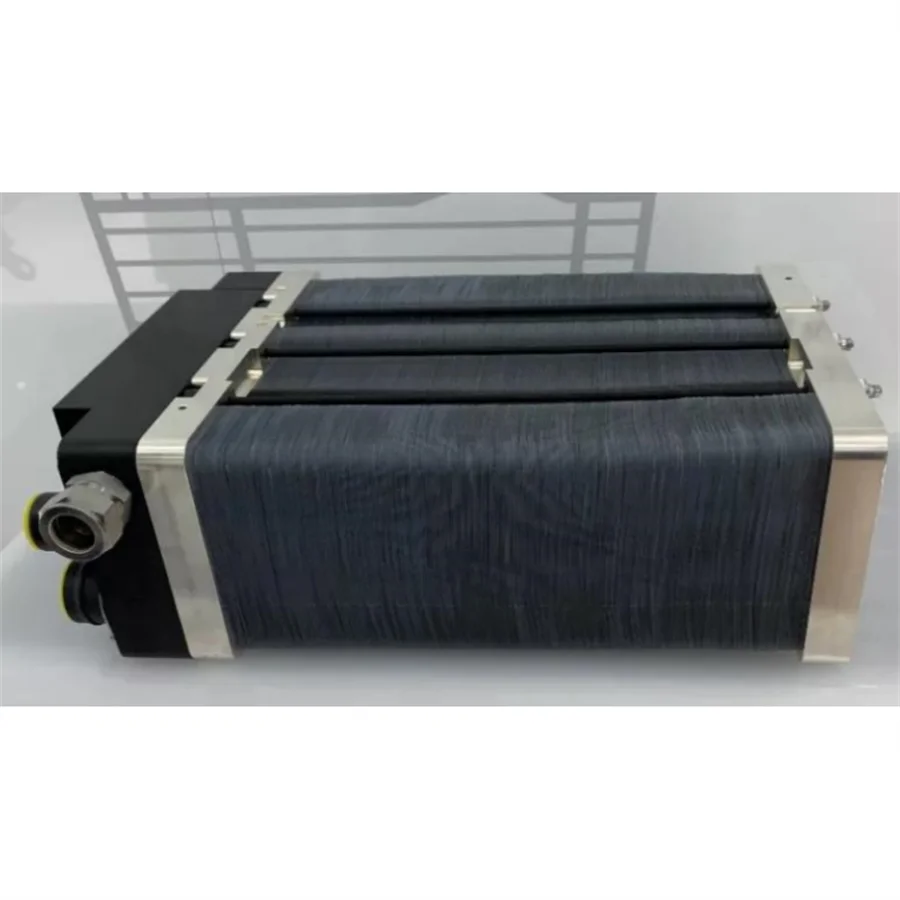

Electrolyzer Assembly

The electrolyzer adopts zero - distance structure to improve assembly efficiency and maintain strong sealing and low contact resistance.

The energy consumption of the electrolyzer has been greatly reduced with the overall efficiency increased from 73% to 84%.

The energy consumption of the electrolyzer has been greatly reduced with the overall efficiency increased from 73% to 84%.

Application showcase

PEM(Proton Exchange Membrane) Electrolyzer

High Efficiency: PEM electrolysis cells typically exhibit higher electrochemical efficiency. Since they only allow protons to pass through while blocking hydroxide ions, they are often more efficient in producing hydrogen gas.

Low Electrolysis Load: Due to their high efficiency, PEM electrolysis cells typically require lower electrolysis loads to produce the same amount of hydrogen, which can reduce the energy cost.

Fast Response: PEM electrolysis cells offer quick startup and response times, making them suitable for applications that require rapid response.

Lower Operating Temperature: PEM electrolysis cells typically operate at lower temperatures, which can reduce energy consumption.

Smaller System Size: Because of their efficiency, PEM electrolysis cells can often be designed with smaller footprints, suitable for applications with limited space.

Low Electrolysis Load: Due to their high efficiency, PEM electrolysis cells typically require lower electrolysis loads to produce the same amount of hydrogen, which can reduce the energy cost.

Fast Response: PEM electrolysis cells offer quick startup and response times, making them suitable for applications that require rapid response.

Lower Operating Temperature: PEM electrolysis cells typically operate at lower temperatures, which can reduce energy consumption.

Smaller System Size: Because of their efficiency, PEM electrolysis cells can often be designed with smaller footprints, suitable for applications with limited space.

Company Introduction

Gatechn New Energy Technology (Shanghai) Co.,Ltd. focuses on the research, development and manufacturing of hydrogen fuel cells, its core materials and key components. It’s a high-tech company and which is dedicated to the Hydrogen Fuel Cell membrane electrode (MEA), hydrogen fuel cell stack system and other related equipment.

The company has developed core materials of hydrogen fuel cell independently, mastered the core technologies of producing various catalysts and membrane electrodes, hydrogen fuel cell stacks and hydrogen fuel cell power systems. The company has developed the whole industrial chain involving hydrogen production and consumption, as well as the application of by-products generated in hydrogen production, etc. the 8 fuel cells production related patents. Moreover, the company has drafted several enterprise standards of "hydrogen fuel cell stack" and "multi-function hydrogen rich machine" production, which have been reviewed and approved by experts.

Our products and services are widely used in many fields such as automotive companies, industrial handling vehicles, communication base stations, unmanned aerial vehicles, standby power supplies, field demonstration emergency power supplies, gas sensors, etc.

The company has developed core materials of hydrogen fuel cell independently, mastered the core technologies of producing various catalysts and membrane electrodes, hydrogen fuel cell stacks and hydrogen fuel cell power systems. The company has developed the whole industrial chain involving hydrogen production and consumption, as well as the application of by-products generated in hydrogen production, etc. the 8 fuel cells production related patents. Moreover, the company has drafted several enterprise standards of "hydrogen fuel cell stack" and "multi-function hydrogen rich machine" production, which have been reviewed and approved by experts.

Our products and services are widely used in many fields such as automotive companies, industrial handling vehicles, communication base stations, unmanned aerial vehicles, standby power supplies, field demonstration emergency power supplies, gas sensors, etc.

We have applied for 25 fuel cell-related patents, with 5 of them granted.

Packing&Shipping

FAQ

When was your company established? What are your advantages?

We were established in 2019 with the participation of many industry experts. The company is headquartered in Shanghai and the new factory is located in Yangzhou, Jiangsu. Our operations team consists of technical experts with more than 20 years of experience in hydrogen fuel cell research and development.

We have established comprehensive cooperative relationships with many well-known domestic universities and research institutes to provide advanced technical knowledge and resource support for hydrogen fuel cell research and development.

We have exported our products to countries and regions including the United States, Canada, Mexico, France, Spain, Chile, South Korea, Malaysia, India, and Taiwan.

What is the minimum order quantity for your products?

One piece

Do you have it in stock?

No, our products need to be ordered and produced.

What is your delivery time?

Delivery time varies from 5 to 20 business days depending on the order.

Do you provide samples?How to get samples?

Samples are available upon placing an order.

What are your payment terms?

Prepayment 100%

We were established in 2019 with the participation of many industry experts. The company is headquartered in Shanghai and the new factory is located in Yangzhou, Jiangsu. Our operations team consists of technical experts with more than 20 years of experience in hydrogen fuel cell research and development.

We have established comprehensive cooperative relationships with many well-known domestic universities and research institutes to provide advanced technical knowledge and resource support for hydrogen fuel cell research and development.

We have exported our products to countries and regions including the United States, Canada, Mexico, France, Spain, Chile, South Korea, Malaysia, India, and Taiwan.

What are your main products?

Hydrogen Fuel Cell membrane electrode (MEA),PEM CCM, hydrogen fuel cell stack system and other related equipment.

Hydrogen Fuel Cell membrane electrode (MEA),PEM CCM, hydrogen fuel cell stack system and other related equipment.

What is the minimum order quantity for your products?

One piece

Do you have it in stock?

No, our products need to be ordered and produced.

What is your delivery time?

Delivery time varies from 5 to 20 business days depending on the order.

Do you provide samples?How to get samples?

Samples are available upon placing an order.

What are your payment terms?

Prepayment 100%

Похожие товары

Лидер продаж электрический велосипед с топливной ячейкой 26 дюймов 500 Вт 700 рама для электрического велосипеда

339 376,80-678 753,60 ₽

Продвинутый генератор топливных элементов 500 Вт мини топливные батареи для продажи

98 419,28-124 438,16 ₽

PEMFC водяное охлаждение Pem топливных элементов генератор водородных 1 кВт/2 кВт/3 кВт/5 кВт Высокая энергоэффективность

1 137 930,42-1 383 865,47 ₽

Высокопроизводительный водородный топливный аккумулятор 6 кВт двигатели на топливных элементах из нержавеющей стали для поездов

15 034 392,24-15 149 780,36 ₽

Электролиз воды генератор водорода PEM протонообменная мембрана CCM

1 148,00 ₽

Лучший выбор 26 км/ч мощный водородный велосипед с генератором баком

129 149,55-132 019,54 ₽

1 нм3 5 10 PEM электролитический водородный аппарат водяной электролиз топливный элемент батареи

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $