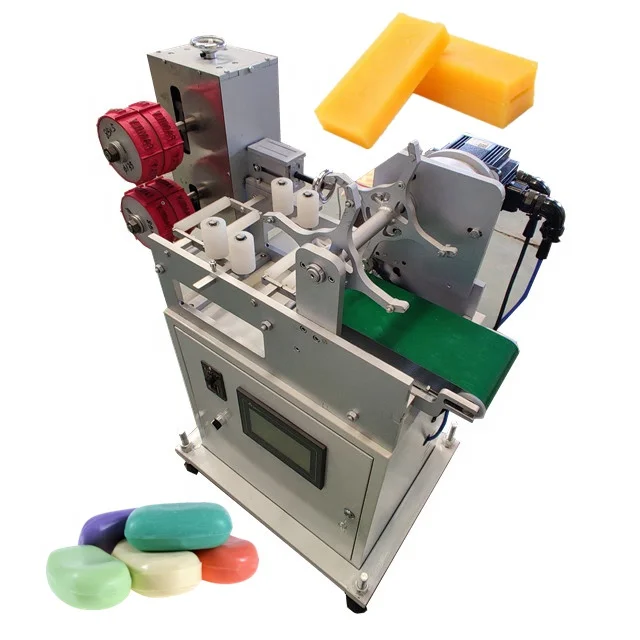

Машина для производства мыла

- Категория: >>>

- Поставщик: Zhengzhou Nora Machinery Equipment Co. Ltd.Zhengzhou Ltd.

Сохранить в закладки 1601293370870:

Описание и отзывы

Характеристики

Products Description

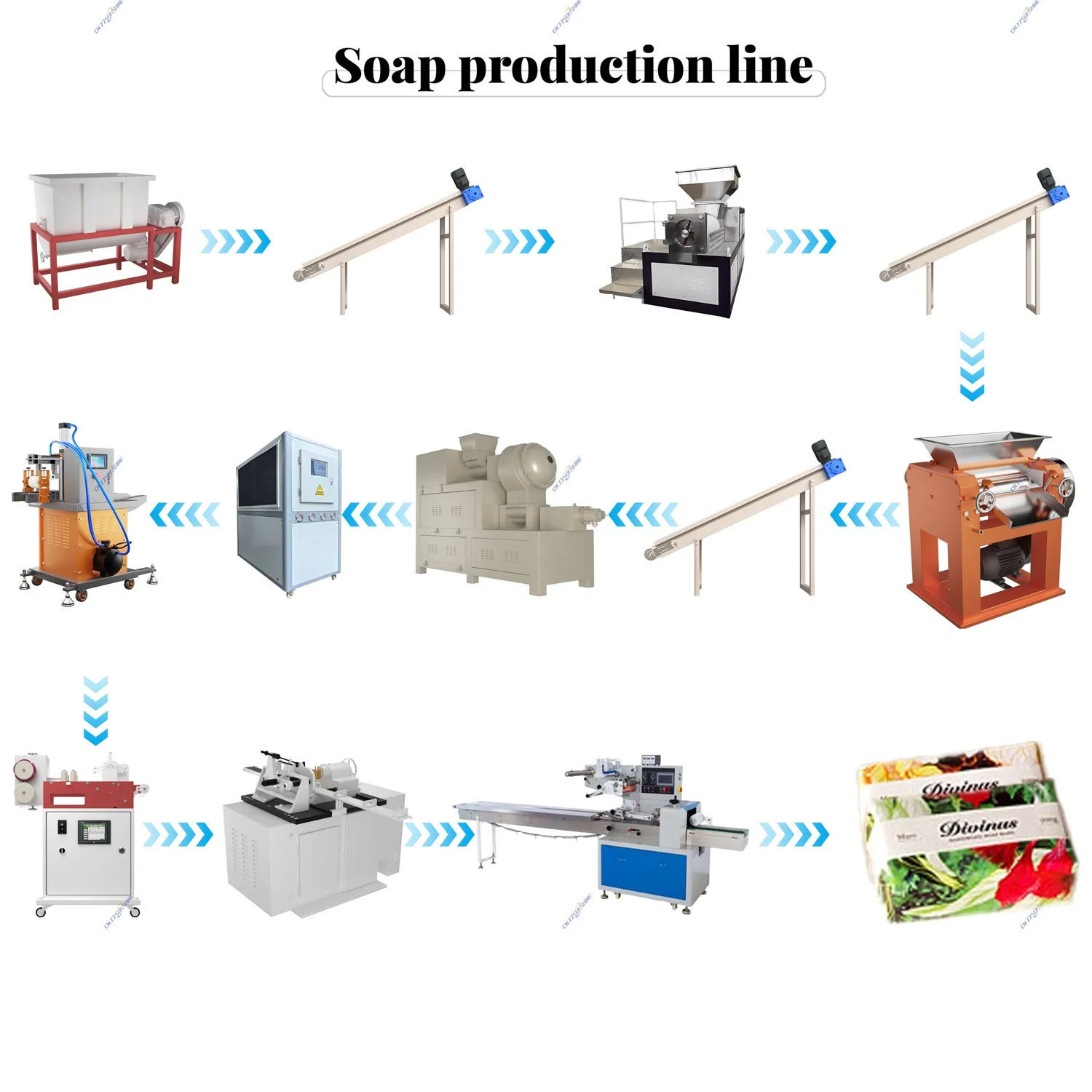

Laundry Soap And Toilet Soap Making Line

This production line is a soap molding production line with soap noodles as raw material and capacity of 50-2000 kg/h. After raw material mixing, grinding, vacuum stripping, electronic roller printing and cutting/Auto Stamping machine.high-grade soap with a fatty acid content of 35-70% can be produced. The production line adopts a double-screw vacuum plodder, which can make the soap structure compact and difficult to crack.

Processing details:

Mixer ---conveyor--- Three roller grinding machine---conveyor---Double-screw vacuum plodder---Soap cutting machine---Packaging machine

Processing details:

Mixer ---conveyor--- Three roller grinding machine---conveyor---Double-screw vacuum plodder---Soap cutting machine---Packaging machine

PRODUCT CONFIGURATION

Laundry Soap production

Toilet Soap Making Line

Large capacity Toilet/bath Soap Line

Video Description

PRODUCT SPECIFICATIONS

Model | NR-100 | NR-300 | NR-500 | NR-1T | NR-2T |

Capacity | 50-100 KG/H | 100-300 KG/H | 300-500 KG/H | 500-1000 KG/H | 1000-2000 KG/H |

Mixer

Role: kinds of auxiliary materials and additives and flavors completely mixed into the granulation, to the formula requirements.Fully mixed soap tablets, soap tablets and a variety of liquid and solid additives can make soap particles and additives fully mixed, stirring effect is full, uniform, color paste, additives completely dissolvedinto the soap.

Three Roll Mill

is used for soap refining. The refining function is achieved by pressing and squeezing force between the adjacent rolls. The main frame is made of high quality stain structure, strong and solid. All gears are precisely manufactured and bathed in oil lubricants for long running life with lower noise, less wearing and better reliability. Rolls are made of special alloy, high hardness, anti-wearing capability.

Double Screw Vacuum Plodder Machine

The double-single-screw vacuuming machine is composed of two single-linker machines, each with its own independent closed-speed transmission system.The machine is made of precision gears. The screw is made of new alloy material or high quality stainless steel, which is corrosion resistant and durable. All other parts in contact with the soap are made of high quality steel. The control part can adopt variable frequency or electromagnetic speed regulation, and the production capacity can be adjusted arbitrarily.

Soap bar cutting machine

This machine can emboss and cut all kinds of laundry soap, fast and accurate.this machine will cut the soap billets from the plodder into long bars to feed into the downstream stamper. For the laundry soap production, a complete set of embossing mechanism can be installed at the front so that the machine can emboss and cut the soaps at the same time to product finished product for downstream packaging. This machine uses PLC for accurate control and HMI for easy operation.

Soap Printer

Printer adopts the best design and technology, driven by servo control and cam system, reliable and high mechanical repeating accuracy. The whole cycle is fully automatic, high speed, low vibration and solid performance.

Soap Stamping Machine

Stamper adopts the best design and technology, driven by servo control and cam system, reliable and high mechanical repeating accuracy. The suction cups pick up soap billet and put it onto the mould, then after forming, pick finished soap bars out to discharge conveyor. The whole cycle is fully automatic, high speed, low vibration and solid performance.

Conveyor

For material transfer between machine

Chiller for Printer

Used to cool down the mold of the printer so that the soap can be released from the mold better

Chiller for plodder

Cool down the temperature of the plodder, so that the machine can run stably and with high quality for a long time

Successful Project

Company Profile

Zhengzhou Nora Machinery Equipment Co.,LTD,established in 2013, specializing in designing and manufacturing the whole set of toilet soap and laundry soap machinery,from soap processing soap making,finishing,packaging and end of line,with a wide range of capacity from 50 kg/h small laboratory line to 2000 kg/h high-speed line.We manufacture all kinds of machinery and Metal products and can meet different customer requirements,such as soap making line, packaging machinery and kinds of machinery,widely used in daily chemical,food,pharmaceutics,chemical industries.We have helped customers in more than 60 countries set up soap business and help customers make a lot of money from it.

Paking and Shipping

FAQ

1.Q: Soap industry production process?

A: Basically, the soap production need 2 steps:

1)Using all kinds of oil&fast as material to produce semi-finished soap noodle;

2)Using semi-product soap noodle to produce end bar soap.

2.Q: What is the floor of the workshop size?

A:Full production line need 35*5m with height 5m.

3.Q:How is the after-sales service?

A:You can send us videos and pictures of the faulty machine, and our engineers will analyze it and provide relevant guidance

online. If the problem cannot be solved, we will send engineers to the local area to

help you solve it.

4.Q:How many days to ship?

A:The production line below 500kg per hour generally takes about 20-40 days, and the production line above 1000kg per hour takes

about two months.

5.Q: What is the formula?

A: Raw material is oil, caustic soda and salt; semi-product is soap noodle, perfume and color.

Accurate formula based on your local market’s request is available after confirmation of order.

A: Basically, the soap production need 2 steps:

1)Using all kinds of oil&fast as material to produce semi-finished soap noodle;

2)Using semi-product soap noodle to produce end bar soap.

2.Q: What is the floor of the workshop size?

A:Full production line need 35*5m with height 5m.

3.Q:How is the after-sales service?

A:You can send us videos and pictures of the faulty machine, and our engineers will analyze it and provide relevant guidance

online. If the problem cannot be solved, we will send engineers to the local area to

help you solve it.

4.Q:How many days to ship?

A:The production line below 500kg per hour generally takes about 20-40 days, and the production line above 1000kg per hour takes

about two months.

5.Q: What is the formula?

A: Raw material is oil, caustic soda and salt; semi-product is soap noodle, perfume and color.

Accurate formula based on your local market’s request is available after confirmation of order.

Похожие товары

Полностью автоматический мини-небольшой смеситель для цельной лапши/машина нарезки большого мыла

965 993,28 ₽

Промышленное твердое мыло экструдер для лапши формовочная машина/машина мыла

Ручная Коммерческая поставка полностью автоматическая мини-линия по производству кускового мыла цена машина для производства небольшого косметического

Оптовая продажа высокоскоростная автоматическая упаковочная подушка для мыла пневматическая пресс-машина малого масштаба

981 504,24 ₽

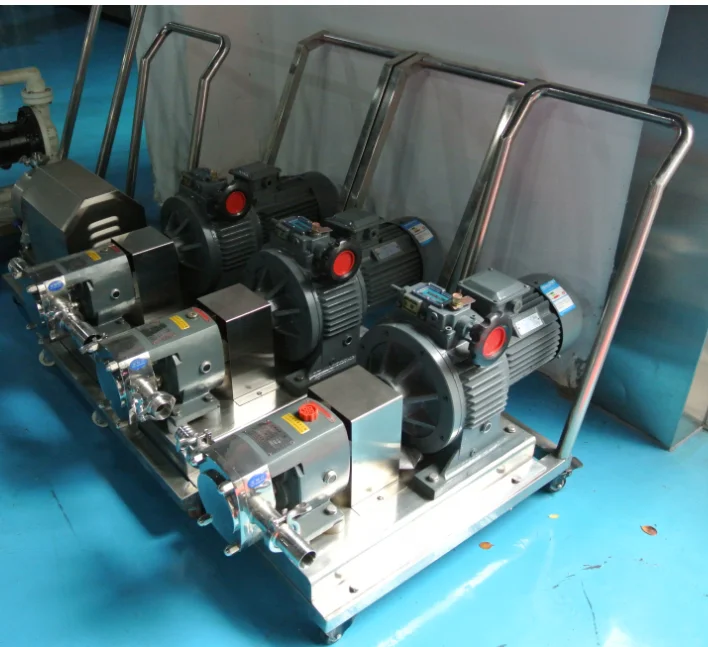

Ротор из нержавеющей стали для сточных вод навоза нефти сырой высоковязкий кулачковый роторный насос

223 691,67 ₽

K2SO4 органический гранулы химических веществ сульфат калия удобрений оборудования

Сульфат калия грануляционное оборудование/K2SO4 оборудование

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $