Волоконно Лазерная режущая насадка D32 M14 H15 однослойная 1 2 5 3 0 4 инструменты головка для резки волокна

- Категория: >>>

- Поставщик: Changzhou Weicheng Welding And Cutting Equipment Manufacturing Co. Ltd.Changzhou Ltd.

Сохранить в закладки 1601293661627:

Описание и отзывы

Характеристики

Products Description

D32 H15 M14( Single)

D32 H15 M14(Double)

High Speed D32 H15 M14(Double)

Single / Double

How to choose?

Single Layer :

Use nitrogen, air as auxiliary gas to cut stainless steel plates, aluminum plates, copper plates, etc.

Double Layers :

Uses oxygen as an auxiliary gas, cutting iron plates, etc.

Remarks:After the double-layer jet gas passes through the inner core, it will undergo secondary expansion.Increase the gas velocity, and then reach the working face through the end hole. This has the advantage of reducing the generation of shock waves,Improve the efficiency of gas participating in cutting, carrying slag and heat.

Our Advantages:

1. High quality raw materials--copper High sensitivity and durability High precision & Fast speed & Multiple sizes

2. High hardness and long service lifeHigh speed cutting, not easy to heat up

3. Smooth cutting with high smoothness One processing molding, smooth inner wall

2. High hardness and long service lifeHigh speed cutting, not easy to heat up

3. Smooth cutting with high smoothness One processing molding, smooth inner wall

Item | Caliber |

D28 Single-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

D28 Double-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

D32 Single-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

D32 Double-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

D28 High speed single-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

D28 High speed double-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

D32 High speed single-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

D32 High speed double-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

SP-S High speed single-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

SP-F Single-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

3D M8 Single-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

3D M8 Double-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

Bullet head single-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

Bullet head double-layer nozzle | 0.8/1.0/1.2/1.3/1.4/1.5/1.6/1.7/1.8/1.9/2.0/2.5/3.0/3.5/4.0/4.5/5.0... |

Other styles | Welcome to inquire |

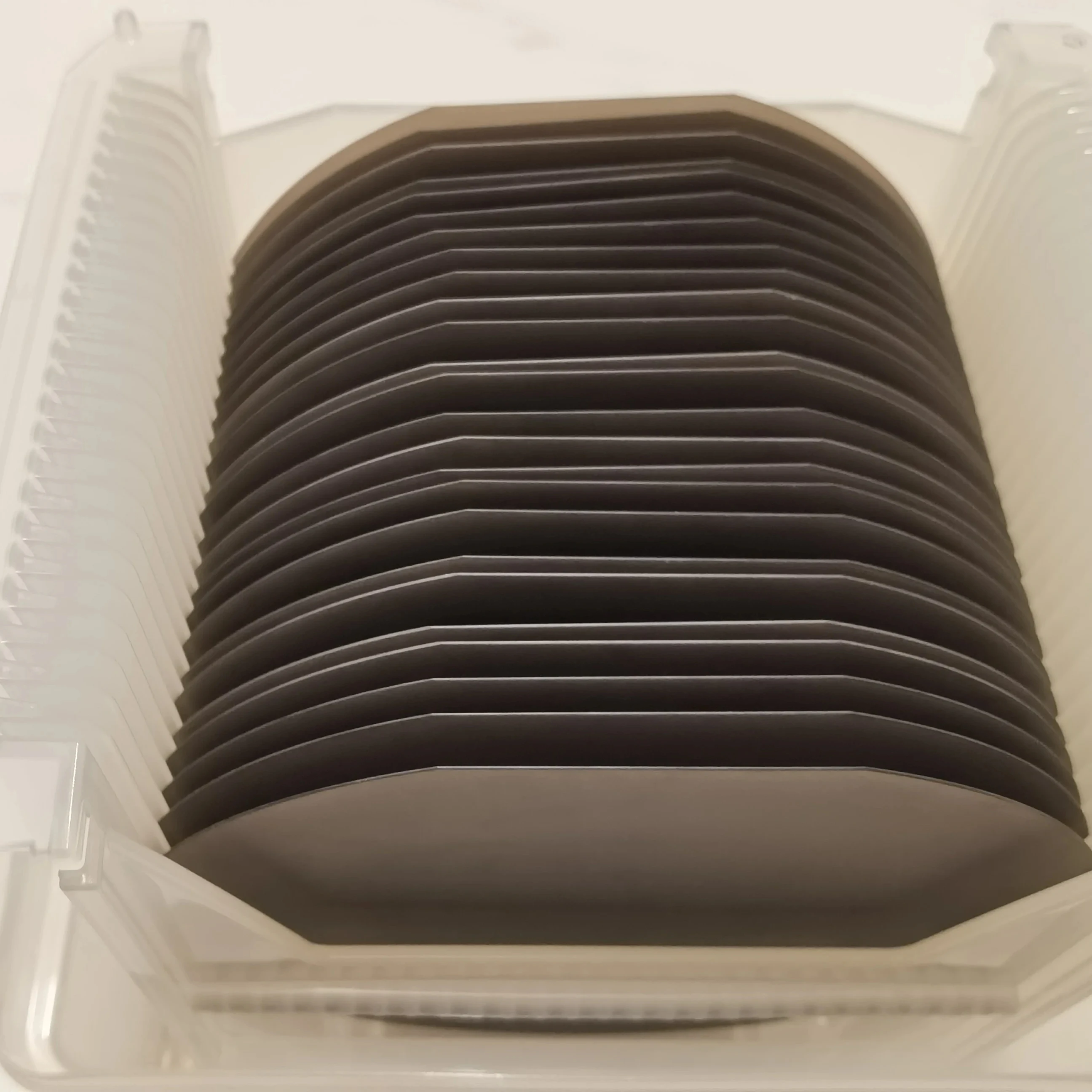

Product packaging

Application

Metal Processing: Laser cutting is particularly prominent in the field of metal processing, mainly used for cutting metal plates,including stainless steel, carbon steel, aluminum, copper, titanium, and titanium alloys. These materials are widely used in industries such as automobile manufacturing, home appliance manufacturing, and electronic component manufacturing. For example, in automobile manufacturing, laser cutting technology can be used for cutting and welding of car bodies, improving production efficiency and product quality. 、

Aerospace: In the aerospace field, laser cutting technology is widely adopted due to its high precision and efficiency. It can be used for the manufacturing of aircraft components, such as cutting and processing wings, fuselages, and other parts, ensuring that the precision and performance of the components meet the requirements.

Mechanical processing: In the field of mechanical processing, laser cutting technology can be utilized for the cutting and processing of components with various complex shapes and structures. Its high precision and speed enhance the efficiency and accuracy of the mechanical processing process.

Electronic equipment: In the manufacturing of electronic equipment, laser cutting technology can be utilized for cutting and processing circuit boards, electronic components, and more. Its precise cutting capability facilitates the miniaturization and integration of electronic devices.

Medical equipment: In the manufacturing of medical equipment, laser cutting technology can be utilized for cutting and processing surgical instruments, medical devices, and other components. Its noiseless and pollution-free characteristics enhance the safety and reliability of medical equipment.

Textiles and Leather: Apart from metallic materials, laser cutting technology can also be applied to cutting non-metallic materials such as textiles and leather. In textile manufacturing, laser cutting can be utilized for cutting cloth of various shapes and patterns. In leather product manufacturing, laser cutting can be employed for cutting and engraving the leather surface, enhancing the aesthetic appeal and added value of the products.

Company Profile

About US

Changzhou Weicheng Welding and Cutting Manufacturer Co.,Ltd. is a manufacturer located in Changzhou, Jiangsu and near Shanghai with good location, convenient transportation and complement resources.We have our own factory and have advanced full automatic equipment to ensure the quality of all products. It strictly follows European & American Design and Use Standard and adopts an advanced management system and strict quality control. Our company has specialized in plasma welding and cutting machineparts for many years.

Our main products include plasma cutting torch head and replacement parts such as plasma electrode, plasma nozzle and so on. We cooperate with manyfamous brands from different countries. Weicheng welding and cutting equipment manufacturing co., LTD specializes in the production and sales of Thermal Dynamics electrode nozzles,Hyperther 1250 electrode nozzles, Hyperther 65A/85A electrode nozzles, Hyperther 85-65, powermax1250 and other welding and cutting accessories.

The company has exquisite skills, perfect quality management system. The company's main product brands are Hyperther, Thermal Dynamics, Trafimet, kjellberg, and so on, the products have plasma electrodes, plasma nozzles, plasma cutting torch,plasma protective cover,plasma shielding cover, domestic plasma cutting machine accessories. Widely used in shipbuilding, steel structure, elevator plant, heavy industry equipment, petrochemical and other industries, in the same industry are in a leading position. In recent years, the customers we have worked with have given a lot of good feedback and evaluation.

Certifications

FAQ

Q1: Can I have a sample for testing?

A: Yes, we can support sample . The sample will be charged reasonably according to the negotiation between us.

Q2: Can I add my logo on the boxes/cartons?

A: Yes, we have a R&D capability and professional & efficient team, OEM and ODM are available from us.

Q3: What are the benefits of being a distributor?

A: Special discount Marketing protection.

Q4: How can you control the quality of products?

A: Yes, we have engineers ready to assist customers with technical support problems, any issues that may arise during the quoting

or installation process, as well as aftermarket support.

Q5: Can we mix items in full container?

A: Yes. We ship our products in bulk, usually 40 Feet High Cube Containers, but 20 feet containers are also acceptable.

Q6:How can i contact with your company?

A: We are always ready to serve you via Email, telephone , skype, whatsapp and alibaba.

Q7: Do you test all your goods before delivery?

A: Yes, we have 100% check before delivery.

A: Yes, we can support sample . The sample will be charged reasonably according to the negotiation between us.

Q2: Can I add my logo on the boxes/cartons?

A: Yes, we have a R&D capability and professional & efficient team, OEM and ODM are available from us.

Q3: What are the benefits of being a distributor?

A: Special discount Marketing protection.

Q4: How can you control the quality of products?

A: Yes, we have engineers ready to assist customers with technical support problems, any issues that may arise during the quoting

or installation process, as well as aftermarket support.

Q5: Can we mix items in full container?

A: Yes. We ship our products in bulk, usually 40 Feet High Cube Containers, but 20 feet containers are also acceptable.

Q6:How can i contact with your company?

A: We are always ready to serve you via Email, telephone , skype, whatsapp and alibaba.

Q7: Do you test all your goods before delivery?

A: Yes, we have 100% check before delivery.

Похожие товары

Ферроэлектрический Хрустальный литиевый ниобат по индивидуальному заказу пьезоэлектрическая пластина

LN LiNbO3 пластинчатый ниобат лития-неорганическое вещество с химической формулой

9 313,48-10 477,66 ₽

Устройство для пилы LiNbO3 кристаллическое химическое стабильное телекоммуникации

9 823,79-10 401,66 ₽

532nm зеленая точка Крест линии лазерный диод модуль 50 мВт

640,31-756,72 ₽

Лазерный модуль 3-5 В зеленая точка 50 МВт 532 нм лазерный диод

640,31-756,72 ₽

Низкая мощность 532nm 50 МВт зеленый лазерный диодный модуль для лазерного света

1 222,40-1 513,44 ₽

Зеленая точка Крест линии 3-5 в 532nm лазерный диод модуль 50 мВт

640,31-756,72 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $