1500 Вт 2000 3000 максимальная Лазерная очистка поверхности металла

- Категория: >>>

- Поставщик: Henan Feiyide Intelligent Equipment Co. Ltd.Henan Ltd.

Сохранить в закладки 1601294549220:

Описание и отзывы

Характеристики

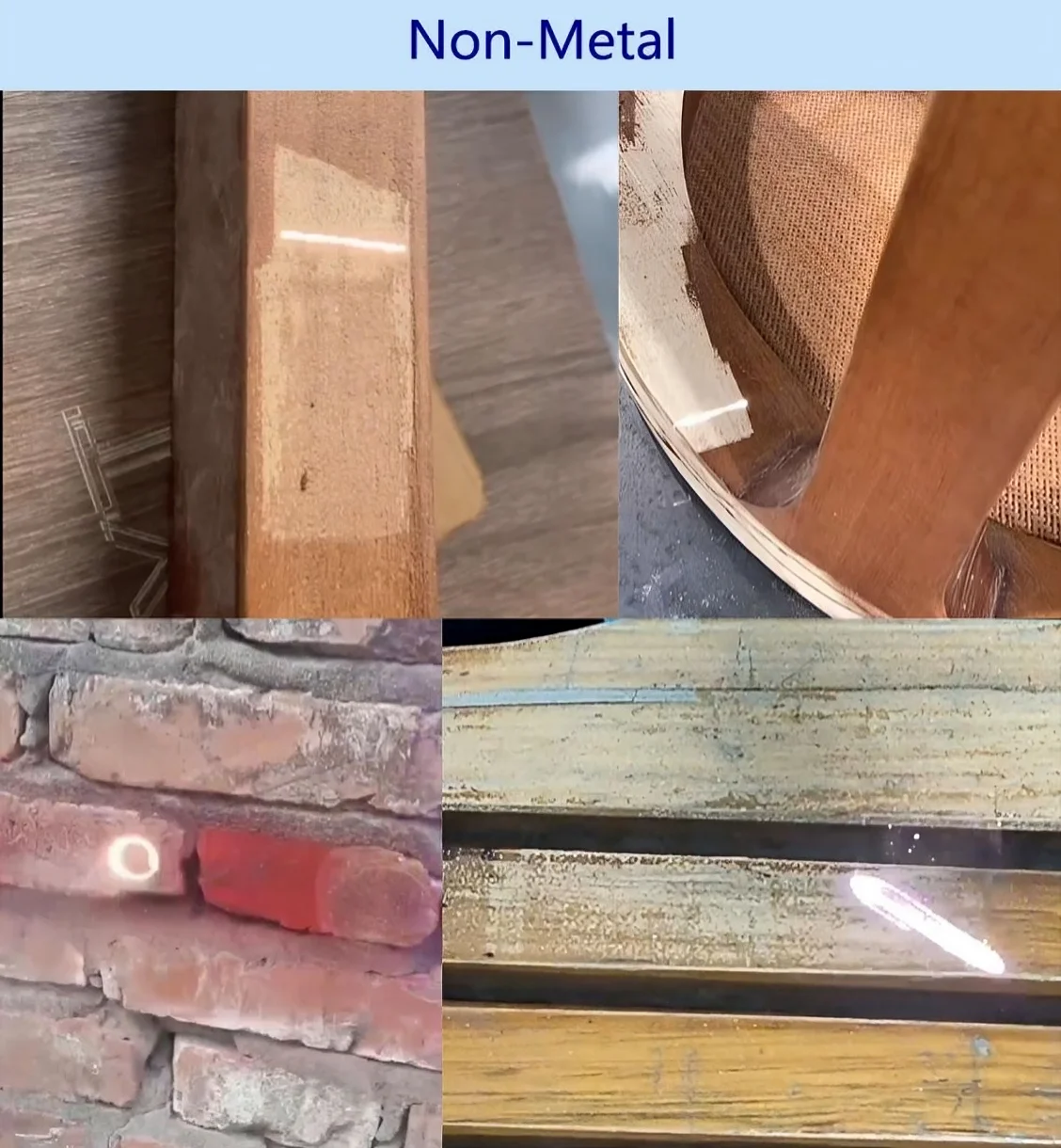

Functions

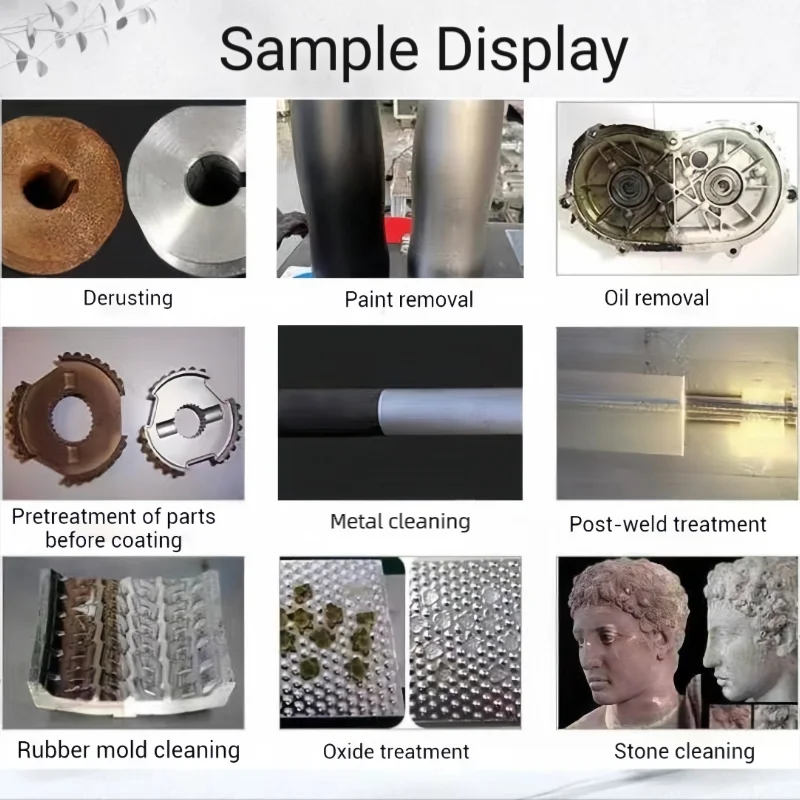

Sample Display

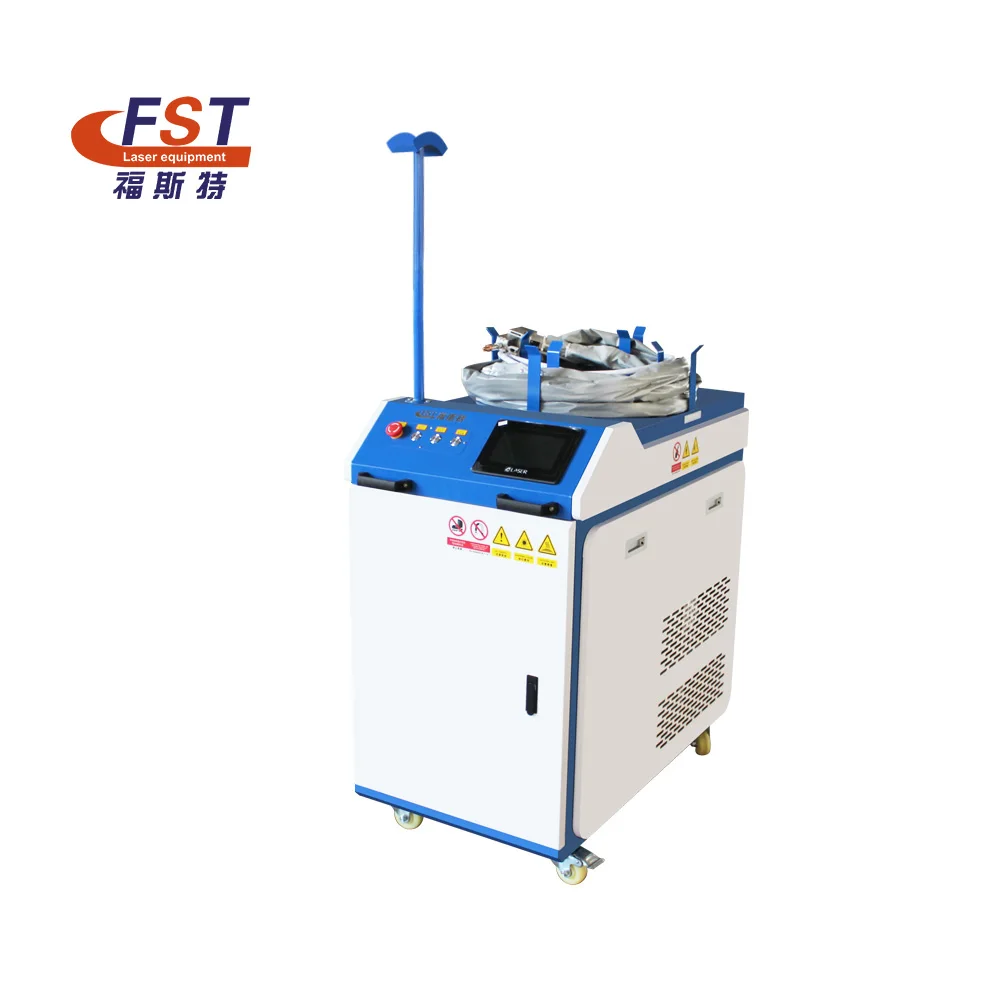

Component Parts

More Than 10 Languages Are Available

Languages: Chinese / Korean /Japanese / German / French / Arabic /Spanish /Portuguese /Vietnamese / Persian / Russian / Thai etc.

Product Catalog

Packing List

Number | Parts | Quantity |

1 | Handheld laser cleaning machine | 1 |

2 | Debugging tools | 1 |

3 | Protective lens D30 * 5 | 5 |

4 | Laser protective glasses | 1 |

5 | Collimating lens D20 * 5 F60 | 1 |

6 | Focus lens D20 * 4.5 F400 | 1 |

7 | Protective gloves | 1 |

Customer Reviews

Physical Goods And Packaging

Inventory

After-Sales Service

FAQ

1、What is the difference between continuous laser cleaning and pulsed laser cleaning?

Difference between continuous laser cleaning and pulsed laser:

1.Energy density: Continuous lasers have a low energy density, while pulsed lasers have a high energy density and very short cleaning times in the nanosecond range, resulting in very little damage to the substrate.

2.Time interval: In continuous mode, the laser continues to irradiate the material for a period of time (usually seconds to minutes) to complete the process. In pulsed mode, the laser is fired multiple times in a short period of time and switches frequencies quickly to remove dirt or contaminants more quickly.

3.Controllability: Because the laser in pulsed mode is more controllable, parameters such as cleaning speed, depth and range can be more easily controlled. In addition, pulsed mode can be used in areas such as fine processing and microanalysis.

4. Scope of use: large area rust removal can choose continuous laser cleaner, fast speed and good results at a more favorable price; the need not to damage the surface of the substrate can choose.

2、What are the differences in application scenarios between continuous and pulsed laser cleaners?

Continuous laser cleaner: Suitable for cleaning light dirt attached to the surface, such as paint, grease, dust, etc. It is suitable for cleaning large flat surfaces. Pulsed laser cleaning machine: Suitable for cleaning dirt that is more difficult to clean, such as oxidized layers, coatings, welding slag, etc. It is more suitable for fine parts or cleaning tasks that require high surface quality. Overall, continuous laser cleaners are suitable for large area cleaning, while pulsed laser cleaners are suitable for the cleaning of more difficult dirt and fine parts.

3、Why are pulsed laser cleaners less powerful and more expensive?

Although the average power of pulsed laser is low, its peak power may be higher, the peak power of pulsed laser with an average power of 14w can reach up to 7000w. Pulsed lasers can be adjusted with many parameters, and the application scenarios are more abundant.

4、What power is best for me?

Functionally, all models offer the same features, with the biggest difference being the power output. Generally speaking, the higher the output power, the shorter the working time required to clean the surface. So, if you can afford it, choose a higher output power:if you don't need the machine often, choose a lower power.

5、Why Fiber Laser Cleaners Market share is large?

Excimer lasers cost about 20,000 for 5 watts, and if you use them for laser cleaning, you need at least 200 watts or more, which is too high. And now there is no production of such high power excimer laser. Carbon dioxide laser in addition to the price reasons, more importantly, carbon dioxide laser light path can not use fiber optic line to conduct, limiting its application scenarios. So at present the laser cleaning field can choose only fiber laser, fiber laser is cheap, small and exquisite, can be transmitted by fiber optic line, flexible operation, long life!

6、Is FYID-feiyide Laser's laser cleaner a good solution for me?

Our aim has never been to sell you laser equipment that is of no practical use to you, if you need it, we are always there. 1.If you still want to know more about laser cleaning machine 2. Your team wants a better working environment. 3. You are willing to innovate and want to do a better job. 4. You want to get long-term economic benefits

Похожие товары

Новый стиль 1000 Вт 1500 2000 3000 ручная машина для непрерывной волоконной лазерной очистки удаления ржавчины и резки краски сварка

3 100,00-3 200,00 $

Аппарат для лазерной очистки 2000 Вт

2000 Вт CW волоконно-лазерная машина для очистки

7 217,00 $

1500 Вт 2000 3000 6000 волоконно-лазерный сварочный аппарат Автоматическая аккумуляторная лазерная сварочная машина

Заводская распродажа лазерная Очистительная Машина 2000 Вт/1500 Вт с удалением ржавчины металла

1000 Вт 2000 3000 импульсная волоконная ручная Лазерная Очистительная Машина для удаления краски и ржавчины

3 400,00 $

Высокая точность 300 Вт высокой мощности импульсный лазерный очиститель

9 540,00-9 940,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $