Автоматическая замечательная жареная пищевая линия для производства продуктов

- Категория: >>>

- Поставщик: Jinan Kelid Machinery Co. Ltd.Jinan Ltd.

Сохранить в закладки 1601294572402:

Описание и отзывы

Характеристики

Automatic Remarkable Fried Bugles Sala Chips Rice Crust Snacks Food Processing Production Line

Fried chips production line adopts single screw extruder, twin-screw extruder, or secondary extrusion extruder to make different shapes of pellet chips with different molds and different cutting machines.

Raw material mixing, extrusion, cutting, drying and baking, frying, flavoring, and packaging are all in line with automatic production, with a high level of automation.

Due to different frying requirements (Like time and temperature) of fried snacks, there are continuous frying machine and the batch frying machine can be chosen. In addition, auxiliary machines like oil tank, oil filter, etc. are all provided.

Fried chips production line has a wide range of raw materials, mainly adopts wheat flour, corn starch, potato starch, etc. It can produce different shapes of 2D/ 3D pellet snacks by changing the different molds or cutting machines, like onion rings, crispy corners, salad strips, salad chips, tortilla chips, casserole, tube shape, flower shape, pillow shape, and so on. After frying and puffing, the fried chips snack is crispy and not greasy which is popular with consumers.

Machine List:

Mixer— Screw conveyor— Extruder— Cutter— Hoister— Fryer— Vibrating deoiling machine— Hoister— Flavor roller— Cooling conveyor— Elevator— Packing machine

Jinan Kelid Machinery Co, Ltd. is a professional supplier of food processing machines. Our company's Motto is:"Technology Makes Easy". We offer to cooperate with our customers for mutual and beneficial development. All Inquiries are welcome.

We are located in Jinan, the Capital of Shandong Province. Jinan Kelid Machinery C., Ltd is vested with many staffs with many years of experience in supplying the food processing machines. Our main products line include Fried chips production line, Cheetos Kurkure Nik Naks Corn Curls making machine, puffed Snacks making machine, pet food making machine ,fish feed making machine, modified starch making machine, soya Protein/ soya meat processing machines, industrial microwave oven, packaging machines, rice cake machine etc... Most importantly, we also provide formulas, technology supports, machine inspection service, etc.

Cooperating with different manufacturers and research centers, we provide the food processing machines with outstanding quality. We have a group of experienced experts and outstanding engineers who do provide the professional service delivery and installation. Based on the clients specific requirement, we also design and produce the machines to order. We have through the years established good working relationship with some reputable organizations both at home and abroad with outstanding good will..

1.The raw material has a wider adaptability and can be adapted to high viscosity, low viscosity, high oil content, high moisture or viscous, oily raw materials.

2. The internal and external quality of the product is good, it can achieve a very good homogeneous state and make the molecular structure of the material evenly arranged

3.Low production cost, less waste at startup, less waste of water, less man-power, high heat transfer efficiency, high yield and low cost of accessories.

4. The effect of curing and homogenization is good, the starch curing degree can reach more than 95%, which makes the processed products easy to digest and absorb.

5. High hygienic quality: The extrusion process can kill harmful microorganisms and parasites in the raw materials, improve the hygienic quality of food, and reduce the risk of diseases.

6. Good stability: The food after extrusion treatment has good stability and shelf life, which can ensure the quality and taste of the food.

7. Easy To Operate: The operation process is simple, stable, safe and friendly.

Model | Pellet Chips Line |

Capacity(kg/h) | 80-120 |

Installed power (kw) | 80 |

Power consumption (kw) | 56 |

Dimension (m) | 25*2*2.5 |

1. Help client to design the factory and offer professional advice and engineering drawing for the factory layout.

2. Report production progress regularly.

3. If the client can’t come to check the machine before delivery, Kelid helps the client check and make a testing report to show the details.

4. Provide user manual, factory inspection form, product certificate.

5. Provide 1-2 engineers to the client's factory for the installation and first-line workers' training.

6. After the installation, our engineer will assist you in on-site commissioning and personnel training (Training includes: equipment operation methods, precautions for use, equipment maintenance, etc.

7. Provide 13 months warranty and lifelong service.

Похожие товары

2021 Корейская машина для выпечки риса

Аппарат для снэков из нержавеющей стали профессиональный мини-креп-аппарат антипригарный Электрический Креп-аппарат

TENSHINE промышленный угольный гриль для кур TFS-24C автоматический портативный барбекю машина с CE

Новейшее и самое популярное автоматическое оборудование для конфетного магазина упаковочной машиной типа флоу-пак

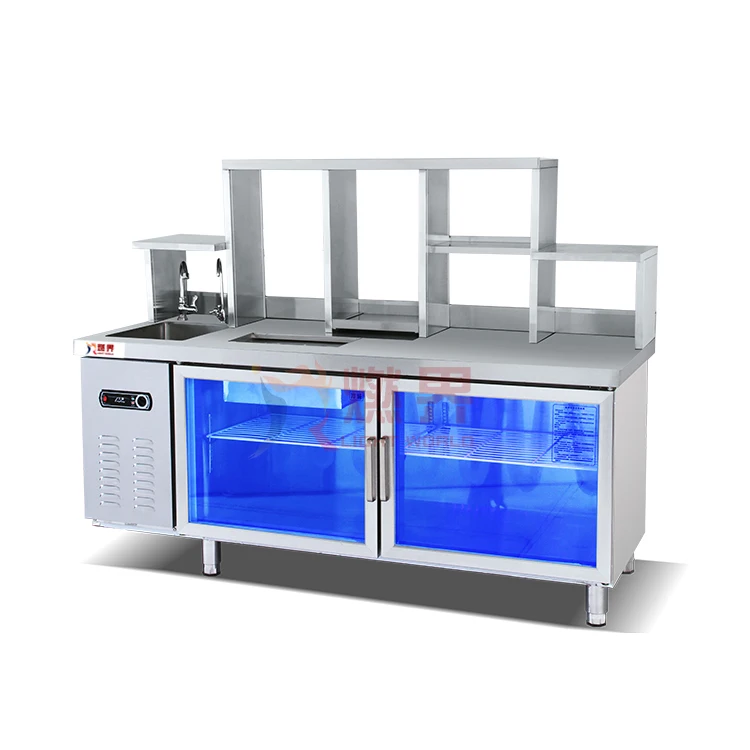

Чайная станция для кофе рабочий стол барная стойка из нержавеющей стали молока и чая

Оптовые продажи Китай хлебобулочные детские игровые шары пластиковый шар делая машину

Формовочная машина для макаронных изделий

Новые поступления

Новинки товаров от производителей по оптовым ценам