Лазерная резка по металлу

- Категория: >>>

- Поставщик: Wuhan Golden Laser Co. Ltd.Wuhan Ltd.

Сохранить в закладки 1601295206919:

Описание и отзывы

Характеристики

Product Application

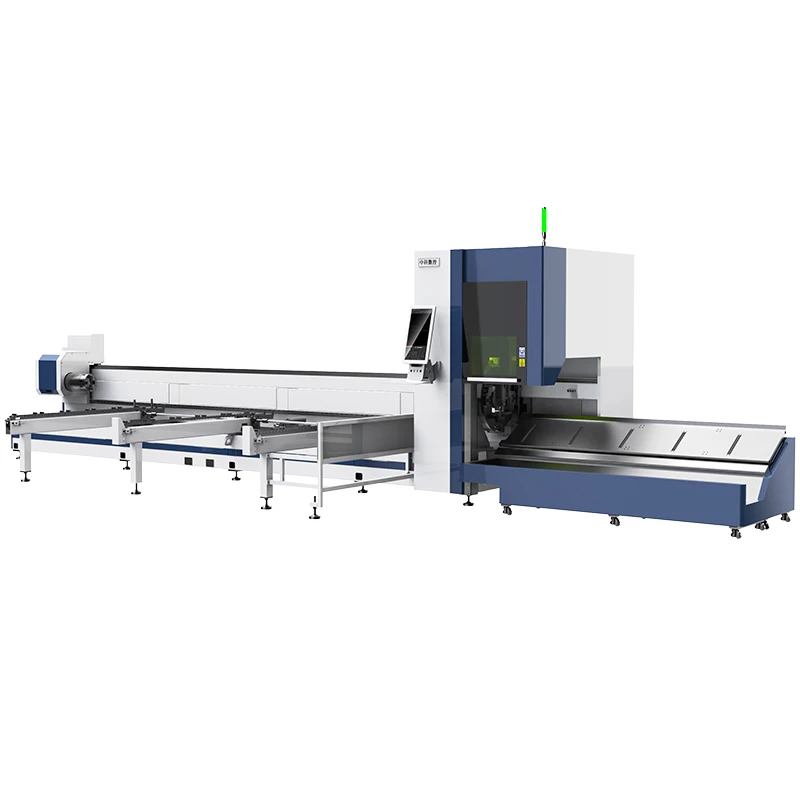

• Tubes up to ∅ 4.72″ (120 mm)

• Automatic feeding achieves continuous processing

• High efficiency, maximum acceleration up to 1.5G

• Wide processing range, such as round, rectangular, elliptical, and special-shaped tubes.

• Cost-effective. Compact and integrated design, with a smaller equipment footprint, and lower shipping cost.

Applicable Industry

Furniture, medical device, fitness equipment, oil exploration, display shelf, farm machinery, bridge, boating, structure parts, etc

Applicable Material

Stainless steel , carbon steel, galvanized steel, brass, alloy, copper, iron, titanium, etc

Applicable Types of Pipe

Specially for round, square, rectangular, oval, waist round tube and other metal pipes

SPECIFICATIONS FOR S12CA | ||||

Model number | S12CM | P3080A-3D | ||

Fiber laser source | Max/ IPG/ Raycus fiber laser resonator | |||

Laser power | 1500W 2000W 3000W | |||

CNC controller | FSCUT3000DEM | |||

Laser head | Raytools | |||

Type of tube | Round, square, rectangular, oval, channel steel, I-beam, profile, etc. | |||

Pipe length | 6000mm | |||

pipe size | Φ10mm-120 mm ; Square tube 10mm*10mm- 120mm*120mm | |||

Position accuracy | 0.05mm | |||

Max rotate speed | Max 150r/min | |||

Cut Acceleration | 1.5g | |||

Round tube processing range: diameter 10-120mm

Square tube processing range: 10×10-120mm×120mm

Wuhan Golden Laser Co., Ltd. was established in 2005 and listed on the Shenzhen Stock Market in 2011. It is a digital technology commercial application solution provider. The "Golden Laser Intelligent Park" project has been completed and is in production. It is divided into an industrial intelligent manufacturing park and a business intelligence application park, covering over 50,000

square meters. The industrial intelligent manufacturing park is mainly engaged in:

1. the manufacture of intelligent equipment

such as lasers, automation, robots, and industrial chain-supporting

2. the business intelligence application park is mainly

engaged in developing 3D digital technology such as Golden Laser Digital Headquarters, 3D digital display, holographic display, various AR/VR, 3D printing, Internet platform operations, intelligent unmanned retail terminal, etc. Golden Laser has significantly grown in metal sheet cutting, tube cutting, and laser welding.

What laser machines does Golden Laser manufacture?

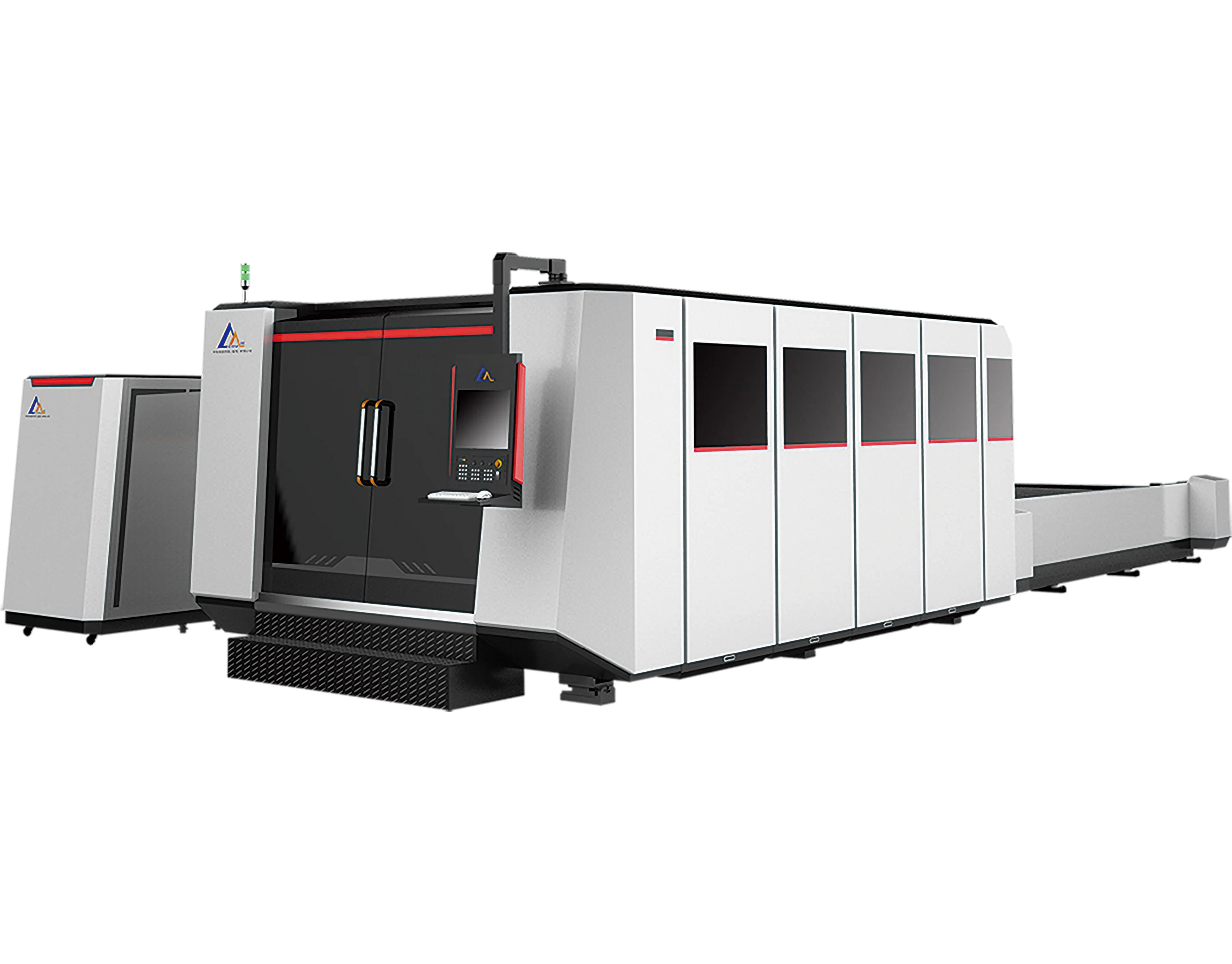

● Fiber Laser Cutting Machine for Sheet Metal

● 5 Series of Fiber Laser Cutting Machines for Tube/ Pipe

● Multifunctional Fiber Laser Cutting Machine for Sheet and Tube

● Customized Laser Solution

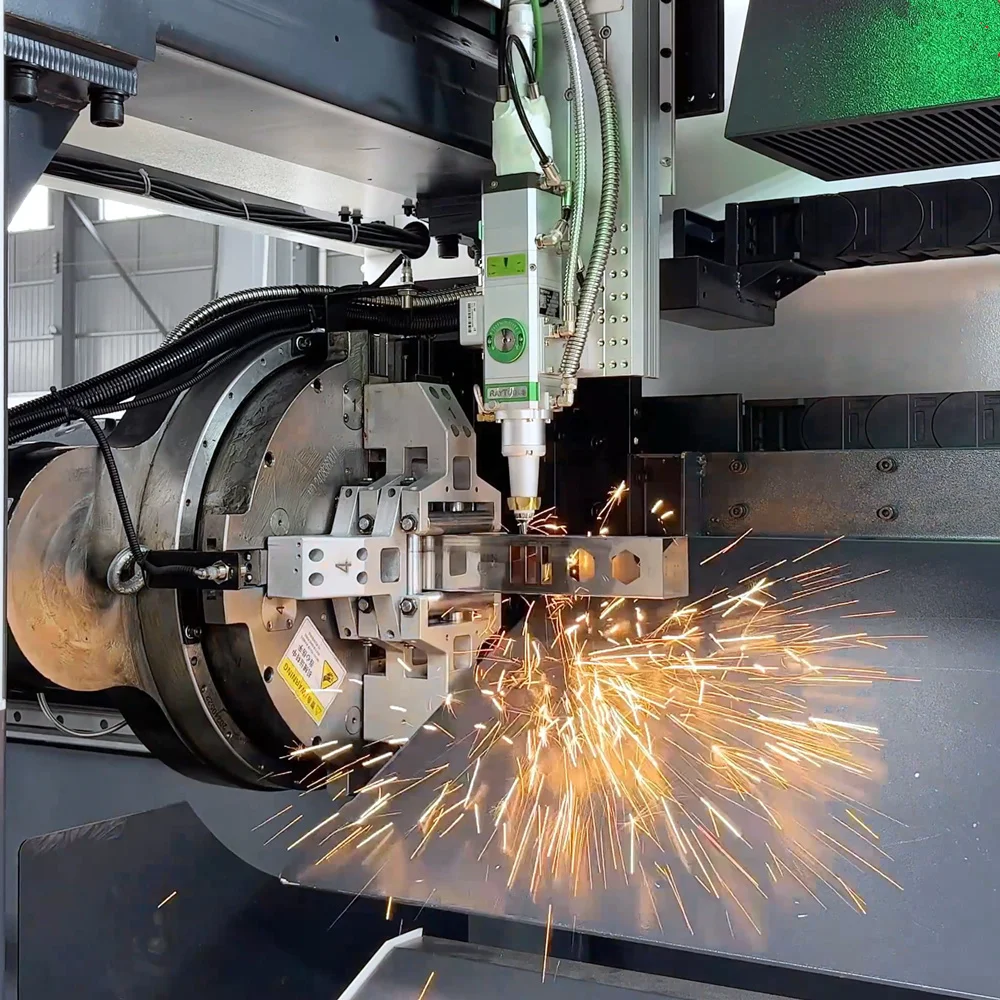

● 3D Robot Laser Cutting Machine

● 3D Robot Laser Welding Machine

● Handheld Laser Welding Machine

Golden Laser has achieved a vast response worldwide, and its equipment is exported to more than 120 countries and regions on five continents. It has signed agency cooperation agreements with more than 50 countries, including the United States, Germany, Britain, France, South Korea, India, Australia, South Africa, Taiwan, Hungary, Mexico, Colombia, Russia, and Spain.

Golden Laser Europe B.V., as a subsidiary of Wuhan Golden Laser Co., Ltd, was established in the

Netherlands with a technical service center to provide laser service throughout Europe. Official website: www.goldenlasereurope.com

Address: Magnesiumstraat 19, 6031 RV Nederweert, Netherlands.

1.Whole film packaging machine;

2.Anti-collision package edge;

3.Fumigation-free plywood wooden box

3. What is the size and thickness of the material?

4. What is your application industry? / What is your final product?

5. Your company name, website, Email, Tel (WA...)?

Похожие товары

SENFENG высокое качество 2 года гарантии напрямую с фабрики питания ЧПУ металла волокно лазерной резки 3015AM

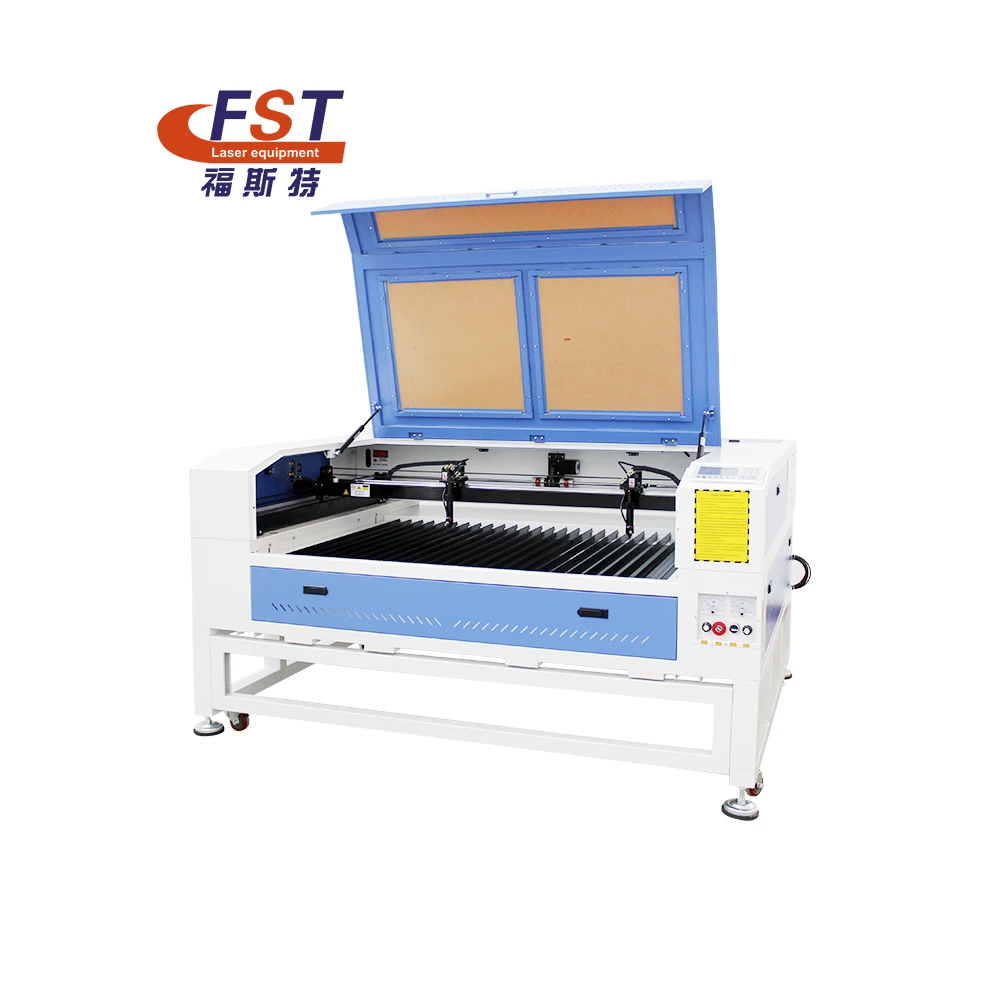

Ляочэн FST CO2 станок для лазерной резки 60 Вт 80 100 деревянная мебель лазерная гравировка машина 1390 1610 неметаллических гравер

Волоконно-лазерная резка машина из нержавеющей стали для лазерной резки

Новая модель GT-1390 Размер 150 Вт лазерной резки в Мексике

Сертификат Ce изготовленные на заказ автоматические гайкоразрезающие станки

Машина для лазерной резки ткани GoldenLaser печати хлопчатобумажной

EdgeMaster система полировки стеклянных краев

Новые поступления

Новинки товаров от производителей по оптовым ценам