Горячая Распродажа мини битум Асфальт завод цена

- Категория: >>>

- Поставщик: Henan Sinoroader Heavy Industry CorporationHenan Corporation

Сохранить в закладки 1601307960114:

Описание и отзывы

Характеристики

80 t/h Capacity LB1000 Asphalt mixer Batching Plant

Features

Staionary asphalt batching plant is a stationary hot mix asphalt plant developed and manufactured by sinoroader in accordance with the needs of the market after absorbing the international advanced technology. The mixing plant adopts a modular structure, fast transportation and convenient installation, compact structure, small cover area and high cost performance. The total installed power of the device is low, saving energy, can create considerable economic benefits for the user. The plant features accurate measurement, simple operation and stable performance which fully meets the requirements of highway construction and maintenance.

1. Skirt type feeding belt to ensure more stable and reliable feeding.

2. Plate chain type hot aggregate and powder elevator to extend its service life.

3. The world's most advanced pulse bag dust collector reduces emission to be below 20mg/Nm3, which meets the international environmental standard.

4. Optimized design, while using high energy conversion rate hardened reducer, energy efficient.

5. Plants pass through the EU, CE certification and GOST(Russian), which are in full compliance with U.S. and European markets for quality, energy conservation, environmental protection and safety requirements.

| Model | Capacity(Standard Conditions) | Mixer Capacity | Dust Remove Effect | Total Power | Fuel Consumption | Measurement Accuracy | |

| Fuel Oil | Fuel Coal | ||||||

| LB700 | 60t/h | 750 kg | ≤20 mg/Nm³ | 178kW | 5.5-7 kg/t | 10kg/t | Aggregate: ±0.5% Filler: ±0.25% Bitumen: ±0.25% |

| LB1000 | 80t/h | 1000 kg | ≤20 mg/Nm³ | 285kW | 5.5-7 kg/t | 10kg/t | |

| LB1200 | 100t/h | 1200 kg | ≤20 mg/Nm³ | 316kW | 5.5-7 kg/t | 10kg/t | |

| LB1500 | 120t/h | 1500 kg | ≤20 mg/Nm³ | 380kW | 5.5-7 kg/t | 10kg/t | |

| LB2000 | 160t/h | 2000 kg | ≤20 mg/Nm³ | 470kW | 5.5-7 kg/t | 10kg/t | |

| LB2500 | 200t/h | 2500 kg | ≤20 mg/Nm³ | 547kW | 5.5-7 kg/t | 10kg/t | |

| LB3000 | 240t/h | 3000 kg | ≤20 mg/Nm³ | 700kW | 5.5-7 kg/t | 10kg/t | |

| LB4000 | 300t/h | 4000 kg | ≤20 mg/Nm³ | 870kW | 5.5-7 kg/t | 10kg/t | |

| LB5000 | 400t/h | 5000 kg | ≤20 mg/Nm³ | 960kW | 5.5-7 kg/t | 10kg/t | |

click here to send inquiry,engineer will disscus about the asphalt plant details

Main Structure

1. Cold Aggregate Feeding System

- The belt feeder use frequency conversion speed control, speed adjust rang is wide, high working efficiency.

- Every hopper discharge gate have material shortage alarming device, if material shortage or material arching, it will alarm automatically.

- On the sand bin, there is vibrator, so it can guarantee normal working.

- There is isolation screen on top of cold bin, so can avoid large material input.

- The conveyor belt use circular belt without joint, steady running and long performance life.

- At the input port of feeding belt conveyor, there is one simple screen can avoid big material input which can enhance hot efficiency and make sure the drying drum, hot aggregate elevator and vibration screen work reliability.

2. Drying System

- The blade geometry of the dryer has been optimized to deliver an exceptionally efficient drying and heating process with reduced energy consumption,improve heating efficiency 30% than conventional design; Because of High heating efficiency, drum surface temperature is relatively low, so the cooling time after operation is considerably shorted.

- Fully insulated and clad aggregate dryer. Drive by electric motors and gear unit through polymer friction drive support rollers.

- Adopt famous brand HONEYWELL temperature intelligent control system.

- Adopt high combustion efficiency Italian brand burner, make sure low exhaust gas emission (like CO2,low No1 & No2, So2).

- Diesel, heavy oil, gas, coal or multi-fuel burners.

3. Vibrating screen

- Improved vibration and amplitude to optimize impact on the available screen.

- Wear-resistant charging system with uniform distribution of the particle mix.

- Wide open doors for easy access and screen meshes are simple to replace, so the down time is reduced.

- The best combination of vibrating direction & screen box dip angle, ensure ratio and screening efficiency.

4. Weighing system

- Adopt famous brand METTLER TELEDO weighing sensor, make sure accurate weighing, in order to make sure the asphalt mixture quality.

5. Mixing system

- Mixer are designed by 3D mixing design, with long arms, shortened shaft diameter and a bi-directional mixing blades array.

- The discharging process has been completely redesigned, the discharge time is minimal.

- The distance between blades and bottom of the mixer is also restrained to the optimal minimum.

- Bitumen is sprayed from multi-points evenly over aggregate by one pressurized bitumen pump to achieve full coverage and high mixing efficiency.

6. Dust Collecting System

- Gravity primary dust collector collecting and recycling bigger fine, saving consumption.

- Bag house secondary dust filter control emission be lower than 20mg/Nm3, eco-friendly.

- Adopt USA Dopont NOMEX filter bags, high temperature resistance and long service life, and the filter bags ban be replaced easily and quickly with no need for special tools.

- Intelligent temperature and control system, when the dust air temperature is higher than set data, cold air valve will be opened automatically for cooling, avoid the filter bags are damaged by high temperature.

- Adopt high voltage pulse cleaning technology, contributing to a lower bag wearing, longer lifespan and better dust removal performance.

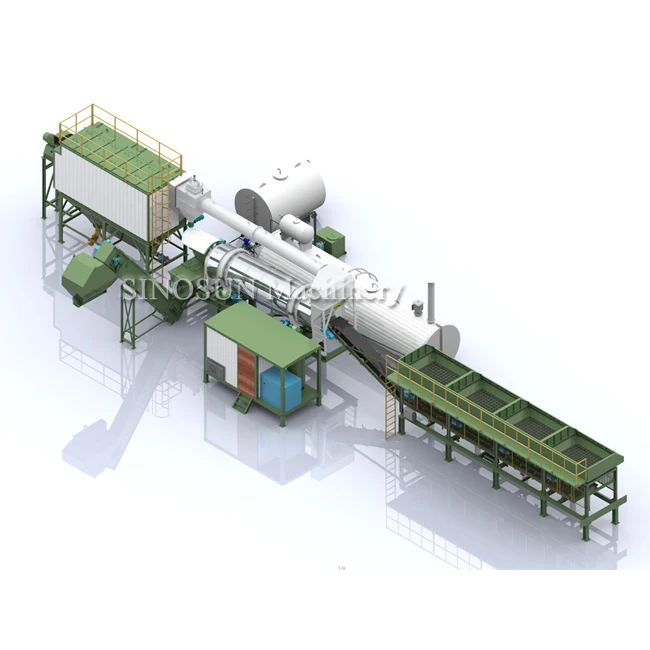

Pictures

click here to send inquiry,engineer will disscus about the asphalt plant details

Zhengzhou sinoroader Machinery Co., Ltd is a professional manufacturer of road andbridge construction machinery. Handa has 12 advanced production lines covering almost all kinds of machinery and equipment used for construction engineering, such as asphalt mixing plant, concrete batching plant and asphalt distributor. Featured products have been exported to Vietnam, Kazakhstan, Pakistan, Russia, Ukraine, Brazil etc.

FAQ

Q1. Are you a manufacturer?

Yes, we have been in special vehicle manufacturing and marketiing for over 20 years.

Q2. What markets do you export to?

Europe, North & South America, South-East Asia,Africa, Oceanica, Middle East countries etc.

Q3. Is it available to print our own brand ?

Totally acceptable as you wish.We can produce according to your requirements,the size, color, materials, logo etc.

Q4. How can I get the price of your product?

You can connect with us through any of the following contact information. Our personalized service person will respond you within 24 hours.

Q5. What is your after-sale service?

12 month warranty.

Provision with relevant technical support.

Available spare parts after ordering.

We can ship construction machinery by various transportation tools.

(1) For 90% of our shipment, we will go by sea, to all main continents such as Middle East, Africa, Oceania and Europe, South America,etc. Either by container or RoRo/Bulk shipment.

(2) For neighborhood countries, such as Russia, Mongolia, Kazakhstan, Uzbekistan

etc.,we can ship construction machinery by road or railway.

Sarah Guo

HENAN SINOROADER HEAVY INDUSTRY CORPORATION

Mob/Whatsapp/Wechat:+86 18137858347

Website:www.sinoroader.com

Похожие товары

Нефтяной Природный асфальтовый Битум для производителя и экспортера дорожного строительства

Непрерывный асфальтовый завод станок смесительный

Хорошая продажа асфальт барабанная смесь заводское оборудование цена

Горячая Продажа 80 т/ч асфальт барабанная смесь завод производитель

Высокая эффективность мобильный асфальтоукладчик для продажи

60t асфальтоукладчик непрерывного смешивания

Передвижные асфальтовые заводы | Портативный асфальтовый завод барабанной смеси для строительства на месте

Новые поступления

Новинки товаров от производителей по оптовым ценам