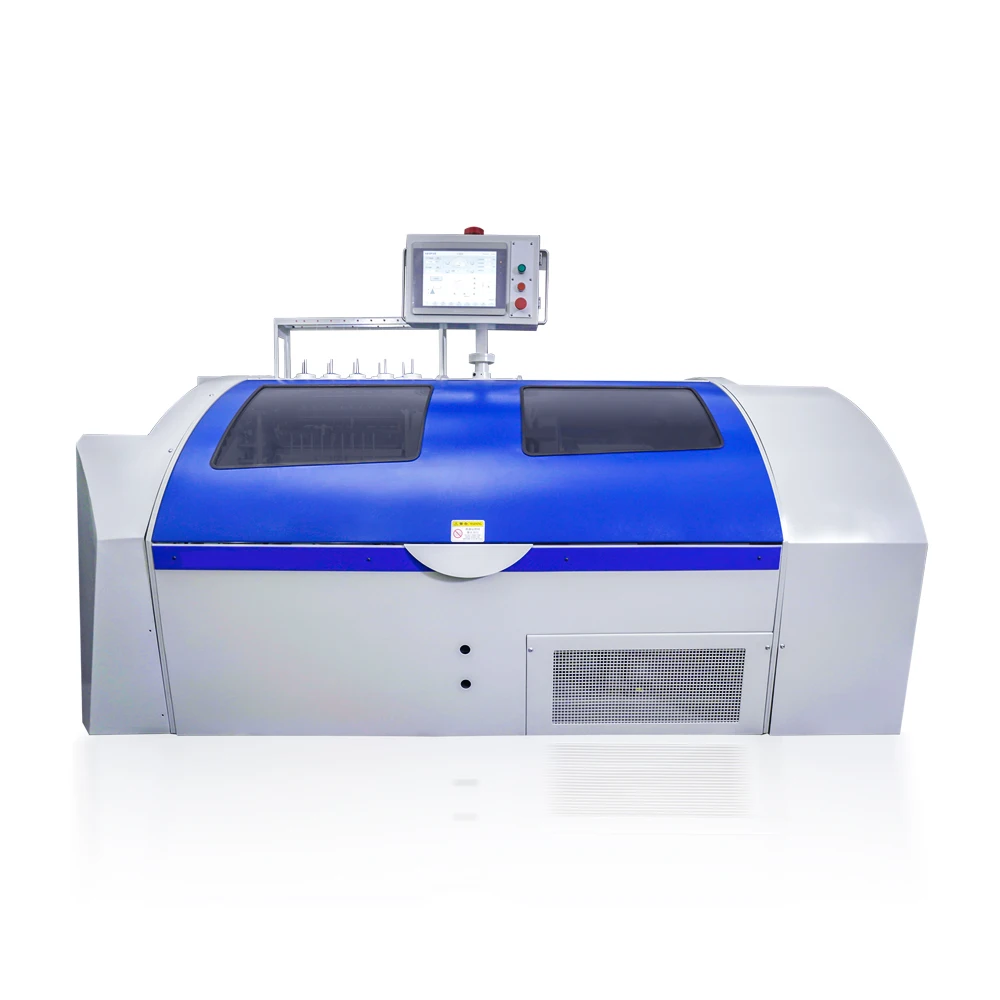

Сделано в Китае Автоматическая Конвейерная сушилка для трафаретной печати длинный размер Трафаретной Печати отверждения машина

- Категория: >>>

- Поставщик: Dongguan Matal Intelligent Equipment Co. Ltd.Dongguan Ltd.

Сохранить в закладки 1601321008045:

Описание и отзывы

Характеристики

Products Description

Details Images

Product Paramenters

Item | Value |

Machine Size | 5000*685*750mm |

Oven Size | 4000*600*300mm |

Available Height | 150~300mm |

Net Weight | 500kg |

Power Supply | 380V 20KW |

Temperature | 0~180°C |

Pallet Height | 1.2mm |

Remarks: The total width of the machine is 68.5 centimeters.

Power part: the use of domestic core-resistant motor 200 watts, with electronic speed controller, speed 1 than 100.

Wire body part: using aluminum 1.2mm thick 40 by 80 to do both sides of the track. The machine foot adopts 40 by 40 aluminum 1.2mm link angle code, with foot back fixed.

Line part: high temperature resistant teflon belt, plus anti-running guide strip, 600mm wide, under the pallet 1.2mm pallet lining. The head and tail roller is made of galvanized plate 76 diameter roller grooved.

Oven configuration: tunnel furnace 2 m * 600mm * 300mm (L * W * H) furnace inlet and outlet height Material: shell made of 1.2 cold plate bending and welding, the inner liner is made of 1.0 galvanized sheet.

Motor: every 2 meters using 1 370w long shaft air transport motor, equipped with 7.5 inch air transport wheel.

Heating pipe: every 2 meters of the furnace each with stainless steel heating pipe, 600 watts a * 12 * multiplied by 2 furnaces a total of 24 total power 15 kilowatts.

Heat insulation: 100K rock wool insulation 40mm thick.

Electric control box: every 2 meters configuration thermostat, Delisi three-phase air switch, Delisi contactor, indicator, rotary switch.

High-temperature line: using 4 square high temperature.

Temperature: 0-180 degrees adjustable.

Marketing Campaign

COMPANY PROFILE

professional technology,professional service

Dongguan Meitu Intelligent Equipment Co., Ltd. is an intelligent equipment manufacturing enterprise specializing in intelligent R&D, design and manufacture of screen printing equipment, focusing on providing high-end energy-saving and

environmentally-friendly full range of screen printing equipment, screen printing equipment and services.

Workshop display

Meitu intelligent equipment is positioned as “one-stop integrated service provider for screen printing enterprises”, with technological innovation and intelligent R&D design as the core of the enterprise, and always adhere to the innovative concept of one step ahead of technology. Leading and promoting the technological advancement and technological

innovation of silk screen printing equipment, the company's intelligent silk screen printing equipment, electromechanical equipment, automation equipment, etc., played a huge role in the printing industry of nearly 30 provinces, municipalities and autonomous regions in China, for Chinese cigarettes. The wine packaging, clothing and hat printing, ceramic flower paper, electric bicycle and bicycle decals, electronic and electrical circuit boards, mobile phone glass, equipment manufacturing and other industries have made important contributions.

innovation of silk screen printing equipment, the company's intelligent silk screen printing equipment, electromechanical equipment, automation equipment, etc., played a huge role in the printing industry of nearly 30 provinces, municipalities and autonomous regions in China, for Chinese cigarettes. The wine packaging, clothing and hat printing, ceramic flower paper, electric bicycle and bicycle decals, electronic and electrical circuit boards, mobile phone glass, equipment manufacturing and other industries have made important contributions.

Printing, hot stamping effect

Customer Samples 1-1 Customer Samples 1-2

Customer Samples 1-3

company certificate

Customer Recognition & Feedback

Похожие товары

ИК-сушилка для горячей сушки сушильная машина конвейерная ленточная сушилка по самой низкой цене

VML-1 детектор утечки R410a R32 хладагент снег холодильник кондиционер галогенный оригинальный зонд

9 535,65-10 807,07 ₽

HX180 автоматическая швейная машина с сердечником моторного насоса ПЛК подшипник для переплета книг производство ресторанов и типографских магазинов

13 133 976,80-13 254 472,00 ₽

Ручное производство небольшой записной книжки швейная машина нитки бумага электрическая нитка переплетная для книг продажа

240 990,40-481 980,80 ₽

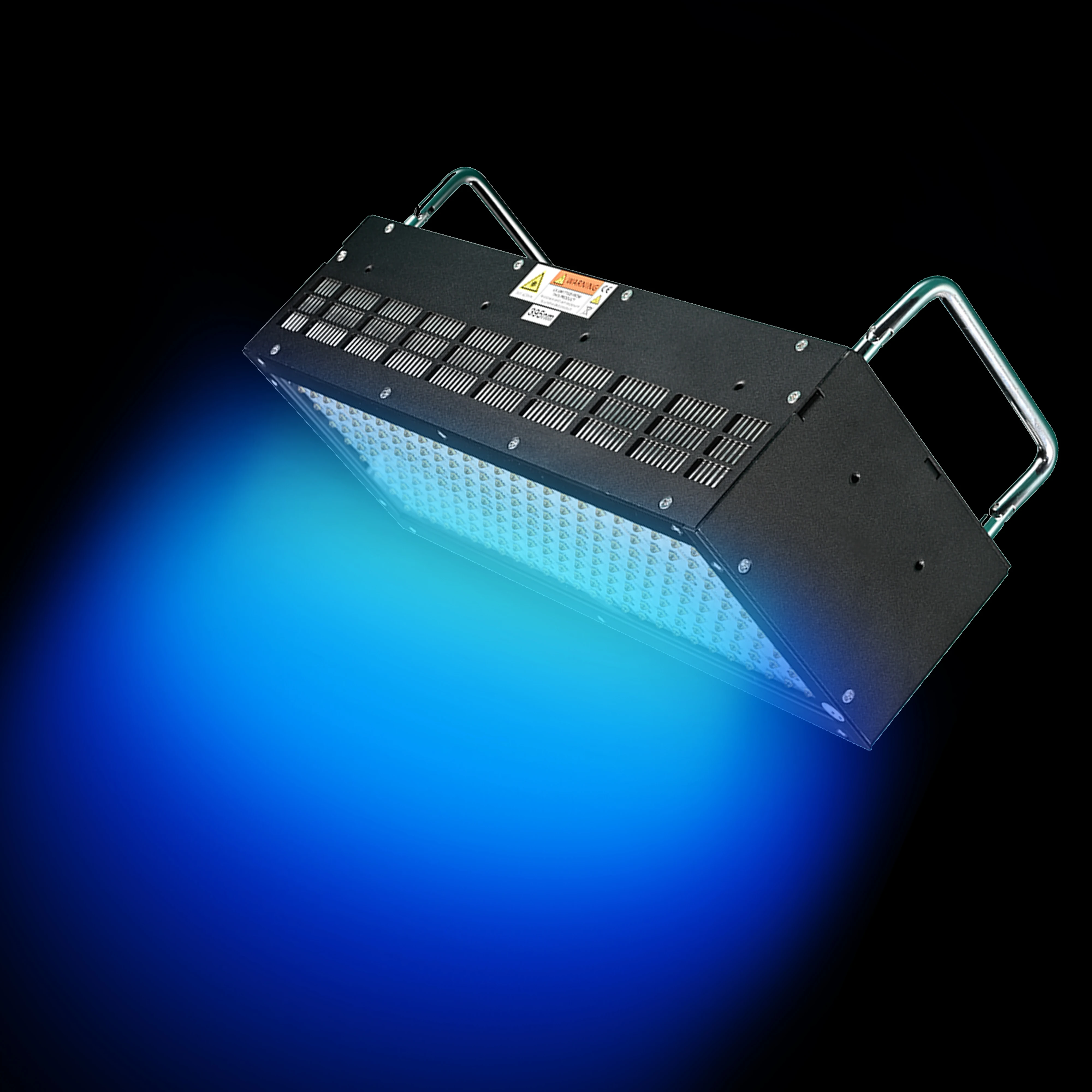

900 Вт светодиодная УФ-лампа для УФ-лака из клеевой смолы быстрое отверждение с 5-дюймовым контроллером

Машина для изготовления обложек книг

867 565,44-1 022 040,29 ₽

A3 рулон в УФ-пленка DTF ламинирующая машина

11 929,03-14 459,43 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $