Оборудование для производства электроники

- Категория: >>>

- Поставщик: Shenzhen Wisdomshow Technology Co. Ltd.Shenzhen Ltd.

Сохранить в закладки 1601332610422:

Описание и отзывы

Характеристики

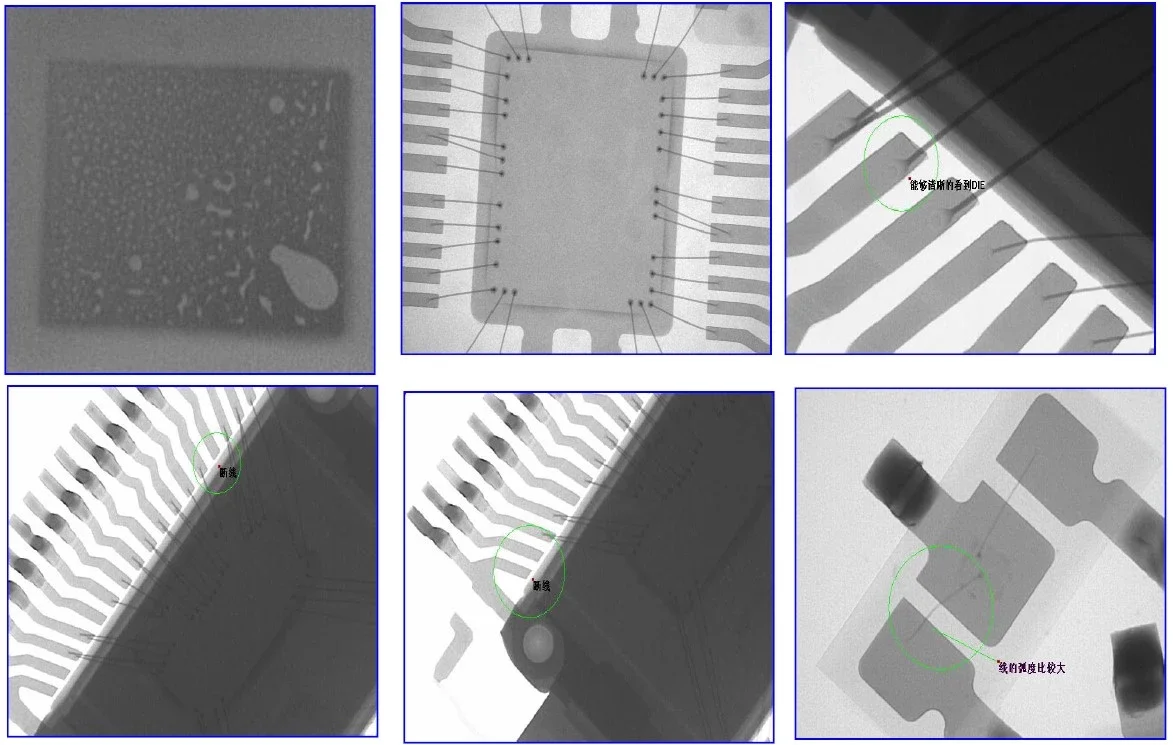

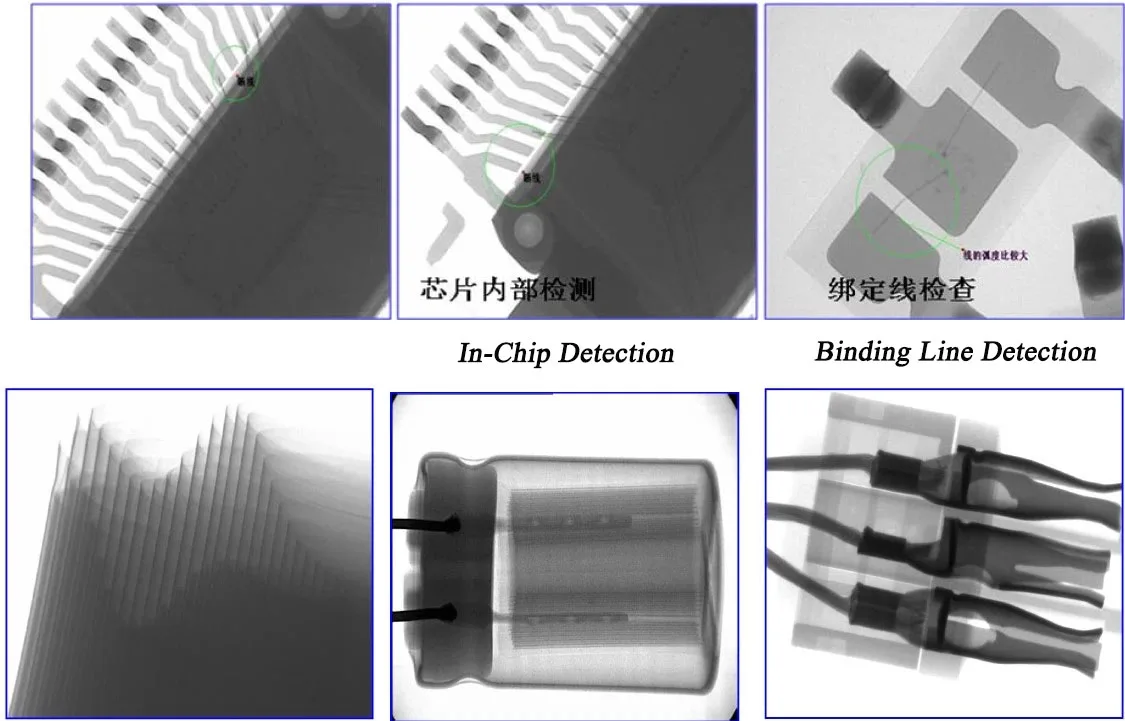

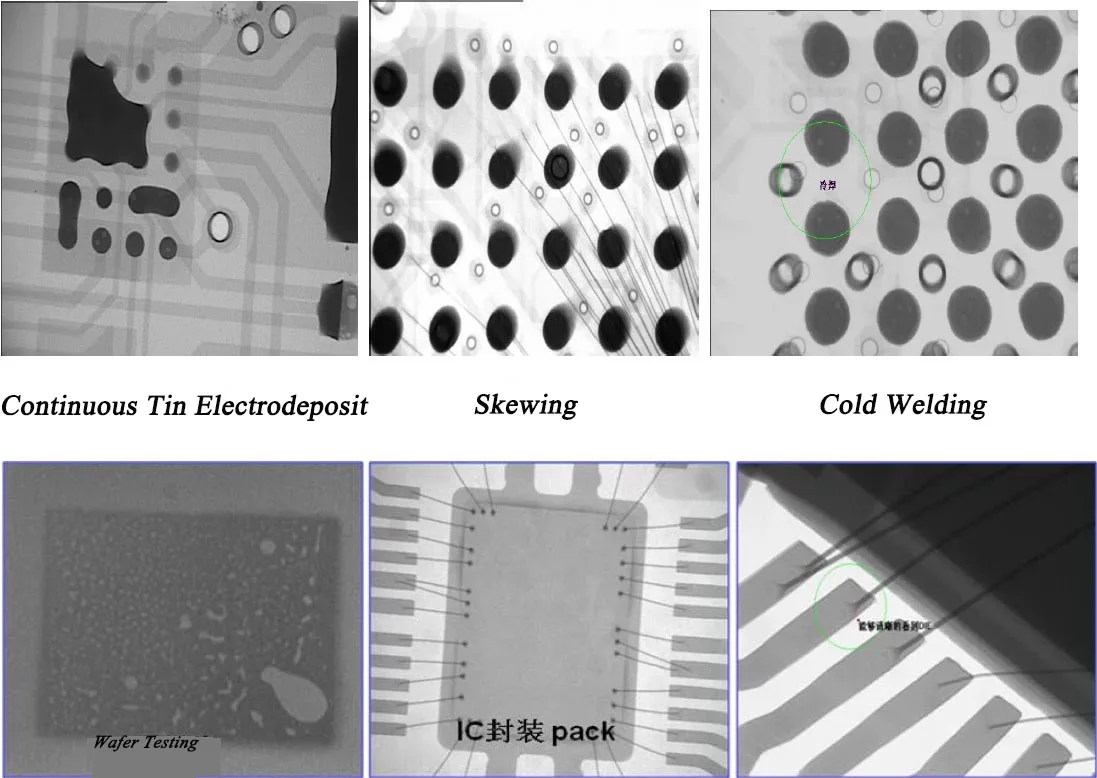

Application Domain

Product Description

Power supply | AC 110V/220V 50/60Hz |

Total power | Max 1600W |

Heater power | Tube current 10-89uA |

Locating way | V shape slot,PCB support jigs can adjust,laser light do fast centering and position |

Temperature controlling | (high precision K-sensor)(Closed Loop),independent temp.controller,the precision can reach ±1℃ |

Electrical material | Driving motor+ smart temp.controller+color touch screen |

Computer | DELL Windows10 |

Tin spot monitoring | Optional external camera to monitor solder ball melting process during welding |

Camera in and out | Auto out & in |

Overall dimension | L600×W640×H850mm |

Operation mode | 5 working modes. Auto/ manual mode switch freely |

Weight | 1500KG |

Detailed Images

1.Automatically pick up and replace chips;

2.Built-in pressure testing device,can detect pressure of 0.8g.While the testing device detect the pressure,the machine head will stop falling automatically to protect PCB from being crushed;

3.Different sizes of vacuum sucker work for different sizes of chip.

2.Built-in pressure testing device,can detect pressure of 0.8g.While the testing device detect the pressure,the machine head will stop falling automatically to protect PCB from being crushed;

3.Different sizes of vacuum sucker work for different sizes of chip.

1.Prevent IC chip from being dropped and burnt

2.Infrared heating is more easily absorbed by PCB

3.More effectively prevent PCB from defomation,make heating more evenly

2.Infrared heating is more easily absorbed by PCB

3.More effectively prevent PCB from defomation,make heating more evenly

Sensitive MCGS touch screen

1.7〃HD Touch Screen

2. Resolution:800*480

3. Multi storage 5000+ temperature profiles for different chip;

4.Display set and practical temperature;

5.English,Spanish,French and other languages are available.

1. 8 segments of temperature up/down and 8 segments of constant temperature control,mass storage of temperatures,analyze curve.

2. Set different temperature for different chip.Same and similar PCB use same profile. Time-saving.

2. Set different temperature for different chip.Same and similar PCB use same profile. Time-saving.

Precise CCD optical alignment system |

1. 15〃Color HD LCD display |

2. 8 million pixels |

3. Mounting accurancy within 0.01mm |

4. Shows the image of every soldering joint,increase the repair success rate. |

5. Yellow point is the soldering point on PCB,blue point is the soldering point on BGA chip. |

♦ Second heating zone height adjust

Distance between PCB and nozzles can be adjusted withi this rotary handel,suitable distance is 2-3mm

♦ Heating zone adjust switch

Can switch off the heating plate on both sides if the motherboard is small

♦ Laser position

Location the chip fast

♦HD camera contrl

Controlled by motor to in/out

♦ Micrometer

1.Slightly adjust angel of chip for precise alignment

2.Mounting accuracy within 0.01mm

3.Effectively increase success rate of repairing

2.Mounting accuracy within 0.01mm

3.Effectively increase success rate of repairing

♦ K-sensor

Test the temperature to get the accurate heating profile

Packing & Delivery

1,Standard export wooden package for bga rework station:70*81*90cm,105KG;

2,Delivery in 2 workdays after payment confirm;

3,Shipping by TNT, UPS ,DHL,FEDEX, EMS or by air ;

4,Loading port: Shenzhen or Hongkong.

Why Choose Us

● We are manufacturer = own factory+ machine design+sheet metal produced by ourselves+spray the powder+

strong assemble the machine team + packaging+free training

● Rich experience in BGA rework station field

● Develop new products to meet different requirements based on customer feedback

● Provide OEM services

● 100% NEW from WDS factory

● Have excellent teams and focus on product development & design, quality control & inspection

● Good reputation both at home and abroad

strong assemble the machine team + packaging+free training

● Rich experience in BGA rework station field

● Develop new products to meet different requirements based on customer feedback

● Provide OEM services

● 100% NEW from WDS factory

● Have excellent teams and focus on product development & design, quality control & inspection

● Good reputation both at home and abroad

Business Partners

Похожие товары

Лидер продаж DH-A2E станция для передела 3 в 1 bga

4 500,00-5 999,00 $

150 Вт 300 500 волоконно-лазерное сварочное оборудование Высокоскоростной гальванометр лазерный сварочный аппарат

2 800,00-3 000,00 $

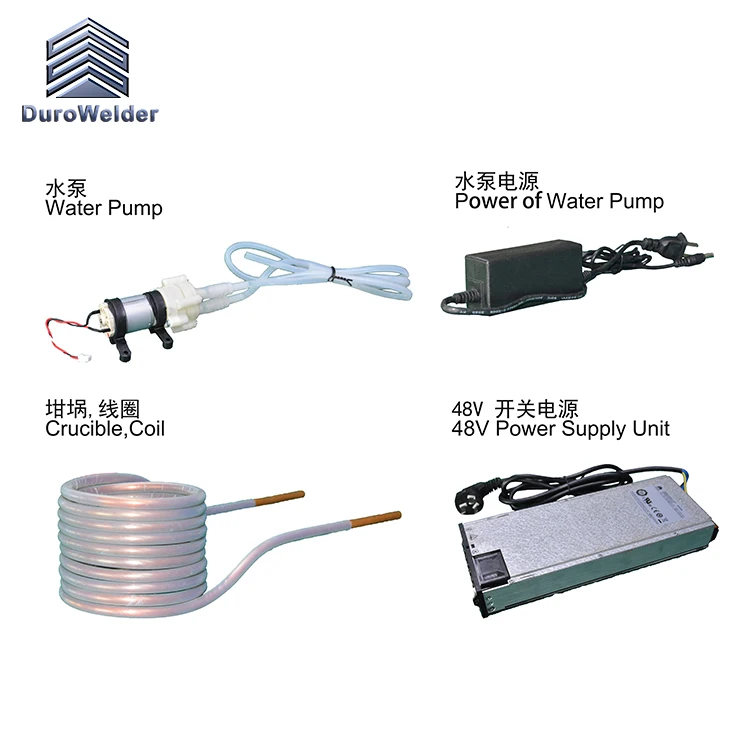

Индукционный нагреватель средней частоты индукционный

850,00-900,00 $

SIH-3KW маленький индукционный нагреватель

110V Индукционный Нагреватель Машина для автомобильной краски меньше вмятин ремонт инструменты удаления инструмент

Автоматический нагреватель температуры нагрева металла индукционный Пайка для эффективной пайки.

902,00-950,00 $

1-фазный 50 Гц машина индукционного нагрева 5KW четырехтактный двигатель с воздушные охлаждением для PWHT

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $