2024 Китай профессиональное оборудование для производства порошка гипса

- Категория: >>>

- Поставщик: Henan Dafu Mechanical Import And Export Co. Ltd.Henan Ltd.

Сохранить в закладки 1601332691700:

Описание и отзывы

Характеристики

2024 China Professional Gypsum Powder production equipment

We have designed different proposals separately for the annual capacity below 50 000 tons and above 50 000 tons . For the customer who need annual capacity below 50 000 tons ,we design one step technique which is of low cost and simple workflow .while for the above 50 000 tons we design 2 steps technique which is designed very reasonable and has good equipments. Both technique can produce qualified and stable products . To cater to the heat resource in the power plant which uses vapor ,we have developed the calcinations plan with vapor as the heat resource.  And it is already successfully used in HUAYANG power plant project.

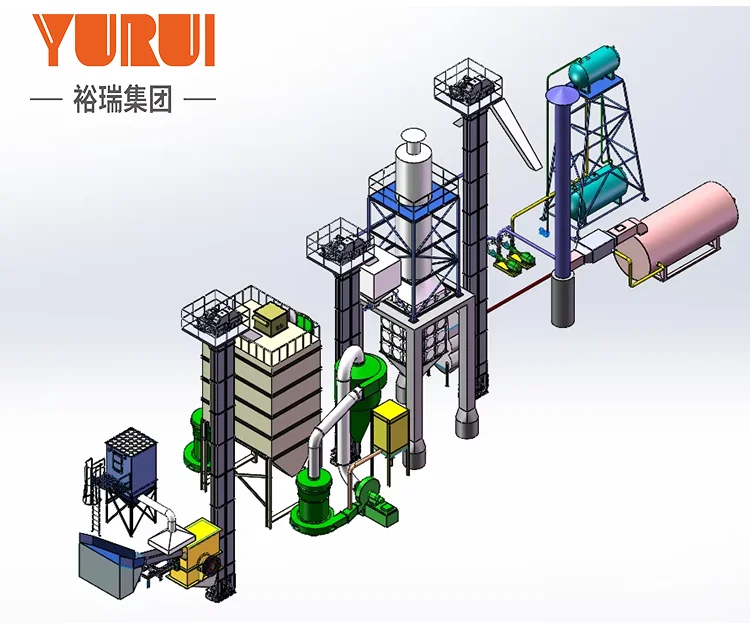

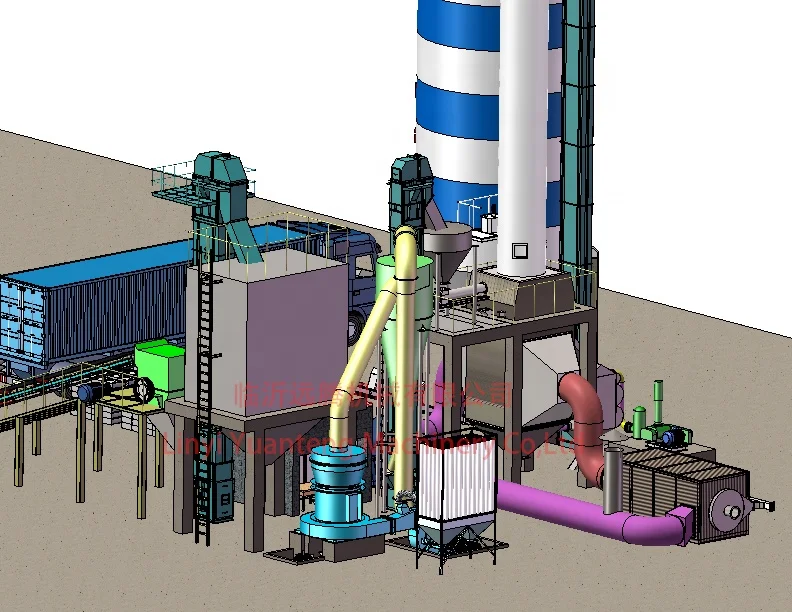

Gypsum powder production line flow chart:

The gypsum powder production line of which the material is natural gypsum, are equipped with many advanced technological equipment in domestic and foreign such as material averaging device, double-grade crushing system, plate type conveyor, vertical mill, Ramon mill, gypsum boiling kiln, cooling machine and waste heat recycling system, etc. The boiling kiln is widely used in our nation with the advantages of small, simple, great output, small occupied area, easy control, perfect gypsum micro-structure, stable physical properties and low running cost. It has been sold to Thailand, Uzbekistan, Columbia and Mexico along with our production line.

Fuel variety: Coal, fuel oil, natural gas, or liquefied petroleum gas

Gypsum powder mill

Raymond Mill is applicable to the grinding and processing of more than 280 kinds of non-flammable and non-explosive materials with hardness less than 7 and humidity less than 6% in mining, construction, chemical industry and metallurgy, such as barite, calcite, feldspar, talcum, marble, limestone, clay, glass. The fineness of the finished product can be adjusted from 100 mesh to 325 mesh according to requirements.

New-type gypsum frying boiler- ebullience calciner

First grind and second bake. The largest advantage of this technique, compared with that of “first bake and second grind”, is energy consumption reduction. Large plaster stone shall be ground into powders with diameter less than 0.2mm, which increases the specific surface when calcining, enlarges the contact area with heat medium, improves calcinations heat exchange efficiency and lowers energy consumption greatly. This equipment has small bulk, large production capacity, and simple structure and is hard to destroy.

Electrostatic dust collector

itworks is to use of high-voltage electric field to ionize the flue gas, charged dust in the air flow in the electric field and the flow separation. , Called the discharge electrode, a negative electrode is made by the different cross-sectional shape of the metal wires. The positive electrode is made of a different geometric shape of the metal plate, called the collecting electrode. Electrostatic precipitator performance by the three factors of the dust characteristics, device structure and the flue gas flow rate. The specific resistance of dust is to evaluate the conductivity indicators, and its removal efficiency has a direct impact.

Main characters of heat-conducting oil boiler :

1. High automaticity, prompt start and stop, high reliability.

2. High thermal efficiency, completely burning, stable output, better adaptability to variable load.

3. Compact structure, small area requirement.

4. Less auxiliaries, easy installation.

5. Less pollutant emission, can reach higher Environmental protection index.

Electrical control system

The current advanced DCS(distributed control system) is selected for the electrical control system, and the PLC is chose from Japan’s Mitsubishi company, which could centralized control equipment that scattered in different parts. It becomes the first choice for modern building industry due to low labor, cost and high efficiency.

Electromagnetic feeder

Elevator

Belt conveyer

Advantages of plaster of paris powder production line:

1. has built many lines for oversea company, such as Columbia, Uzbekistan (2 buyers), Mexico, Italy, USA, etc.

2. use hot oil or natural gas technology

3. Turn-key project, including design, istallation, commissioning and training until finish inspection and acceptance.

For over twenty years, our products and services have been enjoying a good reputation in this import and export market.

We provide the best pre-sale, sale and after-sale service. We have a professional working team that can allocate the complete line for you, to ensure that you buy the best quality and fittest machine in least money. After sale, we provide one-year warranty to make sure that your machine runs functionally and consistently. We also provide lifelong services and spare parts for the machine.

Why choose us!

- Manufacturer&Reasonable price√

- We have our own factory with efficient mature production system

- experienced &professional √

- we have more than 20years history! Our team consists of qualified Engineers, Sourcing professionals, Operations professionals, and a select group of premium vendors here

- excellent quality√

- we ensure every production should be safe and have good operation.

- Best after-service√

- Our experienced engineers are ready to provide you with pre-sales post-sales technical support

Packaging Details: |

standard export packing, 20ft, 40ft container, equipment fittings,electric motor and power cabinet |

Delivery Detail:

|

30 working days after receiving the payment |

Henan Dafu Mechanical Import and Export Co. Ltd. , located in Zhengzhou,Henan province, is specialized in manufacturing with more than 20 years’ development and running experience. With high career-honoring spirit and good servicing attitude by all staffs,our company won praise and recognition in the market. We supply quality products and services to customers at home and abroad by good reputation and excellent technology.

If you want to learn more about our production and company ,please contact with me !

//dafumachinery.en.alibaba.com/

Похожие товары

Машина для производства кормовых гранул 400 типа бытовая мелкая аквакультура сухая и влажная машина двойного назначения

2024 весь набор гипсовый порошок сушильная машина/Жидкий слой печи для продажи

2024 Горячая продажа 200 тонн в день гипсовый порошок вертикальная линия котла для прокаливания/печь с жидким слоем

Высококачественный промышленный вертикальный газовый угольный масляный гипсовый порошковый кальцинатор нового типа

Карбонат кальция/гипс/Известняк/кварц/графитовый порошок производственной линии

Линия по производству гипсового порошка 170 тысяч TPY

Высокоэффективные надежные гипсовые машины SBM подходящие для известняковых заводов 30 тонн и 100 сетчатая гипсовая машина

Новые поступления

Новинки товаров от производителей по оптовым ценам