Сварочное оборудование для сварочных труб

- Категория: >>>

- Поставщик: Shanghai Mwelding Intelligent Technology Co. Ltd.Shanghai Ltd.

Сохранить в закладки 1601335653627:

Описание и отзывы

Характеристики

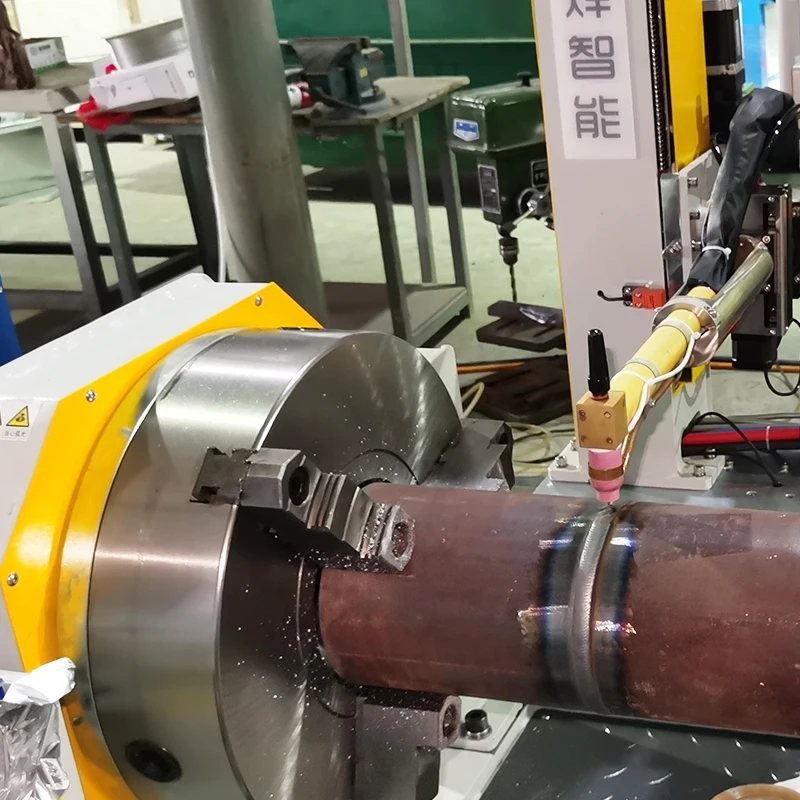

Angle Swing Circumferential Seam Welding Equipment for Tube Welders

Suitable pipe diameter:Φ50mm-Φ500mm

PRODUCT INTRODUCTION

1. The equipment adopts compact and intensive design, small shape, flexible operation, no occupation of land, practical Tig welding;

2. It is suitable for ring seam welding of carbon steel, stainless steel, titanium alloy, aluminum alloy, nickel base alloy and so on;

| Can be used for pipe, pipe tee, pipe elbow, pipe flange and other pipe fittings docking and plug; |

| The full angle positioner, combined with the sliding and adjusting mechanism of welding torch, can accurately realize the requirement of multi-angle displacement of welding work piece; |  |

| Equipment configuration and process are optional and adjustable according to demand, and have stronger economy, adaptability and compatibility; |

| Welding control function is fine and comprehensive, supporting speed control. Current control, wire feeding control, rotation control, gas protection time control and arc length automatic control, etc; |  |

| Perfect welding feed system, wire feeding system, oil circuit system. The cooling system ensures the stable operation of the equipment for a long time. |

| Diameter of weldable work piece | Φ50mm~500mm |

| Moving stroke of welding gun | 0-1800(Customizable) |

| Spindle rotation speed | 0.1-2rpm |

| Vertical electric carriage travel | 0-300mm |

| Mobile trolley | 0-1800(Customizable) |

| Electric arc long stroke | ±60mm |

| Swing angle | ±30° |

| Weight | 250KG |

| Model | MWHF-ZM | MWHF-ZL |

| Diameter of weldable work piece | Φ30~400mm | Φ50~500mm |

| Moving stroke of welding gun | 0-1000mm(Customizable) | 0-1800mm(Customizable) |

| Spindle rotation speed | 0.1-3rpm | 0.1-2rpm |

| Vertical electric carriage travel | 0-300mm | 0-300mm |

| Mobile trolley | 0-1000mm(Customizable) | 0-1800mm(Customizable) |

| Electric arc long stroke | ±60mm | ±60mm |

| Swing angle | ±30° | ±30° |

| Weight | 250KG | 250KG |

Shanghai MWelding Intelligent Technology Co., Ltd

Shanghai MWelding Intelligent Technology Co., Ltd. was established in 2012, focusing on the production of fully automated pipe welding equipment, automated specialized welding equipment, and integrated welding control power supply as a technology-based innovative technology enterprise. The company adheres to the business philosophy of "customer-oriented, customized, and integrated services without outsourcing", focusing on innovative research and development, processing and production, marketing, and after-sales service. We continuously innovate and optimize our research and development, providing customers with comprehensive technical solutions and high value-added services.

Won honors such as high-tech enterprise,

ISO9001 certification, ISO45001 certification, CE certification,

multiple utility model invention patents, and national AAA level integrity enterprise

1.Where is your factory located?

Our factory is located at Building 7, No.669 Zhongde Road, Songjiang District, Shanghai. Welcome to visit us anytime!

2.Does your company have any qualification certificates?

Yes, our company is a national high-tech, ISO and CE certified enterprise, with multiple patent certificates.

3.What is orbital welding and what can orbital welding machines be used for?

Orbital welding is a technique that connect two objects under a high level of heat. The argon arc automatically rotates 360 degrees around the tubes to create high-quality welds with the control of digital system.

Automatic orbital welding machines can be applied in various industries, such as heat exchanger, pharmaceutical, food, cooling, water treatment, pressure vessel, boiler and many other fields.

4.What are the advantages of automatic welding machines?

After the application of automatic welding machines, the appearance and internal quality of welded parts have been greatly improved. The stability of quality has been ensured while reducing labor intensity, improving the working environment, reducing manual welding skill requirements and production costs, and increasing production efficiency.

5.What other products does your company offer?

Our company offers pipe to pipe welding machine, all position tube sheet welding machine, u-shaped tube welding machine for heat exchanger, automatic circumferential seam welding machine, hot wire overlaying welding machine, argon arc welding machine, orbital welding machine for stainless steel pipe, and so on.

6.Does the company provide customized services for welding machines?

Yes, our company has been focusing on the production, research and development, and design of automatic welding equipment for over ten years. We have professional engineers and technicians to customize according to your specific requirements and needs.

7.How is your company's after-sales service?

We have established an instant response mechanism, where technicians can answer your questions about the operation process anytime and anywhere. We promise to response the email consultation content within 6 hours

For customers, we will arrange professional personnel for on-site operation training, and each equipment will also be equipped with standard operation training manuals for reference

All equipment is uniformly guaranteed for at least one year, and regular maintenance services are provided to reduce equipment consumption, save equipment maintenance costs and operating costs

8.How should I choose the product I need?

Contact us directly through our website, email, WhatsApp, or phone. Please provide your requirements and needs, such as pipeline type, welding materials, delivery time, quantity, customization requirements, etc. Once we receive the information, our sales will help you select the welding machine that best meets your requirements, provide you with a detailed quotation, and answer any questions you may have.

Похожие товары

Сварочный аппарат aotai/сварочный для алюминиевой дуговой сварки под флюсом MZ-630/maquina de soldar

MZ-1250 высокочастотный инвертор Многофункциональный погружной дуговой сварки

Сварочный аппарат для дуговой сварки 140 А

MZS-1000 Двойной источник питания/двойной провод погружной дуговой сварочный аппарат

MZ-630 машина для дуговой сварки под флюсом/сварочный аппарат maquina de soldar/сварочный алюминия

3-фазный погружной дуговой сварочный аппарат сварочное оборудование MZ 1250 с трактором

Китайский завод Cnc автоматический козловой Тип H лучевой дуговой сварочный аппарат

Новые поступления

Новинки товаров от производителей по оптовым ценам