Небольшой 5 осевой фрезерный станок с ЧПУ VMC640 небольшой обрабатывающий центр одним шпинделем конкурентоспособная цена система управления Siemens

- Категория: >>>

- Поставщик: Xiamen Daxing Industry Co. Ltd.Xiamen Ltd.

Сохранить в закладки 1601336148745:

Описание и отзывы

Характеристики

Company Profile

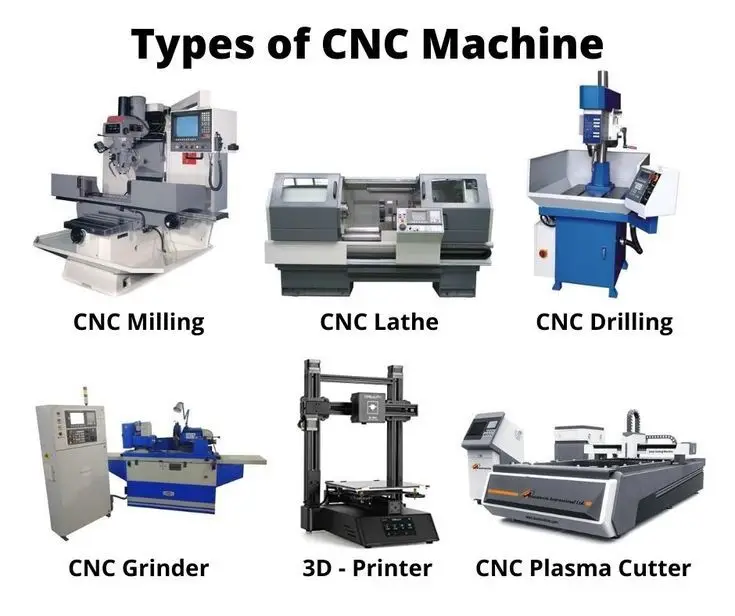

In milling – unlike metal turning – the workpiece remains stationary and the mobile cutting edges of the CNC machine move to remove the excess material. This type of machining ensures exceptional accuracy and repeatability, even when making very complex parts and components

Modern industry requires the use of increasingly complex parts that can only be obtained with the help of appropriate technologies. CNC milling is a good example of this. By incorporating computer-controlled numerical devices into the processing process, a high level of precision is achieved, resulting in high quality components and complete repeatability.

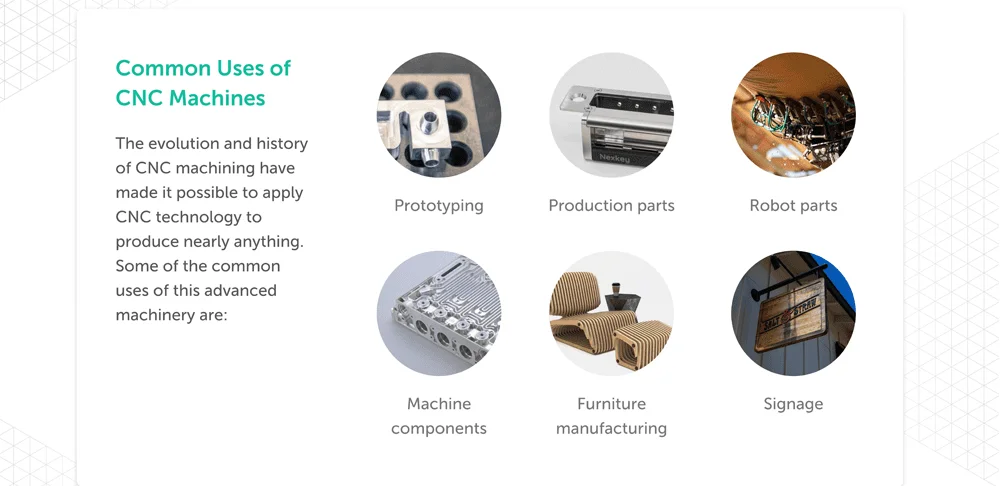

Due to the exceptional accuracy achieved by CNC machines, they are used primarily to form metal shapes. The most common is steel. It has a high degree of hardness, however that does not interfere with our machines capacity for precise machining. Stainless steel milling also includes related material groups such as austenitic or heat resistant. This range also includes structural steel, hardened steel, spring steel and many more.

A CNC milling machine can easily handle cast iron blocks (white, gray, black), aluminum and its alloys, tungsten, molybdenum or magnesium. It is also possible to mill copper, nickel super alloys or titanium, as well as various types of composites (especially thermoplastic and thermosetting plastics).

neo | M8Cube | MLCube | MXCube | |

Travel (XYZ) | 520 x 420 x 220 mm (20" x 16.5" x 9") | 1,020 x 830 x 245 mm (40" x 33" x 10") | 1,520 x 1,150 x 245 mm (60" x 45" x 10") | 1,040 x 850 x 270 mm (41" x 33.5" x 11") |

Spindle | 2kwatt liquid chilled spindle up to 40,000 RPM | Up to 60,000 RPM | Up to 60,000 RPM | Standard 4 kwatt, 1k – 40k RPM, e-25 HSK Collet Upgrade 8 kwatt, 100 – 34k RPM, e-32 HSK Collet |

Feed | Up to 28 m/min (1,102 in/min) | Up to 22 m/min (866 in/min) | Up to 22 m/min (866 in/min) | Up to 40 m/min (1,574 in/min) - X, Y Up to 28 m/min (1,102 in/min) - Z |

Tool Changer | 24 stations automatic tool changer | Up to 143 stations automatic tool changer | Up to 143 stations automatic tool changer | 143 tool change capacity |

Working Area | 500 mm x 400 mm (19.5" x 16") | 1,000 x 700 x 200mm (39" x 27.5" x 7.5") | 1,500 x 1,000 x 200mm (59" x 39" x 7.5") | 1,000 x 700 x 200mm (39" x 27.5" x 7.5") |

Rotary axis | Optional 4th axis | Optional 4th axis and 5th axis | Optional 4th axis and 5th axis | Optional 4th axis and 5th axis |

Footprint (W x D x H) | 805 x 1,290 x 1,880 mm (32" x 51" x 74") | 1,740 x 1,740 x 1,950 mm (69" x 69" x 77") | 2,410 x 2,280 x 1,950 mm (95" x 90" x 77") | 3,358 x 1,855 x 2,235 mm (106″ x 73″ x 88″) |

Weight | approx. 700 kg (1,543 lbs.) | approx. 1,300 kg (2,866 lbs.) | approx. 2,500 kg (5,512 lbs.) | approx. 3,800 kg (8, 378 lbs.) |

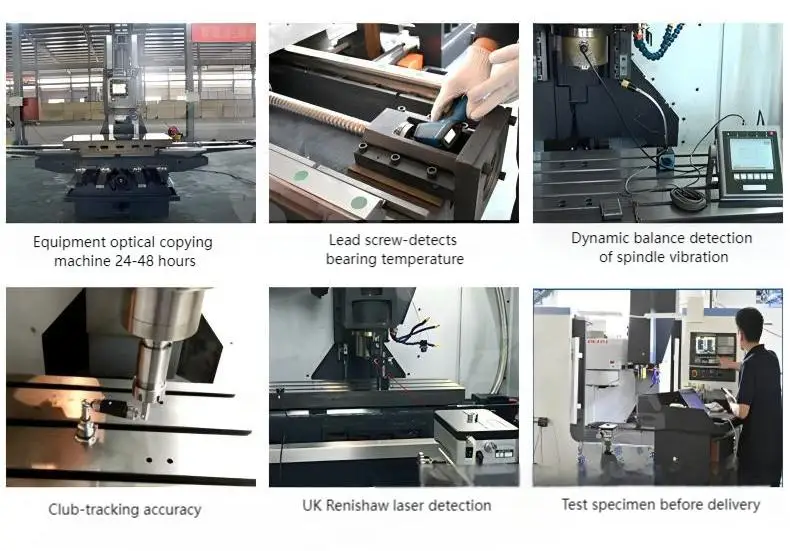

Products Description

Похожие товары

XK7126 тэнчёоу зубные 5-осевой фрезерный станок с ЧПУ цена

Высокоскоростная линия сверлильного станка с ЧПУ для стальных угловых стержней

177 912,75-237 217,00 ₽

XH1050 3 оси вертикальный Китай фрезерный станок с ЧПУ Тайвань линейный направляющей

Высокая точность fanuc фрезерный станок с ЧПУ XK7140 3 оси для продажи

3-осевая линейная направляющая

2 690 151,30-3 274 966,80 ₽

Низкая цена высокое качество 3-осевой мини-фрезерный станок с ЧПУ TVK720 фрезерный Китай

1 111 149,45-1 403 557,20 ₽

Небольшой фрезерный станок с ЧПУ 4-осевой Xh7126

1 495 958,05-1 655 027,87 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $