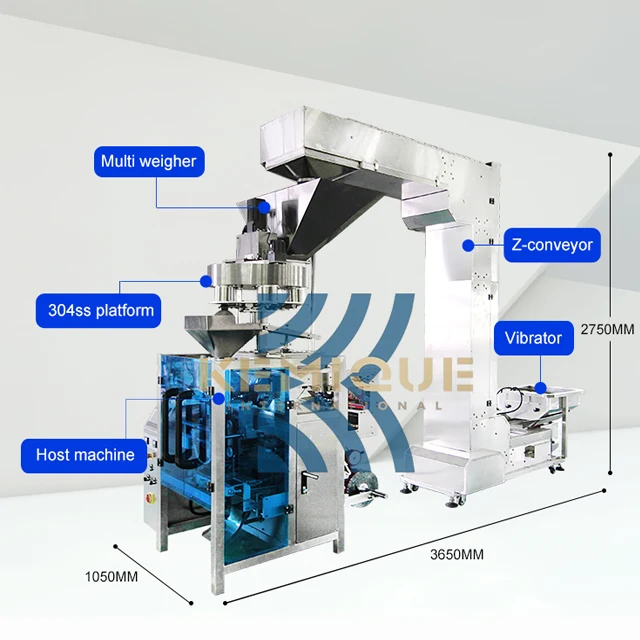

Упаковочная машина для серных гранул 10 кг 25 50 многофункциональная упаковочная количественного взвешивания

- Категория: >>>

- Поставщик: Shandong Guanjia Intelligent Equipment Co. Ltd.Shandong Ltd.

Сохранить в закладки 1601338213949:

Описание и отзывы

Характеристики

DCS-Z-D-50 Technical Parameters And Characteristics | ||||||||

Body Material | Carbon Steel. Plate thickness ≥ 2.5mm | |||||||

Hopper Material | Stainless Steel 304 Contact parts or Customized | |||||||

Gross Weight | 700KG | |||||||

Packing Capacity | 300-400Bags / H | |||||||

Quantify Precision | 5-50kg or Customized | |||||||

L×B×H(mm) | 2400*1000*2600 | |||||||

CBM(m³) | 4m³ (For reference ) | |||||||

Power | 1.3kw | |||||||

Power Supply | AC 220V/380V 50 HZ or Customized | |||||||

Air Source | 0.5~0.7MPa 0.36m³/min 3KW air compressor(Opitional) | |||||||

Packaging accurary | ± 0.2% F.S | |||||||

Relative temperature | -10~40℃( 14-104℉) | |||||||

Packaging bag | Paper Bag, Woven Bag,Kraft Paper Bag,Nylon Bag, Aluminum Foil Bag, Plastic Bag | |||||||

Sealing method | Sewing:Paper bag, woven bag,Craft Paper,Nylon Bag (Optional)Hot sealing machine: Nylon Bag, Aluminum Foil Bag, Plastic Bag, PE Bag | |||||||

Application Material | The DCS-Z-SD-50 quantitative packaging scale is suitable for large bag packaging of materials and can be widely used in industries such as grain , feed, food and chemical industry. It consists of mechanical devices, electronic weighing devices, and intelligent control systems for instruments. Mechanical devices include feeding mechanisms, bag clamping mechanisms, internal and external supports, etc; The control system includes sensors and intelligent weighing instruments within the weighing system. Food industry: Soybeans, Rice, Corn, Wheat, Peas, Potatoes, Candies. Chemical industry: Potassium chloride particles, Ammonium sulfate, Polyester resin, Resin particles, Magnesium sulfate, Rubber particles,Ammonium hydride, Trisodium phosphate, Urea polyacrylamide, Disodium hydrogen phosphate, Activated carbon particles,Didi wax particles, Glass microspheres, Snow melting agents, Humic acid particles, etc Fertilizer industry: BB fertilizer, Blended fertilizer, Compound fertilizer,Nitrogen fertilizer, Phosphorus fertilizer, Potassium fertilizer, Diamine, urea, Organic compound fertilizer, Corn compound fertilizer, etc Construction industry: River sand, Quartz sand, Gravel, Real stone, etc Pet industry:Dog food, Cat food, Cat litter, etc | |||||||

Functional Features | The DCS-Z-D-50 quantitative packaging Machine adopts automatic control for fast and slow feeding, quantitative feeding, bag clamping, and unloading, except for the working bag. Set control parameters such as fast and slow feeding rates and display overload alarms on the instrument; Weight accumulation and configurable automatic printing output. This device also has the characteristics of fast packaging speed, high packaging accuracy, good stability, and easy operation. 1. Used for packaging ultrafine powder below 325 mesh. 2. Single dragon three-speed feeding, high packaging accuracy and fast speed. 3. The overall mechanical structure is reasonably designed. 4. The control cabinet is sealed and suitable for harsh dust environments. | |||||||

Discharge Port

• The parts in contact with the material are made of stainless steel, which has strong corrosion resistance • Circular and

crocodile shaped discharge ports can be selected based on material properties • Use AirTAC cylinder as power for stable

performance, longer service life.

crocodile shaped discharge ports can be selected based on material properties • Use AirTAC cylinder as power for stable

performance, longer service life.

Sewing Machine

•It can be divided into fully automatic light-sensitive sewing machines and semi-automatic foot operated sewing machines for you

to choose from •Suitable for woven bags, Paper bags,PP/PE bags,kraft paper bags •Double thread sewing, Maximum sewing thickness

8mm •It detects bags’ position by photoeletric sensor and automatically disconnect,Save labors

to choose from •Suitable for woven bags, Paper bags,PP/PE bags,kraft paper bags •Double thread sewing, Maximum sewing thickness

8mm •It detects bags’ position by photoeletric sensor and automatically disconnect,Save labors

Conveyor Belt

1.Carbon steel/stainless steel materials are optional 2.Width and height can be customized and adjusted

DH Intelligent Control Instrument

1.The control instrument adopts a brand new high-definition intelligent touch system, which displays packaging progress, machine operation status, packaging weight, etc

2.Support switching between Chinese, English, or other languages.

①Material Hopper

1.According to different packaging machines, we provide single bucket and double bucket silos, connecting the elevator and

packaging machine. 2..Customization is also available

packaging machine. 2..Customization is also available

②Elevator

1According to the actual site conditions, provide options for inclined and vertical elevators. 2.According to appearance,divided

into upright elevators and inclined elevators 3.Can choose the corresponding elevator based on the specific material. 4.Support

customization

into upright elevators and inclined elevators 3.Can choose the corresponding elevator based on the specific material. 4.Support

customization

③The Traction machine

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for

producing PET plastic containers and bottles in all shapes

producing PET plastic containers and bottles in all shapes

④The Bending machine

1.Fully automatic towing machine, automatically towing bags to the sewing machine for packaging, no need for manual assistance,

saving labor

saving labor

2.Support customization

⑤The sewing machine

1.Provide fully automatic photosensitive sewing machine with built-in photoelectric sensing probe, automatic packaging and

pneumatic thread cutting, saving manpower and improving packaging efficiency

pneumatic thread cutting, saving manpower and improving packaging efficiency

2.Support customization

⑥The bag Kicker

1.Push the upright packaging bag over with the bag pushing rod, and under the joint action of the bag dumping plate and the

conveyor belt, lay it flat and turn it towards the conveyor. 2. The automatic bag turning drum is used to cooperate with the bag

turning process after the bag is dumped 3.Support customization

conveyor belt, lay it flat and turn it towards the conveyor. 2. The automatic bag turning drum is used to cooperate with the bag

turning process after the bag is dumped 3.Support customization

⑦Slope Conveyor

1.Transport the materials smoothly to the shaping area and decide whether to install them based on the actual site conditions

2.Support customization

2.Support customization

⑧Sorting platform

1.Packaging material shaping platform, adjust the material to be flat and prepare for the final work of the robotic arm

2.Support customization

⑨Robot Arm Palletizer

1.According to production needs, we provide customers with high-level palletizing machines, column palletizing machines, and

robotic arm palletizing machines for selection

robotic arm palletizing machines for selection

2.Support customization

1.What's the order process?

1)Inquiry---provide us all clear requirements (total qty and package details).

2)Quotation---official quotation from with all clear specifications from our professional team.

3)Marking Sample --- confirm all quotation details and the final sample.

4)Production---mass production.

5)Shipping---by sea or by air.

2.What terms of payment you use?

As for the payment terms,it depends on the total amount.

3.How do you ship the products?

By Sea ,By Air ,By courier, TNT , DHL, Fedex, UPS Etc. It is up to you .

4.What is the average delivery time?

Sample usually takes about 10-20days depending on product type. Bulk order usually takes about 35 days.

5.How would I get a price list for a wholesaler ?

Please e-mail us, and tell us about your market with MOQ for each order. We would send the competitive price list to you ASAP.

1)Inquiry---provide us all clear requirements (total qty and package details).

2)Quotation---official quotation from with all clear specifications from our professional team.

3)Marking Sample --- confirm all quotation details and the final sample.

4)Production---mass production.

5)Shipping---by sea or by air.

2.What terms of payment you use?

As for the payment terms,it depends on the total amount.

3.How do you ship the products?

By Sea ,By Air ,By courier, TNT , DHL, Fedex, UPS Etc. It is up to you .

4.What is the average delivery time?

Sample usually takes about 10-20days depending on product type. Bulk order usually takes about 35 days.

5.How would I get a price list for a wholesaler ?

Please e-mail us, and tell us about your market with MOQ for each order. We would send the competitive price list to you ASAP.

Похожие товары

Оптовая продажа авто высокоскоростная машина для упаковки хрустящего риса

Фабрика YB полностью автоматическая 1 г 5 круглая форма чайный стручок мелкий травяной чай гранулы упаковочная машина для чайных Пакетиках

Машина для подсчета капсул и розлива полуавтоматическая машина трав взрослых

200 777,14 ₽

Низкая стоимость мешка Автоматическое Гранулы Пищевые сахар гранулированный упаковочная машина

автоматическая Многофункциональный упаковочная машина для кондитерских изделий

Автоматический шприц поток жидкости фруктовый сок молоко упаковочная машина цена мешок

Овация эффективности 3D Прозрачная пленка упаковочная машина

Новые поступления

Новинки товаров от производителей по оптовым ценам

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $

Съемная пластиковая ручка штукатурка строительный инструмент для отделки бетона с помощью меток

SHIDU U30 двойной беспроводной Перезаряжаемый Профессиональный UHF микрофон караоке с

39,90-57,40 $

1688 закупка Taobao дропшиппинг агент по покупке онлайн-покупки Китай в Испания Румыния Литва от двери до ddp servic

1 $

OEM стираемая зеленая пластиковая клипса с держателем для ручки магнитная футбольная тренировочная

2-2,80 $