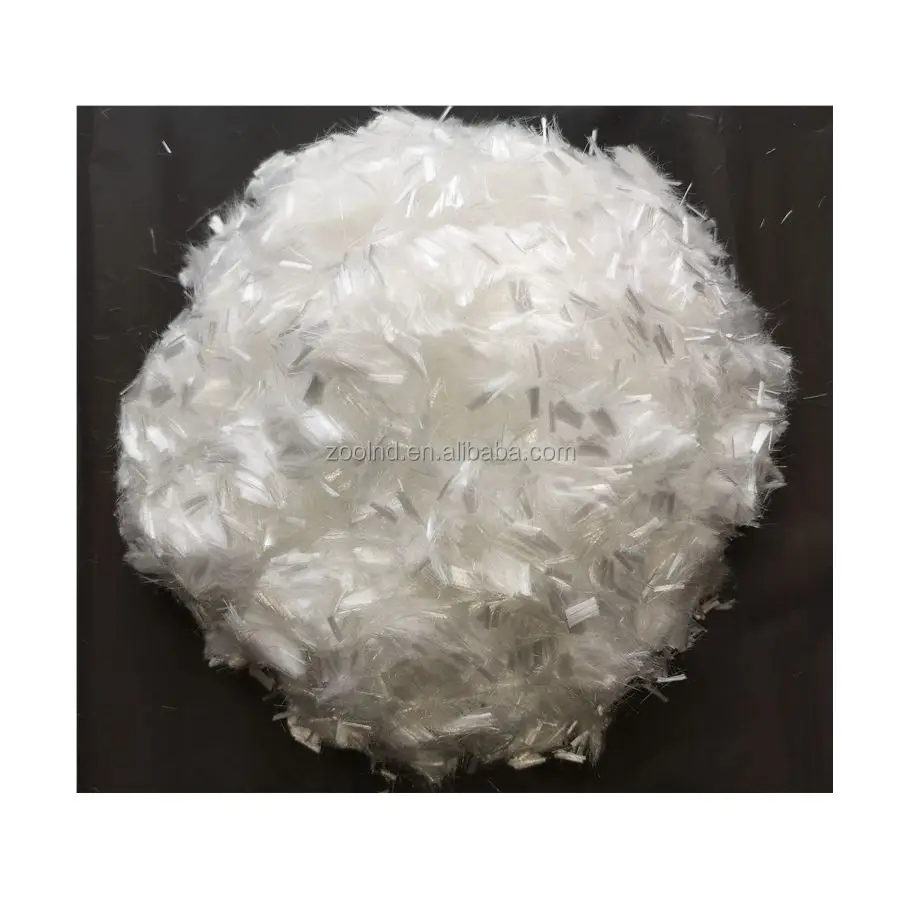

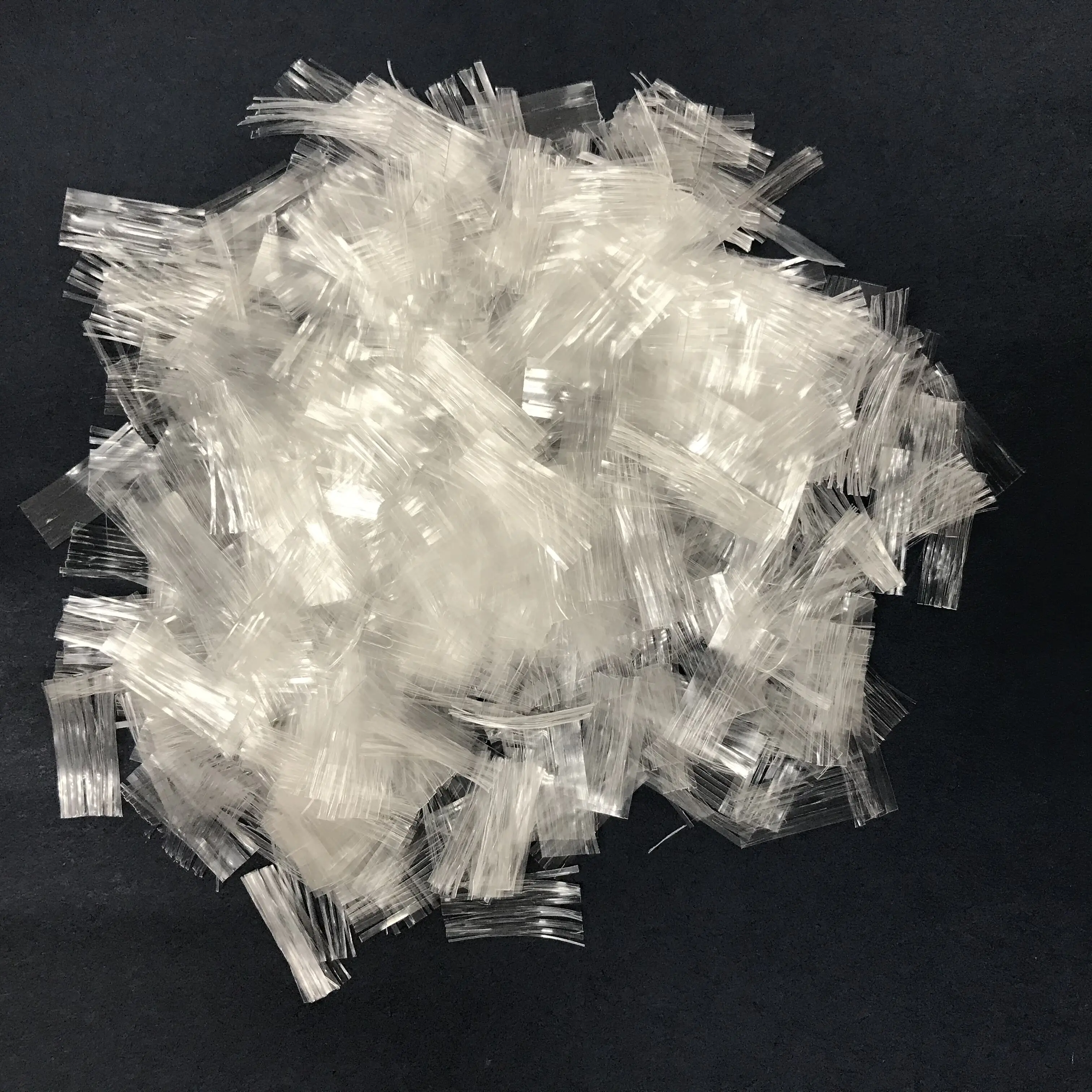

18 мм синтетическое полипропиленовое волокно для бетона высокопроизводительный строительный материал

- Категория: >>>

- Поставщик: Tengzhou Junchi Textile Co. Ltd.Tengzhou Ltd.

Сохранить в закладки 1601341032782:

Описание и отзывы

Характеристики

Raw Material | Polypropylene |

Type | Multifilament |

Fiber Dia | 10-45um |

Tensile Strength | ≥550Mpa |

Size | 3-48mm |

Crack Elongation | 15-25% |

Density | 0.91g/cm3 |

Melting Point | 160---170℃ |

Resistance to Acid, Alkali | Strong |

Water Absorbency | No |

Pp Fiber is also called engineering fiber, concrete fiber, anti-cracking fiber, synthetic fiber or plastic fiber.

Mixing pp fiber into concrete or mortar can control microcrack , which caused by plasticity contraction, air shrinkage or temperature change.

Packing

With years of export experience along with excellent quality, advanced services and competitive prices,

we has won numerous customers' trust and support.With years of export experience along with excellent quality, advanced services and competitive prices, we has won numerous customers' trust and support.

Delivery

600g/ bag, 900g/ bag, 1000g/ bag, paper bag, plastic bag or Water-soluble bag

1*20ft can be loaded 7000-12000kgs, 1*40HQ can be loaded 18000-24000kgs, it depend on the

packing method.

10 days after TT 30% advanced or LC at sight

PP Wave Fiber

PP Twisted Fiber

Plastic-steel fibre

Junchi® Fibre is a monofilament polypropylene fibre for use in concrete to reduce the incidence of

plastic shrinkage cracking. Junchi® Fibre increases the strain capacity of the fresh concrete therefore reducing plastic cracking.

pp fiber construction technology:

1.According to the volume of concrete, in accordance with the requirements for mixture ratio (or suggested dosage) to calculate fiber dosage.

2.After building stones of sand is ready, add the pp fiber. Recommend to use the forced mixer.

3.Add the pp fiber and aggregate into the mixer.But notice: fiber must been added between the aggregate,dry mixing 30s,add cement and water,wet mixture 30s, in order to make the fiber dispersed adequately.

4.Stir after the completion of the random sampling, such as fiber has evenly dispersed into monofilament, concrete can be put into use, if you still have bunch of fiber is extended mixing time 20-30 seconds, then concrete can be used.

5.Add fiber concrete with normal concrete construction and maintenance process is exactly the same.

Похожие товары

Заводское полипропиленовое волокно вместо стального волокна для строительства полипропиленового

Высокая прочность PP моноволокна бетонное волокно 12 мм полипропиленовое

Бетонное волокно PP материал моноволоконное 3 мм 6 9 19

Искусственное волокно Сетчатое полипропиленовое штапельное с уникальной технологией

Горячее надувательство химическое полипропиленовое штапельное волокно с низким запахом для нетканого материала

Синтетическое серое 1 5d * 38 мм огнестойкое полипропиленовое волокно

3 мм высокодисперсионные микро полипропиленовые волокна для цементного раствора FD9130 PP монофиламентные

Новые поступления

Новинки товаров от производителей по оптовым ценам