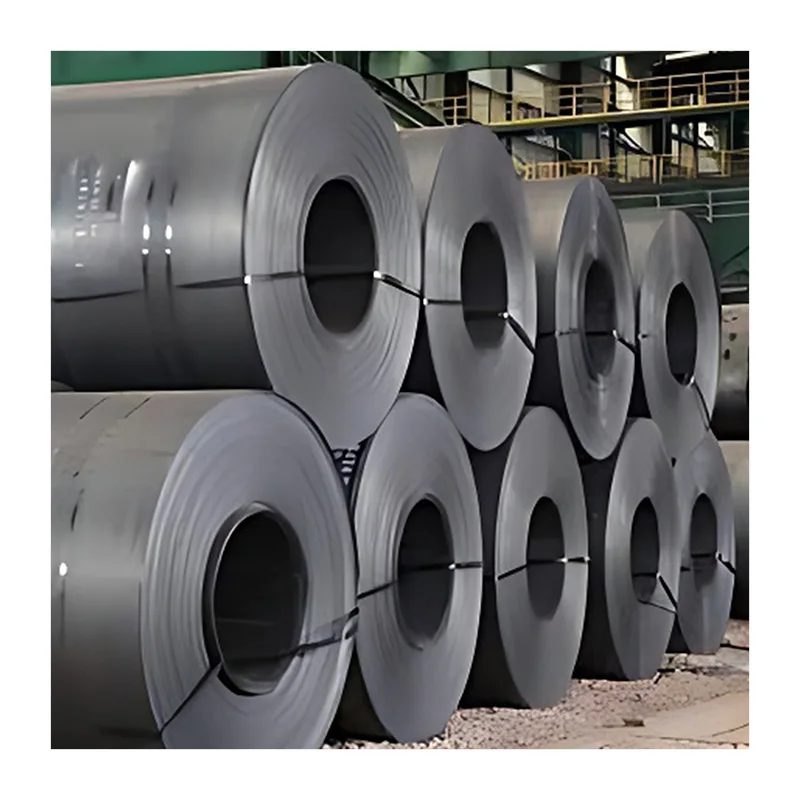

Класс 12 мм 16 мс углеродистая железная катушка горячекатаная стальная Astm A284 класс D Ms из мягкой стали

- Категория: >>>

- Поставщик: Tianjin Maidal New Material Technology Co. Ltd.Tianjin Ltd.

Сохранить в закладки 1601342062829:

Описание и отзывы

Характеристики

Please click here to send the quantity and specifications of the product for the latest quotation, which can support customization

Specification

Product Name | Carbon Steel Coil |

Type | Coil/Sheet/Plate/Strip |

Thickness | 0.12-6.00mm,or customer's requirement |

Surface | Mild steel plain finish, hot dip galvanized, color coated, ect. |

Internatioanal Standard | ISO 9001-2008 / ISO 630 / JIS / ASTM2.0mm-6.0mm |

Standards | ASTMA53/ASTM A573/ASTM A283/Gr.D/BS1387-1985/ GB/T3091- 2001,GB/T13793-92, ISO630/E235B/JIS G3101/JIS G3131/JIS G3106/ |

Materials | Carbon steel :Q195-Q420 Series,SS400-SS540 Series,S235JR-S355JR Series,ST Series,A36-A992 Series,Gr50 Series,etc |

Width | 600mm-1500mm, according to customer's requirement |

ID | 508mm/610mm |

Coil Weight | 3-20 metric ton per coil |

Package | clients' requirement and Standard export sea-worthy packing |

Another Name | Hot rolled mild steel I beam , I beam , H beam ,steel beam ,beam |

MOQ | 1tons.We also can accept sample order. |

Shipment time | Within 7-15 workdays after receiving deposit or L/C |

Products Description

Carbon Steel Coil

Carbon steel coils are coils made of carbon steel with a carbon content of 0.0218%-2.11%. There are mainly Q235, Q345, Q235B and other materials. It has high strength, hardness and good toughness, can withstand greater pressure, and is easy to perform cutting, welding, bending and other processing. Mainly used in construction, manufacturing and transportation fields, such as building bridges, making machinery, railway tracks, etc.

Product Advantages

The raw materials are easy to obtain, the production process is not complicated, the price is relatively affordable, and it is more practical in projects with limited budgets. Carbon can be strengthened and has good strength after treatment. It can be used for structural purposes such as supports and bearings. It has good plasticity and weldability, can be processed in many ways, and is convenient for manufacturing various products.

Product Display

Carbon Structural Steel, it is a kind of carbon steel. The carbon content is about 0.05% ~ 0.70%, some may be as high as 0.90%. It can be divided into ordinary carbon structural steel and high quality carbon structural steel. Mainly used for railway, bridge, all kinds of construction engineering, the manufacture of various metal components bearing static load and mechanical parts and general welding parts which are not important and do not need heat treatment.

Workmanship Process

Tianjin Mydal New Materials Technology Co., Ltd was established in 1997. Located in Liaocheng City, Shandong Province, the largest steel industry park in northern China, we specialize in the production and sales of processed products such as steel coils, steel bars, angle steels, steel sheet piles, H-beams, I-beams, and U-beams. The products mainly extend to five series: sheet metal, belts, pipes, rods, and profiles. We have obtained ISO9001:2000 quality system certification, SGS, ROSH, TUV, and REACH certification. We have production lines for cold rolling, hot rolling, etc. Testing equipment and techniques such as heat treatment chemical analysis, metal halide detection, physical testing, non-destructive testing, etc., as well as imported physical and chemical testing equipment such as full spectrum direct reading spectrometer, can quickly and accurately perform chemical analysis on various metal materials. Produced according to American ASTM standards, Japanese JIS standards, German DIN standards, British BS standards, and other standards. At the same time, we can customize and develop new products based on customers' actual applications, providing products that meet different cost and performance requirements. The company has cooperated with more than 20 well-known steel mills in China and established modern large-scale outdoor and indoor warehouses with a stock of 20000 tons of goods. Our customer base covers various provinces and cities across the country, with over 100 long-term and stable cooperative clients. We warmly welcome and look forward to working with you!

Product Application

Packaging and Transportation

Certifications

FAQ

1.Q:What is a forged shaft?

3.Q:Material selection for forged shafts?

A:The materials used for forging shafts are mainly carbon steel and alloy steel of various compositions, followed by aluminum, magnesium, copper, titanium and their alloys.

4.Q:What are the process flows for forging shafts?

A:Taking hot die forging as an example, the general sequence is: blanking, heating, roll forging, die forging, trimming, punching, correction, intermediate inspection, heat treatment of forgings, cleaning, correction and inspection.

5.Q:What are the classifications of forging temperatures?

A:According to the different forging temperatures, it can be divided into hot forging (above 800℃), warm forging or semi-hot forging (between 300-800℃) and cold forging (performed at room temperature).

A:Forged steel shafts are created through a manufacturing process that involves the shaping of the shaft Forgings using localized compressive forces.

2.Q:What are the advantages of forged shafts?

A:Forging shafts can improve the metal's organizational structure and mechanical properties, ensuring that the parts have good mechanical properties and a longer service life.

A:Forging shafts can improve the metal's organizational structure and mechanical properties, ensuring that the parts have good mechanical properties and a longer service life.

3.Q:Material selection for forged shafts?

A:The materials used for forging shafts are mainly carbon steel and alloy steel of various compositions, followed by aluminum, magnesium, copper, titanium and their alloys.

4.Q:What are the process flows for forging shafts?

A:Taking hot die forging as an example, the general sequence is: blanking, heating, roll forging, die forging, trimming, punching, correction, intermediate inspection, heat treatment of forgings, cleaning, correction and inspection.

5.Q:What are the classifications of forging temperatures?

A:According to the different forging temperatures, it can be divided into hot forging (above 800℃), warm forging or semi-hot forging (between 300-800℃) and cold forging (performed at room temperature).

Похожие товары

Большой запас Ss400 Q235 Q345 рулоны из железной стали горячекатаный рулон углеродистой холоднокатаный лист Dc01

490,00-550,00 $

Арматура из углеродистой стали HRB500 HRB 400 Высококачественная арматура 8 мм/10 мм/12 мм/14 мм/16 мм/18 мм

285,00-510,00 $

HRB500 HRB 400 Стекловолоконные стальные арматурные стержни деформированные железные

285,00-510,00 $

Горячекатаная черная катушка из мягкой углеродистой стали Q195-Q345 St37-A36 St52 S235jr для кровельных вилл парки HRC листовой Железный рулон

500,00-550,00 $

Разнообразная технология обработки нескользящей дренажной коррозионностойкой стальной сетки

Контрольная пластина верхний лист стальная контрольная обеспечиваемая различными образцами стержней

483,00-584,00 $

Singapore DIC оцинкованная бетонная стальная решетка с рамой для бордюрного стока

37,00-38,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $