Массовая продажа черные кольца 70 Shore X FKM fffkm силиконовые NBR резиновые 40*55*10 Размер от китайских производителей

- Категория: >>>

- Поставщик: Hebei Zhishuo Trading Co. LtdHebei Ltd

Сохранить в закладки 1601348534650:

Описание и отзывы

Характеристики

Product Description

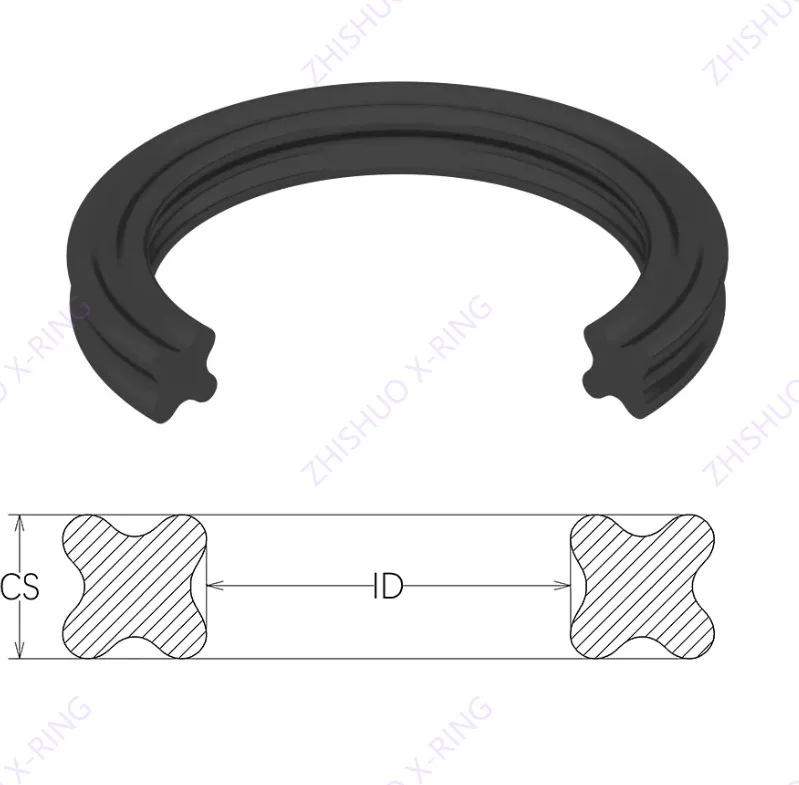

X RING

X-ring is suitable for installation in all kinds of mechanical equipment, in the specified temperature, pressure, as well as

different liquid and gas medium, at rest or motion of the sealing effect. In machine tools, ships, automobiles, aerospace

equipment, metallurgical machinery, chemical machinery, engineering machinery,construction machinery, mining machinery, petroleum

machinery, plastic machinery, agricultural machinery, and all kinds of instruments and meters, a large number of applications of

various types of sealing components.

different liquid and gas medium, at rest or motion of the sealing effect. In machine tools, ships, automobiles, aerospace

equipment, metallurgical machinery, chemical machinery, engineering machinery,construction machinery, mining machinery, petroleum

machinery, plastic machinery, agricultural machinery, and all kinds of instruments and meters, a large number of applications of

various types of sealing components.

product name | X-RING | ||||||

Material | NBR,FKM,SIL/VMQ,EPDM,HNBR,CR,FVMQ,FFKM | ||||||

Hardness | 20°-90°shore A | ||||||

colour | Any colour/Customizable | ||||||

size | Standard parts, non-standard parts, customized | ||||||

In stock | Large inventory of standard parts | ||||||

MOQ | 1000 pcs | ||||||

Certificate | ISO90001/ROHS/LFGB/EN71 | ||||||

package | Inner packing pe bag, outer packing carton | ||||||

delivery time | A: The product is in stock and the delivery time is 3 day. B: The product is out of stock, and the mold is also in stock. Delivery time is 7-9 days. C: The product is out of stock, the mold is out of stock, and the delivery time is 15-25days. (According to the quantity) | ||||||

Product Material

HNBR

Hydrogenated Nitrile /Highly Saturated Nitrile(HNBR):ADAPTIVE

TEMPERATURE:40℃~150'C

COLOR :Black and any color

PERFORMANCE:Better temperature

resistance,weather resistance, oil

resistance, used fornew R-134A refrigerant

system seals

TEMPERATURE:40℃~150'C

COLOR :Black and any color

PERFORMANCE:Better temperature

resistance,weather resistance, oil

resistance, used fornew R-134A refrigerant

system seals

EPDM

Ethtlene propylene Rubber(EPDM):ADAPTIVE

TEMPERATURE:-54C~150℃C0LOR :Black and any color

PERFORMANCE:Heat resistance, ozone,aging,

stability is very good.

TEMPERATURE:-54C~150℃C0LOR :Black and any color

PERFORMANCE:Heat resistance, ozone,aging,

stability is very good.

PU

Polyurethane Rubber(PU):ADAPTIVE

TEMPERATURE:-45℃~90C

COLOR :Black and any color

PERFORMANCE :Widely used in in dustrial parts, especially in high voltage charge system.

COLOR :Black and any color

PERFORMANCE :Widely used in in dustrial parts, especially in high voltage charge system.

FKM/FPM

Fluoro Carbon Rubber(FKM/FPM):ADAPTIVE

TEMPERATURE:-20℃~260℃

COLOR :Black and any color

PERFORMANCE : Widely used in automobile,b products, chemical parts.

COLOR :Black and any color

PERFORMANCE : Widely used in automobile,b products, chemical parts.

Comparison of X-ring and O-ring

1. Sealing effect

O-ring: It shows good sealing performance under standard working conditions, but may leak under extreme working conditions (such as high pressure, high temperature, high speed rotation).

X-shaped seal: Due to its unique four-lip design and lubrication chamber, X-shaped seal shows better sealing effect under complicated working conditions. Experimental data show that under the same conditions, the leakage rate of X-shaped seal is much lower than that of O-shaped seal.

X-shaped seal: Due to its unique four-lip design and lubrication chamber, X-shaped seal shows better sealing effect under complicated working conditions. Experimental data show that under the same conditions, the leakage rate of X-shaped seal is much lower than that of O-shaped seal.

2. Friction resistance

X-shaped seals: due to the design of the lubrication chamber, X-shaped seals in the reciprocating movement of the frictional resistance is smaller, which is conducive to reducing energy loss and prolonging the service life.

3. Temperature and pressure resistance

O-shaped sealing ring: temperature range and pressure resistance depends on the selected material, but in general, its temperature range is wide, pressure resistance is moderate.

X-shaped seals: also have a wide temperature range, and due to the advantages of structural design, their pressure resistance is usually stronger. In some special applications, X-shaped seals can even maintain a stable sealing effect under extreme high pressure.

X-shaped seals: also have a wide temperature range, and due to the advantages of structural design, their pressure resistance is usually stronger. In some special applications, X-shaped seals can even maintain a stable sealing effect under extreme high pressure.

Product Reviews

Company Profile

Hebei ZhiShuo trading Co., LTD

Hebei ZhiShuo trading Co., LTD is a leading domestic sealing solutions supplier. Our product includes o-ring, custom molded rubber parts, and x-ring.Our products have been successfully applied to various industries such as machinery, mining agriculture, home appliances, automobiles, railway set c. We have professional sales workers, and can support customers' variety of high quality products.Meanwhile, we can also make the products according to customers' requirements. Until now, our products have been well received in the world market and enjoy high reputation. We believe that the sincerity is first and client is the highest. We will serve our customers based on Honesty and High Quality Products .We will always achieve the best for you!Sincerely hope to build good and long-term cooperation with more and more domestic and foreign friends!

Certifications

Product Certificates

We have also obtained a number of international certifications, including CE certification, ROHS certification, GS certification and DOT certification.Meet various customer requirements

Packaging

Packaging

We cooperate with many logistics companies to ensure that the logistics prices are advantageous and the goods are delivered to the designated location safely and quickly.

FAQ

Q1. What is the payment term?

A: We accept a T/T 30% deposit and a 70% balance of a current bill of lading or a letter of credit.

Q2. What is the normal delivery time for product orders?

A: The average delivery time of the sample is 1-2 weeks. If the mold production is involved, the delivery cycle of the production mold is 10 days, and the average production time after the sample is approved is 1-2 weeks.

Q3. What is your standard packaging?

A: All goods will be packed in PE bags and then packed in cartons and filled with trays. Special packaging methods are accepted when needed, but charges may apply.

Q4. Which certificate do you have?

A1: we have passed ISO, still applying for more patents.

Q5: How to check the quality of bulk orders?

A1: Our inspection procedures include, first inspection/patrol inspection/initial inspection/full inspection/shipment inspection.

A2: We provide quality certification to all customers before delivery, such as measurement reports, material data sheets, etc.

A3: We accept third party inspections such as SGS, TUV, INTERTEK, BV, etc.

A2: We provide quality certification to all customers before delivery, such as measurement reports, material data sheets, etc.

A3: We accept third party inspections such as SGS, TUV, INTERTEK, BV, etc.

Q6: How do I choose a raw compound for my application?

A: With years of experience in using a variety of materials, we can help you choose the material that best suits your needs,

keeping in mind the cost of materials.

keeping in mind the cost of materials.

Q7: Can you provide materials of different colors?

A: Yes, we can produce custom molded rubber and silicone rubber products in different colors. Color codes are required when ordering.

Q8: From which side can you produce which materials?

A: NBR, EPDM, silicone, FKM, NEOPRENE (CR), NR, IIR, SBR, ACM, AEM, fluorosilicon (FVMQ), FFKM, liquid silica gel, and the like.

Похожие товары

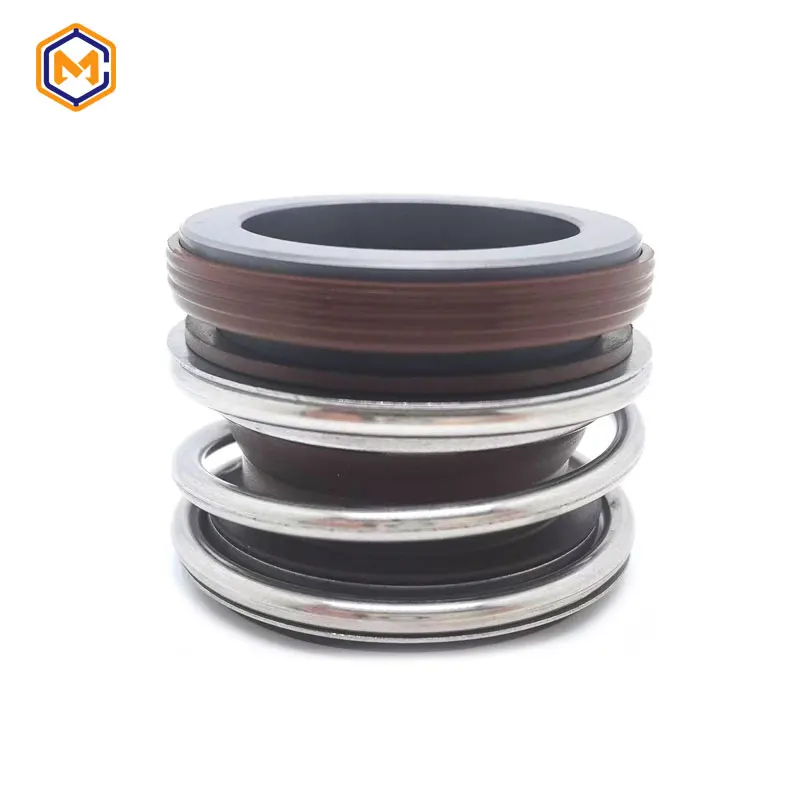

Механическое уплотнение 40 мм/механический уплотнительный водяной насос/кран типа Джона 109 MG1 механическое масляного уплотнения насоса

5,00-7,00 $

Сменный кран John R3 155-10-40mm механическое уплотнение насоса

1,60-3,00 $

Автомобильные подшипники Угловой шаровой подшипник 3207A-2Z 3208A-2RS 3210A-2RS

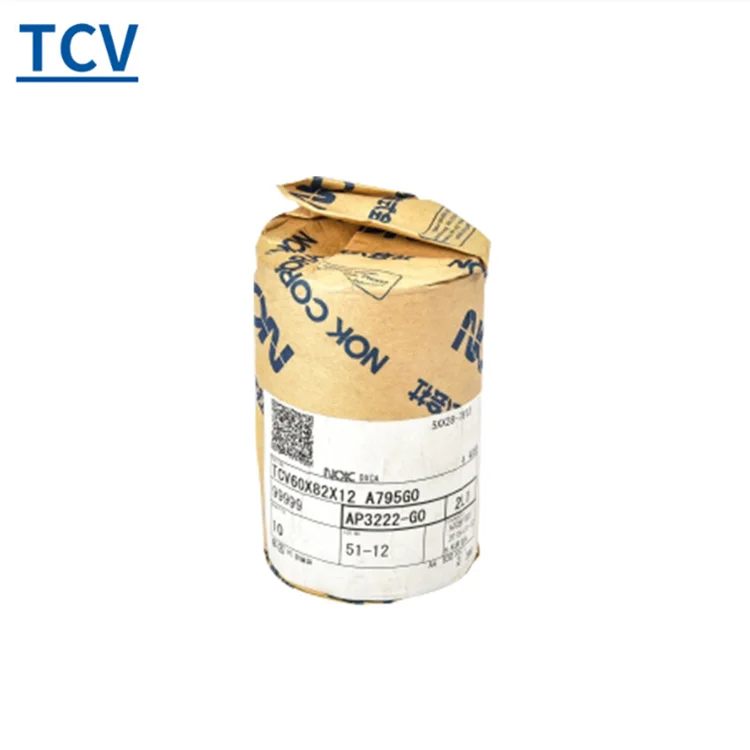

Япония N O K AP0279E0 TCV 10*25*7 NBR сальник высокого давления для гидравлического насоса двигателя

0,50-1,00 $

Оптовая продажа высокое качество UC200 серии длительный срок службы малошумный опорный подшипник для автомобильного трактора

Лидер продаж 45*68*12 APPLT для насоса Kawasaki K3V112 сальник высокого давления двигателя TCN style

2,14-2,86 $

Автомобильные подшипники Угловой шаровой подшипник 3207A-2Z 3208A-2RS 3210A-2RS

Новые поступления

Новинки товаров от производителей по оптовым ценам

Уличная Водонепроницаемая светодиодная лампа IP65 E27 фитинг для фермы патрон лампы со шнуром праздничная лента с колпачком ламп на солнечной батарее

6-8 $

Дезодоратор для домашних животных

4,70-8 $

Профессиональный пневматический гравировальный молоток

22,73-45,45 $

Специальные продажи экстремальное бездорожье Unimog Merce-des-Benz U530

6 000 $

Запасные части для мотоциклов сила 1 импульсная

Беспроводной велосипедный Спидометр Одометр ЖК-Смарт-подсветка

6,40-6,80 $

Вакуумный выключатель против сифон обратный клапан с

Оптовая продажа мужские футболки оверсайз с графическим рисунком 100% футболка премиум-класса хлопковая Футболка логотипом принтом на заказ без рисунка

4,85-7,10 $