Индивидуальные высокопрочные тормозные роторы и маховики Чугунные компоненты автомобильной подвески из стали цинкового сплава

- Категория: >>>

- Поставщик: Ald Precision Manufacturing Co. Ltd.Ald Ltd.

Сохранить в закладки 1601348856614:

Описание и отзывы

Характеристики

ALD Precision Manufacturing Co., Ltd. is a trusted leader in the casting industry with 30 years of experience. We specialize in

producing ductile iron, gray iron, and vermicular iron castings, as well as high-precision machined parts for industries such as

automotive, rail transportation, industrial machinery, and renewable energy. Production Capacity Casting Capacity: With an annual

production capacity of 30,000 tons of castings, we can meet both small-batch and large-scale production requirements. Machining

Capability: Our advanced workshop houses over 100 CNC machining centers and precision equipment, ensuring exceptional machining quality and efficiency. Unique Vertical Machining Centers: Our self-developed vertical machining centers are one-of-a-kind in the market, offering unparalleled performance and reliability.

producing ductile iron, gray iron, and vermicular iron castings, as well as high-precision machined parts for industries such as

automotive, rail transportation, industrial machinery, and renewable energy. Production Capacity Casting Capacity: With an annual

production capacity of 30,000 tons of castings, we can meet both small-batch and large-scale production requirements. Machining

Capability: Our advanced workshop houses over 100 CNC machining centers and precision equipment, ensuring exceptional machining quality and efficiency. Unique Vertical Machining Centers: Our self-developed vertical machining centers are one-of-a-kind in the market, offering unparalleled performance and reliability.

What We Offer

Automotive Components: Engine brackets, shock absorber

bases, support shafts, and more. Reducer Parts: Gearbox housings, bearing seats, and other wear-resistant components. Industrial

Pump Accessories: Pump casings, impellers, and bases. Precision CNC Machining: Customized parts manufactured to client specifications.

bases, support shafts, and more. Reducer Parts: Gearbox housings, bearing seats, and other wear-resistant components. Industrial

Pump Accessories: Pump casings, impellers, and bases. Precision CNC Machining: Customized parts manufactured to client specifications.

Slewing Drive Parts and Other Cast Components: Machine tool accessories, structural parts, and mechanical

components.

components.

Why Choose Us Integrated Solutions: We provide one-stop services, including casting, grinding, CNC machining,

painting, welding, and heat treatment. Certified Quality: ISO9001 and IATF16949 certified, ensuring the highest quality standards.

Market-Leading Clients: Trusted by industry leaders like FAW and CRRC for reliable products and services. Customization Expertise:

Tailored manufacturing to meet your unique requirements. We are committed to delivering high-quality castings and machined parts

to our global customers. Partner with us for innovative solutions and dependable service!

painting, welding, and heat treatment. Certified Quality: ISO9001 and IATF16949 certified, ensuring the highest quality standards.

Market-Leading Clients: Trusted by industry leaders like FAW and CRRC for reliable products and services. Customization Expertise:

Tailored manufacturing to meet your unique requirements. We are committed to delivering high-quality castings and machined parts

to our global customers. Partner with us for innovative solutions and dependable service!

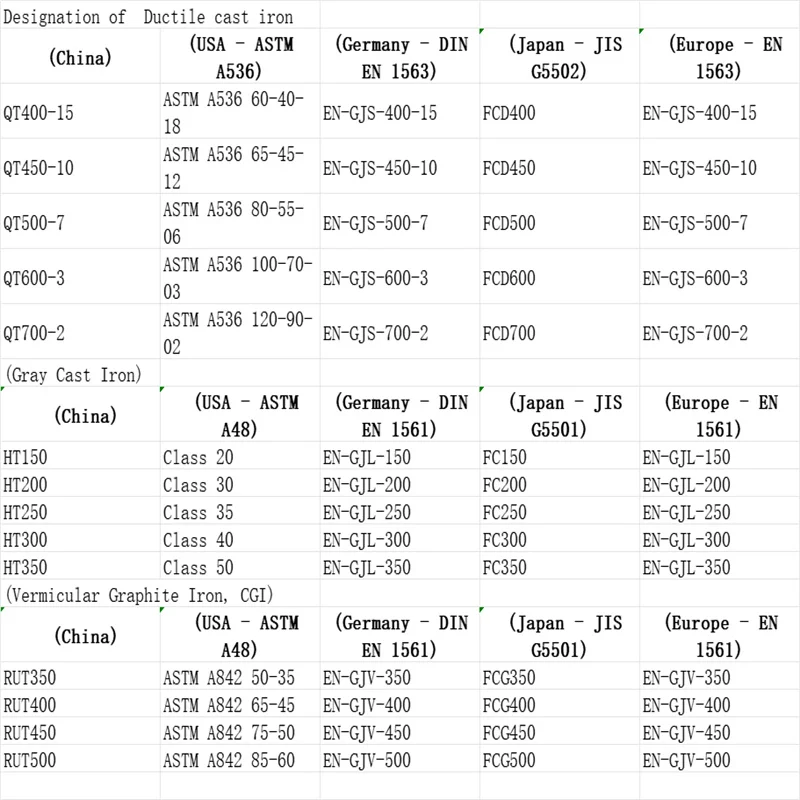

Designation of Ductile cast iron | ||||

(China) | (USA - ASTM A536) | (Germany - DIN EN 1563) | (Japan - JIS G5502) | (Europe - EN 1563) |

QT400-15 | ASTM A536 60-40-18 | EN-GJS-400-15 | FCD400 | EN-GJS-400-15 |

QT450-10 | ASTM A536 65-45-12 | EN-GJS-450-10 | FCD450 | EN-GJS-450-10 |

QT500-7 | ASTM A536 80-55-06 | EN-GJS-500-7 | FCD500 | EN-GJS-500-7 |

QT600-3 | ASTM A536 100-70-03 | EN-GJS-600-3 | FCD600 | EN-GJS-600-3 |

QT700-2 | ASTM A536 120-90-02 | EN-GJS-700-2 | FCD700 | EN-GJS-700-2 |

(Gray Cast Iron) | ||||

(China) | (USA - ASTM A48) | (Germany - DIN EN 1561) | (Japan - JIS G5501) | (Europe - EN 1561) |

HT150 | Class 20 | EN-GJL-150 | FC150 | EN-GJL-150 |

HT200 | Class 30 | EN-GJL-200 | FC200 | EN-GJL-200 |

HT250 | Class 35 | EN-GJL-250 | FC250 | EN-GJL-250 |

HT300 | Class 40 | EN-GJL-300 | FC300 | EN-GJL-300 |

HT350 | Class 50 | EN-GJL-350 | FC350 | EN-GJL-350 |

(Vermicular Graphite Iron, CGI) | ||||

(China) | (USA - ASTM A48) | (Germany - DIN EN 1561) | (Japan - JIS G5501) | (Europe - EN 1561) |

RUT350 | ASTM A842 50-35 | EN-GJV-350 | FCG350 | EN-GJV-350 |

RUT400 | ASTM A842 65-45 | EN-GJV-400 | FCG400 | EN-GJV-400 |

RUT450 | ASTM A842 75-50 | EN-GJV-450 | FCG450 | EN-GJV-450 |

RUT500 | ASTM A842 85-60 | EN-GJV-500 | FCG500 | EN-GJV-500 |

What we can produce?

ALD Precision Manufacturing Co., Ltd. specializes in a wide range of casting and precision machining products across various

industries. Here is a detailed list of the products we can manufacture, categorized by industry:

1. Automotive Industry

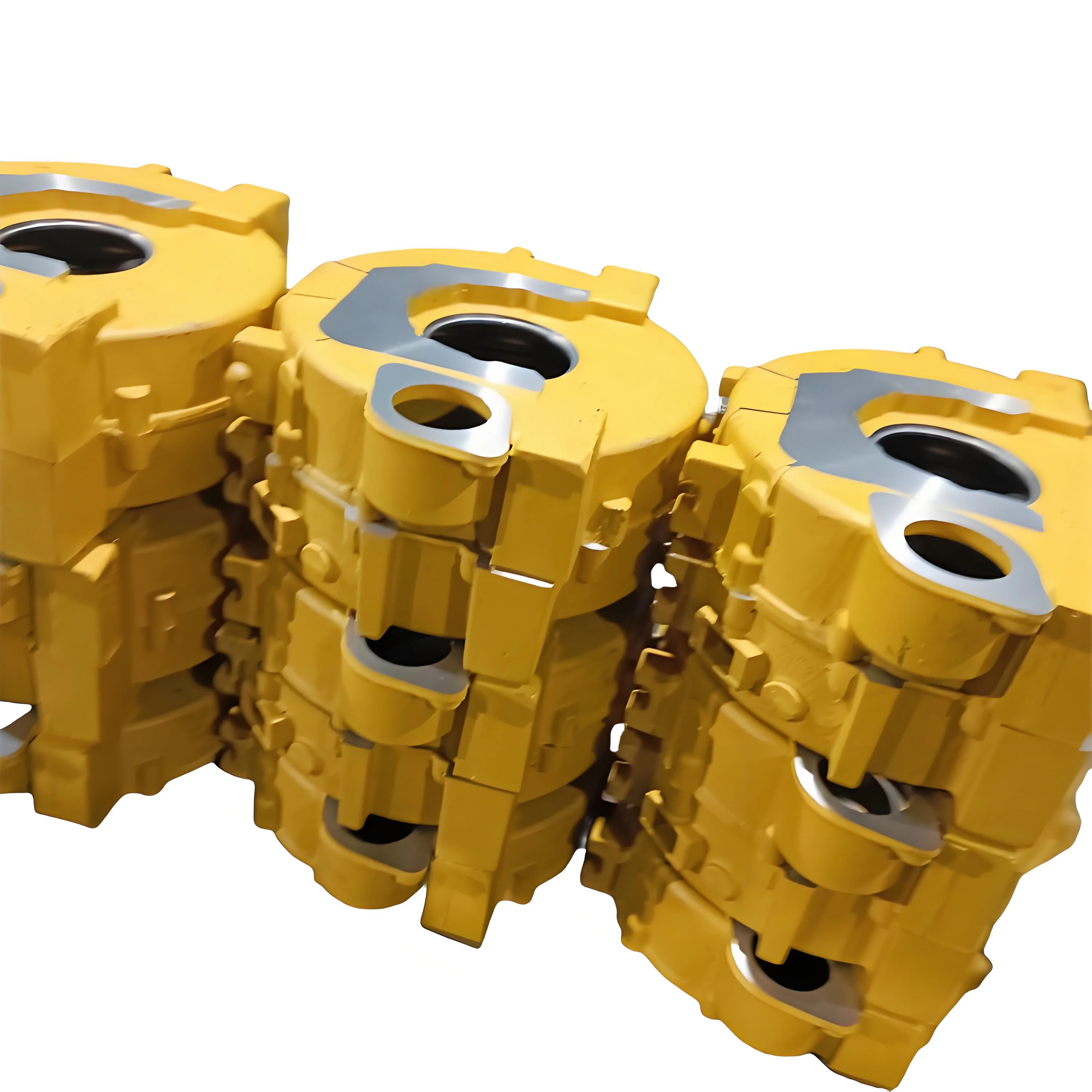

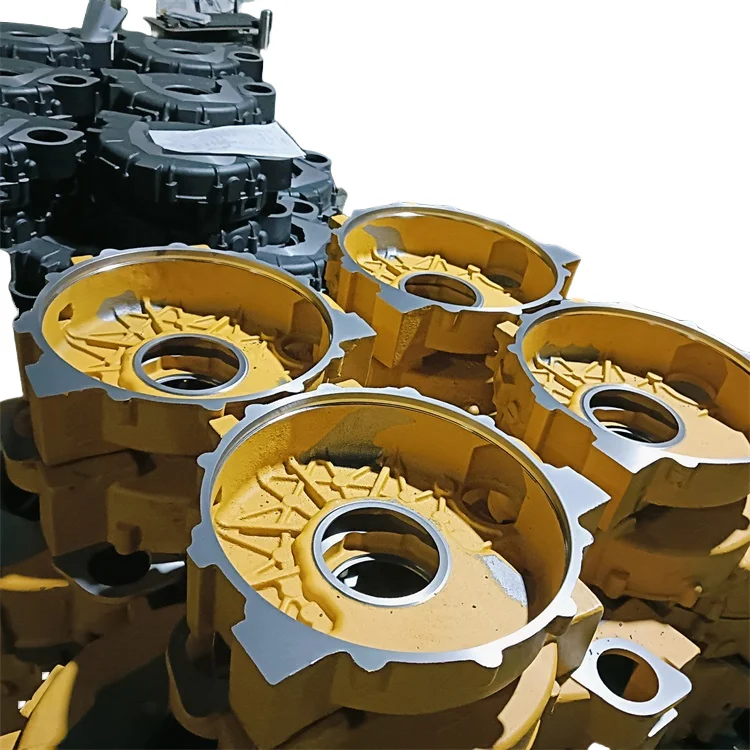

* Brake Discs: Precision-cast and machined brake components for vehicles.

* Flywheels: High-strength, precision-machined flywheels for automotive engines.

* Transmission Components: Including gears, shafts, and other drivetrain components.

* Suspension Parts: Cast components for vehicle suspension systems.

* Chassis Components: Structural castings for car chassis.

* Steering Components: Parts such as steering knuckles and steering arms.

* Differential Cases: Precision casting and machining for differential housings.

2. Rail & High-Speed Rail Industry

* Train Brake Discs: High-performance cast iron components for train braking systems.

* Rail Wheel Hubs: Precision machined hubs for train wheels.

* Axle Sleeves: Cast components for railway axle systems.

* Coupling Parts: Precision cast and machined railway coupling systems.

* Track Components: Parts used in rail track support and alignment.

3. Hydraulic Industry

* Hydraulic Pump Components: Cast and machined parts for hydraulic pump systems.

* Hydraulic Valve Bodies: Precision castings for hydraulic control valves.

* Cylinder Parts: Parts such as cylinders, pistons, and rods for hydraulic machinery.

* Hydraulic Flanges: Components for hydraulic system connections.

4. Construction & Excavation Machinery

* Excavator Accessories: Cast and machined parts for excavator arms, booms, and undercarriages.

* Construction Machine Parts: Components for loaders, bulldozers, and other construction machinery.

* Slewing Drives: Precision castings and machining for slewing drives in excavators and cranes.

* Crawler Tracks: Cast and machined components for construction vehicle tracks.

5. Agricultural Machinery

* Agricultural Equipment Parts: Cast and machined components for tractors, harvesters, and plows.

* PTO Shaft Components: Precision castings for power take-off shafts in agricultural machinery.

* Transmission Parts: Components for the transmission systems in agricultural vehicles.

6. Solar Energy Industry

* Mounting Brackets for Solar Panels: Cast and machined components used in solar panel mounting systems.

* Frame Components: Precision-cast parts for solar panel frames and structures.

* Electrical Enclosures: Cast enclosures for solar energy systems, including junction boxes.

7. Industrial Machinery & Equipment

* Reducer Components: Parts for industrial gear reducers and transmissions.

* Industrial Pump Parts: Precision-cast and machined components for industrial pumps.

* CNC Machined Finishing Products: Finely machined components for various industrial applications.

* Machine Tool Accessories: Cast and precision-machined parts for machine tools and automated machinery.

8. Marine & Offshore Industry

* Marine Engine Components: Parts such as crankcases, cylinder heads, and bearings.

* Offshore Equipment Components: Castings for offshore drilling rigs and equipment.

9. Slewing Drives & Bearings

* Slewing Drives: Custom slewing drives for various applications, including wind turbines, cranes, and heavy machinery.

* Slewing Bearings: Precision cast and machined bearings for rotation systems in various machinery and equipment.

10. General Mechanical Parts

* Precision Cast Parts: Custom mechanical components made to exact specifications.

* Sheet Metal Welded Components: Fabricated parts that require sheet metal welding, machining, and finishing.

* Heat-Treated Castings: Parts that undergo heat treatment processes to improve material properties, such as strength and durability.

11. Machine Tool Accessories

* Spindle Parts: High-precision castings and machined parts for CNC machines.

* Tool Holders: Cast and machined components for holding cutting tools in industrial machines.

* Guide Rails: Precision cast guide rails for machinery.

12. Aerospace Industry

* Aircraft Engine Components: Precision cast and machined parts for aerospace engines.

* Landing Gear Components: Critical castings for aircraft landing gear systems.

13. Sheet Metal Products

* Laser Cut Sheet Metal Components: Precision laser-cut parts for various applications across industries.

* Stamped Sheet Metal Parts: Stamped components for automotive, industrial machinery, and other applications.

* Baked Paint Coated Parts: Sheet metal components with high-quality baked paint finishes for durability and aesthetic appeal.

* Heat-Treated Sheet Metal Parts: Sheet metal components undergoing heat treatment for improved strength and performance.

ALD Precision Manufacturing Co., Ltd. now also provides integrated sheet metal services alongside our casting and machining processes, giving our clients a comprehensive solution from laser cutting to heat treatment and finishing.

industries. Here is a detailed list of the products we can manufacture, categorized by industry:

1. Automotive Industry

* Brake Discs: Precision-cast and machined brake components for vehicles.

* Flywheels: High-strength, precision-machined flywheels for automotive engines.

* Transmission Components: Including gears, shafts, and other drivetrain components.

* Suspension Parts: Cast components for vehicle suspension systems.

* Chassis Components: Structural castings for car chassis.

* Steering Components: Parts such as steering knuckles and steering arms.

* Differential Cases: Precision casting and machining for differential housings.

2. Rail & High-Speed Rail Industry

* Train Brake Discs: High-performance cast iron components for train braking systems.

* Rail Wheel Hubs: Precision machined hubs for train wheels.

* Axle Sleeves: Cast components for railway axle systems.

* Coupling Parts: Precision cast and machined railway coupling systems.

* Track Components: Parts used in rail track support and alignment.

3. Hydraulic Industry

* Hydraulic Pump Components: Cast and machined parts for hydraulic pump systems.

* Hydraulic Valve Bodies: Precision castings for hydraulic control valves.

* Cylinder Parts: Parts such as cylinders, pistons, and rods for hydraulic machinery.

* Hydraulic Flanges: Components for hydraulic system connections.

4. Construction & Excavation Machinery

* Excavator Accessories: Cast and machined parts for excavator arms, booms, and undercarriages.

* Construction Machine Parts: Components for loaders, bulldozers, and other construction machinery.

* Slewing Drives: Precision castings and machining for slewing drives in excavators and cranes.

* Crawler Tracks: Cast and machined components for construction vehicle tracks.

5. Agricultural Machinery

* Agricultural Equipment Parts: Cast and machined components for tractors, harvesters, and plows.

* PTO Shaft Components: Precision castings for power take-off shafts in agricultural machinery.

* Transmission Parts: Components for the transmission systems in agricultural vehicles.

6. Solar Energy Industry

* Mounting Brackets for Solar Panels: Cast and machined components used in solar panel mounting systems.

* Frame Components: Precision-cast parts for solar panel frames and structures.

* Electrical Enclosures: Cast enclosures for solar energy systems, including junction boxes.

7. Industrial Machinery & Equipment

* Reducer Components: Parts for industrial gear reducers and transmissions.

* Industrial Pump Parts: Precision-cast and machined components for industrial pumps.

* CNC Machined Finishing Products: Finely machined components for various industrial applications.

* Machine Tool Accessories: Cast and precision-machined parts for machine tools and automated machinery.

8. Marine & Offshore Industry

* Marine Engine Components: Parts such as crankcases, cylinder heads, and bearings.

* Offshore Equipment Components: Castings for offshore drilling rigs and equipment.

9. Slewing Drives & Bearings

* Slewing Drives: Custom slewing drives for various applications, including wind turbines, cranes, and heavy machinery.

* Slewing Bearings: Precision cast and machined bearings for rotation systems in various machinery and equipment.

10. General Mechanical Parts

* Precision Cast Parts: Custom mechanical components made to exact specifications.

* Sheet Metal Welded Components: Fabricated parts that require sheet metal welding, machining, and finishing.

* Heat-Treated Castings: Parts that undergo heat treatment processes to improve material properties, such as strength and durability.

11. Machine Tool Accessories

* Spindle Parts: High-precision castings and machined parts for CNC machines.

* Tool Holders: Cast and machined components for holding cutting tools in industrial machines.

* Guide Rails: Precision cast guide rails for machinery.

12. Aerospace Industry

* Aircraft Engine Components: Precision cast and machined parts for aerospace engines.

* Landing Gear Components: Critical castings for aircraft landing gear systems.

13. Sheet Metal Products

* Laser Cut Sheet Metal Components: Precision laser-cut parts for various applications across industries.

* Stamped Sheet Metal Parts: Stamped components for automotive, industrial machinery, and other applications.

* Baked Paint Coated Parts: Sheet metal components with high-quality baked paint finishes for durability and aesthetic appeal.

* Heat-Treated Sheet Metal Parts: Sheet metal components undergoing heat treatment for improved strength and performance.

ALD Precision Manufacturing Co., Ltd. now also provides integrated sheet metal services alongside our casting and machining processes, giving our clients a comprehensive solution from laser cutting to heat treatment and finishing.

About our company

ALD Precision Manufacturing Co., Ltd.

With over 30 years of experience in the casting and precision machining industry, ALD Precision Manufacturing Co., Ltd. is a trusted leader in providing high-quality and innovative solutions. Our company specializes in manufacturing custom castings, precision-machined parts, and mechanical assemblies for a wide range of industries, including automotive, rail, renewable energy, and industrial machinery. We pride ourselves on our extensive experience in casting, with four

advanced production lines designed to meet various production needs.

advanced production lines designed to meet various production needs.

These include:

Iron Mold Casting Production Line: Ideal for high-volume orders, this line ensures the production of durable, cost-effective castings with fast turnaround times.

Resin Sand Casting Production Line: Perfect for smaller, high-precision orders or prototypes, this line produces castings with excellent surface finishes and dimensional accuracy.

Static Pressure Casting Production Line: Used for large, heavy castings that require high strength and durability, this line guarantees reliable, high-quality results.

Mechanical Casting Production Line: Specialized for producing mechanical components, including parts for

automotive, pumps, and machinery.

automotive, pumps, and machinery.

At ALD, we utilize state-of-the-art technology, including CNC precision machining, heat treatment, spray painting and surface finishing, to provide the highest quality products to our customers. Our comprehensive

service offering includes everything from casting to precision machining, surface treatment, and final assembly, making us a one-stop solution provider for all your manufacturing needs. Over the years, we have established long-term relationships with major global companies, including industry leaders such as FAW, CRRC, and Hengli. These partnerships highlight our capability to meet the demanding requirements of top-tier companies in the automotive, rail, and industrial sectors.

service offering includes everything from casting to precision machining, surface treatment, and final assembly, making us a one-stop solution provider for all your manufacturing needs. Over the years, we have established long-term relationships with major global companies, including industry leaders such as FAW, CRRC, and Hengli. These partnerships highlight our capability to meet the demanding requirements of top-tier companies in the automotive, rail, and industrial sectors.

FAQ:

1. What industries does your company specialize in?

ALD Precision Manufacturing Co., Ltd. specializes in providing high-quality

casting and precision machining products for industries such as automotive, rail transportation, new energy vehicles, and solar photovoltaic. We supply customized cast iron components and mechanical parts to global leading companies, including Volkswagen, FAW, CRRC, and others.

casting and precision machining products for industries such as automotive, rail transportation, new energy vehicles, and solar photovoltaic. We supply customized cast iron components and mechanical parts to global leading companies, including Volkswagen, FAW, CRRC, and others.

2. What types of products do you primarily produce?

Our main products include ductile iron, gray cast iron, and vermicular cast iron components used in automotive parts, reducer accessories, industrial pump parts, and more. We also offer CNC precision machining, mechanical surface finishing, mechanical baking varnish, welding, and heat treatment services.

3. Do you accept custom orders?

Yes, we specialize in custom production. We provide high-precision casting and machining services tailored

to your specific requirements. Our team will work closely with you to ensure the products meet your exact specifications and quality standards.

to your specific requirements. Our team will work closely with you to ensure the products meet your exact specifications and quality standards.

4. How do you ensure product quality?

With 30 years of casting experience, we use advanced production equipment

and rigorous quality control processes to ensure that every product meets international standards. All products undergo strict testing and quality checks before delivery to ensure they meet customer requirements.

and rigorous quality control processes to ensure that every product meets international standards. All products undergo strict testing and quality checks before delivery to ensure they meet customer requirements.

5. What is your typical lead time?

Our lead time depends on the order quantity and complexity. For standard orders, the typical lead time is 4 to 6 weeks. For customizedproducts, we will discuss the production schedule with you based on specific needs.

6. Do you offer samples?

- Yes, we can provide samples to help you verify the product quality. The delivery time and cost for samples will depend on the complexity and quantity of the products, and we can discuss these details further. 7. How do you ensure production quality for orders? Our quality control team closely monitors the production process to ensure that all products meet the design specifications. Additionally, customers can request third-party inspection reports or arrange for on-site inspections to ensure the quality of the production.

8. What are your payment terms?

We accept various payment methods, including Letters of Credit (L/C), Telegraphic Transfer (T/T), and others.

Payment terms will be negotiated based on the order amount and cooperation details.

Payment terms will be negotiated based on the order amount and cooperation details.

9. Do you provide after-sales service?

Yes, we provide comprehensive after-sales support. If there are any quality issues with the products during use, you can contact our after-sales team, and we will provide solutions or product replacements.

10. How can I get a quote?

Please contact us through Alibaba’s inquiry system ,send us your drawing and quantity, packing requirements. We will send you a detailed quote based on your needs.

1. Who are you? (Market Positioning)

We are ALD Precision Manufacturing Co., Ltd., a high-end supplier specializing in themanufacturing of custom casting and precision machining products. Our market focus is on the export sector, particularly serving the high-end manufacturing needs in industries such as automotive, rail transportation, new energy vehicles, and solar photovoltaic. We are positioned as a reliable, quality-driven supplier for both mid and high-end markets worldwide.

2. What are your strengths? (Company Advantages)

Our core strengths include: Customization: We provide fully tailored solutions, ensuring that

each product meets the specific needs of our customers. Fast Response: With an agile production system and dedicated customer support, we ensure timely responses and efficient order fulfillment. Support for Small-Batch Orders: We are capable of handlingsmall and medium-sized orders, offering flexibility that large manufacturers may not. Advanced Equipment & Facility: Our factory is equipped with state-of-the-art production technology, enabling us to achieve high precision and quality control across all processes. Experienced Workforce: With 30 years of experience in casting production, our team brings deep industry expertise and craftsmanship to every product.

each product meets the specific needs of our customers. Fast Response: With an agile production system and dedicated customer support, we ensure timely responses and efficient order fulfillment. Support for Small-Batch Orders: We are capable of handlingsmall and medium-sized orders, offering flexibility that large manufacturers may not. Advanced Equipment & Facility: Our factory is equipped with state-of-the-art production technology, enabling us to achieve high precision and quality control across all processes. Experienced Workforce: With 30 years of experience in casting production, our team brings deep industry expertise and craftsmanship to every product.

3. Where are your customers located? (Market Target)

We serve a global market, with a primary focus on the automotive, rail transportation, new energy, and solar photovoltaic industries. Our customer base includes manufacturers, suppliers, and distributors, particularly those seeking high-quality, custom-designed mechanical parts and components. We engage directly with factories, OEMs, trade companies, and B2B buyers. Notably, we serve industry-leading companies such as FAW, CRRC, and other top-ranking enterprises across various sectors worldwide.

4. What concerns do your customers have?

Our customers often have concerns regarding: Trust & Professionalism: Customers seek a supplier they can trust to deliver high-quality products on time. Quality Assurance: They need assurance that products meet international standards and pass rigorous quality control. Service & Support: Prompt and responsive communication, post-sale support, and problem resolution are critical for customer satisfaction. Competitive Pricing: While quality is a priority, customers also look for cost-effective solutions that provide value for money. Capacity & Innovation: Customers value our ability to handle large orders while maintaining product innovation and quality. Certification & Industry Standards: Customers prefer working with certified manufacturers that adhere to industry regulations and standards.

Our customers often have concerns regarding: Trust & Professionalism: Customers seek a supplier they can trust to deliver high-quality products on time. Quality Assurance: They need assurance that products meet international standards and pass rigorous quality control. Service & Support: Prompt and responsive communication, post-sale support, and problem resolution are critical for customer satisfaction. Competitive Pricing: While quality is a priority, customers also look for cost-effective solutions that provide value for money. Capacity & Innovation: Customers value our ability to handle large orders while maintaining product innovation and quality. Certification & Industry Standards: Customers prefer working with certified manufacturers that adhere to industry regulations and standards.

5. Why are your products better than others?

Our products stand out due to: Advanced Equipment: We have the most advanced casting production line:Iron Mold casting production line, 55seconds molding, good finish, high yield and technology to ensure precision and high quality in every product. Expertise: With 30 years of casting experience, we have honed our expertise to produce reliable, high-performance components. Certifications: Our products are manufactured according to international quality standards, with certifications that ensure compliance with industry requirements. Industry Reports: We regularly undergo industry inspections and audits, and we can provide comprehensive reports to assure our clients of our product quality.

6. What industries do your products mainly serve?

Our products primarily serve the following industries: Automotive: Custom parts for engines, chassis, and drivetrains. Rail Transportation: Components for trains, high-speed rail, and rail infrastructure. New Energy Vehicles: Parts for electric vehicles (EVs), hybrid cars, and supporting components. Solar Photovoltaic: Precision components for solar energy systems, including supports and mounting systems. Industrial Machinery: Parts

for industrial pumps, reducers, and other heavy machinery.

for industrial pumps, reducers, and other heavy machinery.

Presence: We have expanded our presence globally, meeting international quality standards and certifications,ISO9001,IATF16949

allowing us to support clients in various regions, including Europe, North America, and Asia.

allowing us to support clients in various regions, including Europe, North America, and Asia.

Похожие товары

Промышленное литье литейного чугуна

1 000,00 $

Для аппаратных электромеханических аксессуаров Литье по выплавляемым моделям индивидуальному заказу детали из цинкового алюминия и песка

0,03-0,06 $

Прямая Продажа с завода Высококачественная круглая экструдированная Керамическая ТРУБА

30 000,00-42 000,00 $

Втулка системы подвески

Изготовленный на заказ металлический литейный прецизионный 304 316 нержавеющей стали инвестиционного литья

7,90-8,90 $

Оптовая продажа по индивидуальному заказу литая крышка люка из ковкого чугуна и дренажная решетка

5,00-5,50 $

Горячая распродажа стандартная индивидуальная круглая чугунная крышка люка En124 D400 с рамой

66,00-69,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

OrionStars онлайн-машина для рыбалки и свинга высокоприбыльная монетная игра США оптовая продажа агент с высокой прибылью Разыскивается

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $