Индивидуальные китайские пластиковые пресс формы из АБС силикона

- Категория: >>>

- Поставщик: Weifang Tenggu Intelligent Manufacturing Co. Ltd.Weifang Ltd.

Сохранить в закладки 1601350728767:

Описание и отзывы

Характеристики

Company Profile

The minimum order quantity is 1 piece, ensuring the safety of customer funds, low product prices, quick response to customer requirements, worry free after-sales service, and factory direct sales,Welcome to inquire: 86+15065363330

well appointed

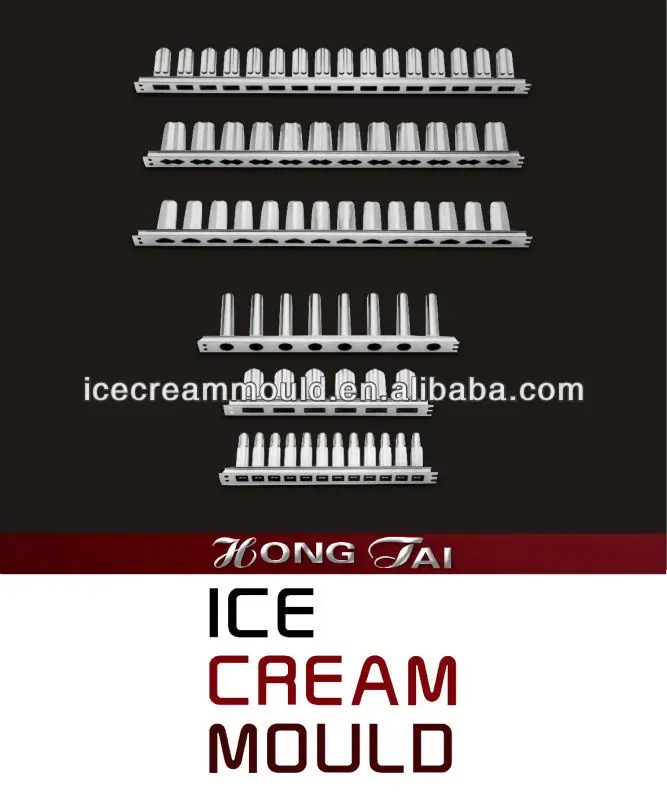

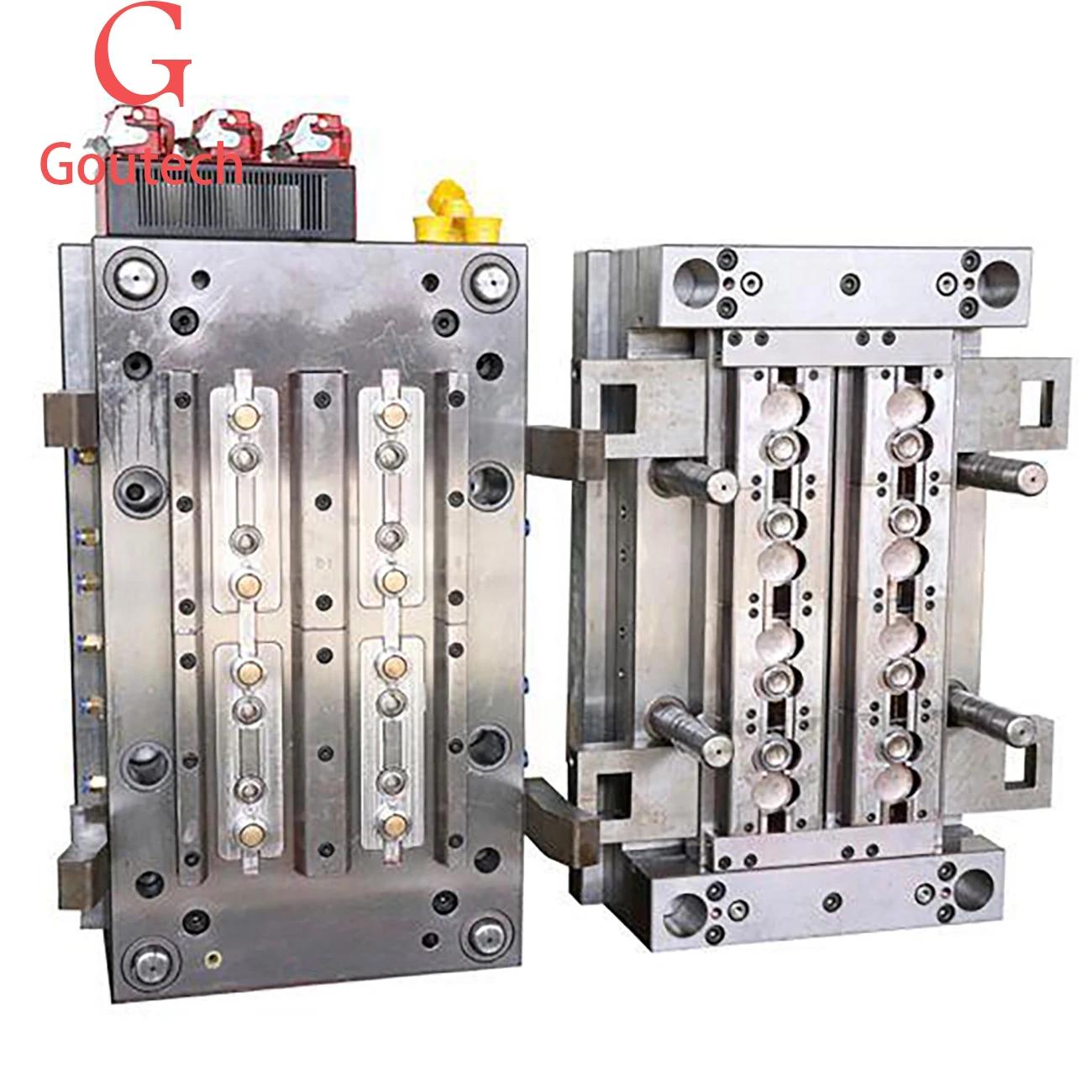

We have dozens of large-scale fireworks machines, CNC machining centers, rocker drills, deep hole drills and other mold equipment to meet customers' different product needs

Durable performance

High quality materials: Our customized precision molds are made of high-quality materials, including P20718h, 738, and S136HZ, ensuring excellent durability and corrosion resistance.

Weifang Tenggu Intelligent Manufacturing Co., Ltd. is a high-tech enterprise specializing in providing one-stop manufacturing services for injection molded products, serving industries such as automotive parts, household appliances, transportation, industrial parts, aviation, medical, etc. We are committed to design, mold, injection molding, spraying, electroplating, carving, printing, assembly, and other fields. With a total investment of 5 million US dollars and a factory area of over 10000 square meters, we will do our best to create a benchmark enterprise for supporting services throughout the entire industry chain. Our products are exported to countries and regions such as North America, Japan, Southeast Asia, and South America. We offer: 1) excellent quality control 2) highly competitive prices 3) advanced technology products 4) the best professional electronic team 5) smooth communication 6) effective OEM&ODM services

Our company has an advanced plastic electroplating production line that can meet the surface treatment needs of plastic products such as chrome plating, gold plating, matte black, and matte finish.

precision

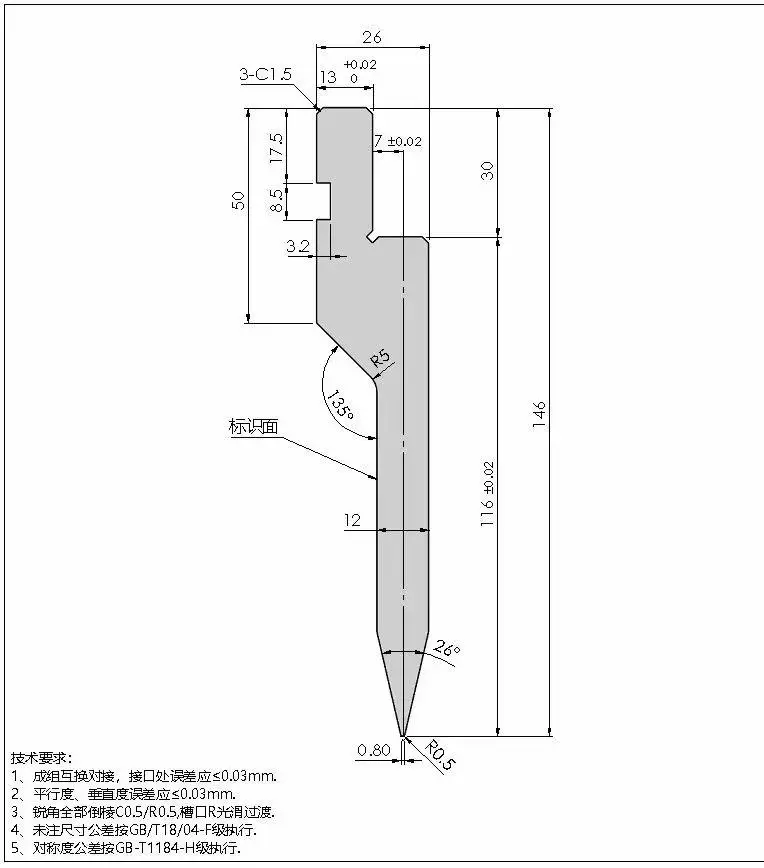

We have 5 professional engineers, and the precision of mold processing can be controlled to 0.05mm

Chinese mold manufacturer specializing in plastic injection molding factory

Starting from the analysis of component design.

2. Provide mold design drawings and DFM reports so that you can understand the status of the mold before manufacturing.

If the product is complex, a moldflow report will also appear.

4. Ensure that the quality of your molds is well controlled in the indoor mold manufacturing workshop.

5. It usually takes 20-40 days to make a mold, and the exact time depends on the part design.

6. Injection molded parts can be made of different materials, such as ABS/PC/PP/HDPE/POM/PA6 GF/PVC/nylon/PMMA/PET, etc.

7. Zetarmold can also provide different surface treatments for injection molded parts.

8. The commonly used surface treatments for injection molded parts are: texture/sand/MT/YS/SPI/EDM smoothness/smoothness/gloss/VDI.

In addition to manufacturing injection molded parts, we also provide printing, welding, assembly, and packaging services.

Starting from the analysis of component design.

2. Provide mold design drawings and DFM reports so that you can understand the status of the mold before manufacturing.

If the product is complex, a moldflow report will also appear.

4. Ensure that the quality of your molds is well controlled in the indoor mold manufacturing workshop.

5. It usually takes 20-40 days to make a mold, and the exact time depends on the part design.

6. Injection molded parts can be made of different materials, such as ABS/PC/PP/HDPE/POM/PA6 GF/PVC/nylon/PMMA/PET, etc.

7. Zetarmold can also provide different surface treatments for injection molded parts.

8. The commonly used surface treatments for injection molded parts are: texture/sand/MT/YS/SPI/EDM smoothness/smoothness/gloss/VDI.

In addition to manufacturing injection molded parts, we also provide printing, welding, assembly, and packaging services.

Workflow after customer orders

Precision Engineering:

Using advanced design software such as CAD/CAM, UGS,and AutoCAD, our team ensures precise engineering and customization to meet specific user requirements, including those provided by customers.

Step 1: Analyze product drawings

Step 2: Create a manufacturable design

Step 3: Provide 3D samples for customer confirmation

Step 4: Conduct flow analysis inside the mold

Step 5: Mold Manufacturing

Step 2: Create a manufacturable design

Step 3: Provide 3D samples for customer confirmation

Step 4: Conduct flow analysis inside the mold

Step 5: Mold Manufacturing

Production Line

1: Workers with over 5 years of injection molding experience

2: First level Injection Molding Operation Certificate

3: Each production line is equipped with professional quality inspectors

2: First level Injection Molding Operation Certificate

3: Each production line is equipped with professional quality inspectors

Once the mold manufacturing is completed, we will make several pre production samples for testing. If the dimensions are correct, we will then send the samples to the customer for final confirmation. If the test fails, we will modify the mold or adjust the molding parameters to make a new sample, and then conduct the test again. Once the sample is approved by the customer, we will purchase the raw materials and conduct quality inspections. Then mix the materials, shape and trim them, and we will conduct multiple inspections during the production process. Finally, we will arrange for assembly and packaging. After the entire order is ready, we will send the packing list to the customer to arrange shipment.

Why Choose Us

Weifang Tenggu Intelligent Manufacturing Co., Ltd. has been focusing on plastic injection molds and molding series since its establishment.

We have a professional engineering team with over 5 engineers who specialize in plastic injection mold design, plastic injection molding processes, as well as printing, electroplating, and spraying processes.

Our company has an internal tooling workshop - a fully equipped tool room to ensure that you can make molds internally, provide free mold daily maintenance, and perform mold repair work when needed.

At the same time, we have 16 injection molding machines ranging from 100 tons to 1000 tons, which can produce parts from 0.01 pounds to 13 pounds.

We have a professional engineering team with over 5 engineers who specialize in plastic injection mold design, plastic injection molding processes, as well as printing, electroplating, and spraying processes.

Our company has an internal tooling workshop - a fully equipped tool room to ensure that you can make molds internally, provide free mold daily maintenance, and perform mold repair work when needed.

At the same time, we have 16 injection molding machines ranging from 100 tons to 1000 tons, which can produce parts from 0.01 pounds to 13 pounds.

Certifications

Exhibition

FAQ

1.Are you a trading company or a manufacturer?

We are a manufacturer, and you can see our workshop as described above. What kind of trade terms can you use?

When leaving the factory, FOB price, CIF price, DDP DDU

2.What are your payment terms?

50% mold cost deposit, 50% mold balance to be paid after first sample acceptance, product payment upon delivery

We accept wire transfers

3.Do you support OEM?

Yes, we can produce through technical drawings or samples.

4.What is your delivery time?

Generally, it takes 40 days (30 days for mold making and 10 days for mass production).

We are a manufacturer, and you can see our workshop as described above. What kind of trade terms can you use?

When leaving the factory, FOB price, CIF price, DDP DDU

2.What are your payment terms?

50% mold cost deposit, 50% mold balance to be paid after first sample acceptance, product payment upon delivery

We accept wire transfers

3.Do you support OEM?

Yes, we can produce through technical drawings or samples.

4.What is your delivery time?

Generally, it takes 40 days (30 days for mold making and 10 days for mass production).

Welcome to contact us: Phone: 0086-13564311131 Email: info @ zetarmald.com Website: //www.zetarmold.com |

Похожие товары

Хорошая цена расширяемая Форма для упаковки из пенополистирола

Yiwu ювелирная фабрика 9-дюймовая синяя резина/кремний A/B форма для 45% cad 55% цинковый сплав литье

13,00-20,00 $

Чугунная Форма цилиндра 100*200 мм для съемных пластиковых бетонных кубиков форма цилиндров

40,00-45,00 $

Высокая точность высокая эффективная штамповочная гибочная машина CNC пресс-форма гидравлическая

130,00-150,00 $

Различные виды линейной формы

Пластиковая Крышка для минеральной воды

20-летний опыт работы с откидной верхней крышкой создатель прессформы литья Производитель

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $