ЧПУ обработка железа на заказ Точность токарная 1214L/1215 сталь CNC стали

- Категория: >>>

- Поставщик: Shenzhen Huayisheng Precision Manufacturing Co. Ltd.Shenzhen Ltd.

Сохранить в закладки 1601353960981:

Описание и отзывы

Характеристики

Welcome to Huayisheng Precision Manufacturing

CNC Machining

We provide CNC machining services of any complexity for the production of both serial parts and prototypes.

CNC Turning

CNC turning is a CNC process where a cutting tool, a typically non-rotating component of the lathe or turning center, removes.

Product range:

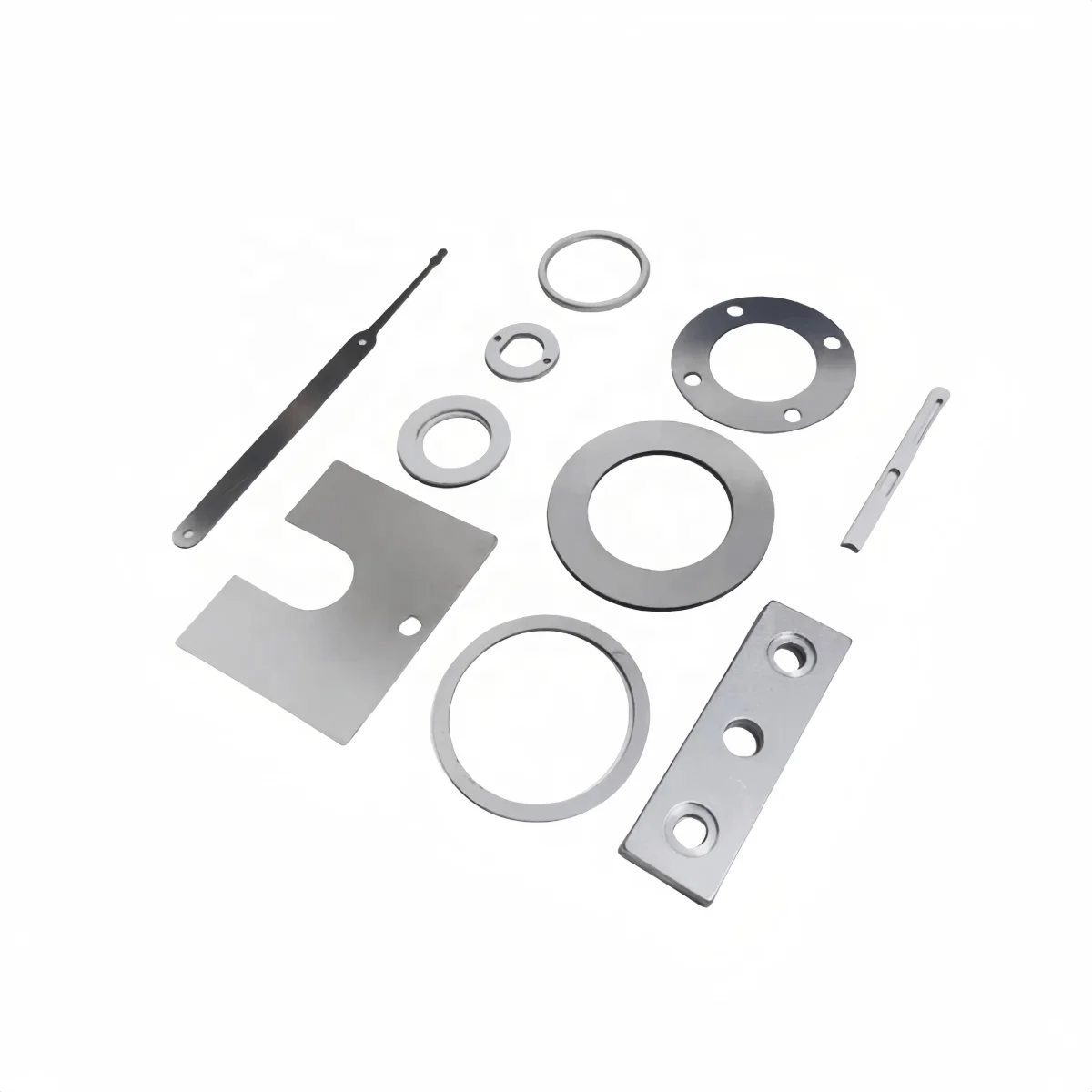

Our product range is extensive, including screws, nuts, springs, stamping parts, automotive lathe parts, CNCparts, computer gong parts and other metal products. Customers are welcome to provide drawings, concepts and samples or design and proofing.

⇒ ⇒ ⇒ Contact us for a quote

Customized services:

We are committed to providing production solutions for your design innovations and products, from

rapid part customization to one-stop service for small batch production.

rapid part customization to one-stop service for small batch production.

⇒ ⇒ ⇒ Click to buy samples

Design services:

Huayisheng Company has a group of professional engineering and technical personnel to provide professional suggestions during the design and production process, transform concepts into controlled products, solveprofessional problems for customers, and reduce production costs.⇒ ⇒ ⇒ Click for design services

Product Description

Product Name | wholesale turned mechanical precision lathe milling spare casting custom turning beryllium copper brass cnc machining parts | ||||||

Service | CNC Machining | ||||||

Turning and Milling | |||||||

CNC Turning | |||||||

OEM Parts | |||||||

Material | 1. Aluminum: AL 6061-T6, 6063, 7075-T etc | ||||||

2. Stainless steel: 303,304,316L, 17-4(SUS630) etc | |||||||

3. Steel: 4140, Q235, Q345B,20#,45# etc. | |||||||

4. Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | |||||||

5. Brass: C36000(HPb62), C37700(HPb59), C26800(H68), C22000(H90) etc | |||||||

6. Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |||||||

Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, | ||||||

Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |||||||

electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |||||||

Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |||||||

Main Equipment | STEP,STP,IGS,CAD,PDF,DWG,DXF etc or samples. | ||||||

Tolerance | +/-0.01mm ~ +/-0.05mm | ||||||

Surface roughness | Ra 0.1~3.2 | ||||||

Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM | ||||||

Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |||||||

Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm | ||||||

CNC milling work range: 510mm*1020mm*500mm | |||||||

Company Profile

Company Profile

Shenzhen Huayisheng Precision Manufacturing Hardware Co., Ltd. was established in 2013. The factory covers an area of more than 3,000 square meters and has more than 100 employees. The company has more than 30 high-precision CNC machining centers, more than 50 CNC lathes, and various types of Auxiliary equipment. Specializing in the R&D and production of precision parts in various industries, the products are widely used in aviation, high-speed rail, medical, automobiles, yachts, precision testing instruments, industrial equipment, photographic equipment, optical equipment, etc.

Company Profile

The company relies on its strict quality management system, advanced and complete production processes to accurately provide customers with reliable technical support. We continue to innovate and provide customers with performance products with an attitude of excellence from product design to parts production. And with its excellent reputation and service, it is deeply favored by customers at home and abroad. In line with the business philosophy of "integrity-based, quality assurance, service first", we continue to make progress and improve, and provide our customers with high-quality products and services. We sincerely look forward to comprehensive cooperation with our customer partners to create brilliance together!

conference room

operator

product

Certifications

FAQ

* Are you factory or trade company?

We are factory , so we can offer you very competitive price and very fast lead time, our samples lead time is 3-7 days. Mass production lead time is 15-20days.

* Whether some samples can be provided?

Yes,just need some samples cost, we will return it back when proceed into mass production

* Will my drawing be safe after you get it?

Yes,we will not release your design to third party unless with your permission

* How to deal with the parts received when they are found to be in poor quality?

Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance.in case Of non-conformanace,plase contact with us immediately,take some pictures, we will check on the problems and have them reworked or repaired at the first time with the Resulting transportation costs bome by our company

* Your company trade assurance?

Yes 100% ensure quality,100% ensure delivery time.

We are factory , so we can offer you very competitive price and very fast lead time, our samples lead time is 3-7 days. Mass production lead time is 15-20days.

* Whether some samples can be provided?

Yes,just need some samples cost, we will return it back when proceed into mass production

* Will my drawing be safe after you get it?

Yes,we will not release your design to third party unless with your permission

* How to deal with the parts received when they are found to be in poor quality?

Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance.in case Of non-conformanace,plase contact with us immediately,take some pictures, we will check on the problems and have them reworked or repaired at the first time with the Resulting transportation costs bome by our company

* Your company trade assurance?

Yes 100% ensure quality,100% ensure delivery time.

Похожие товары

OEM латунная обработка с ЧПУ деталей из нержавеющей стали и железа поворотное фрезерование штамповка услуги

1,00-5,00 $

Индивидуальная обработка с ЧПУ для прецизионных деталей из алюминиевого сплава нержавеющая сталь медь железо другие услуги по обработке металлических материалов

6,00 $

304 обработка нержавеющей стали токарный станок с ЧПУ Обработка Нестандартных Деталей Оборудования из алюминиевого сплава прецизионная

Высококачественная 3D-печать высокопрочная на заказ высокоточная 3D-смола 3D % e6 89% 93% e5 8d b0 услуга 3D-печати

3,00-4,00 $

Производитель высококачественные автозапчасти Левая Правая сторона руль OEM 2513300703 2513300803 для W251/R350

23,00-25,00 $

Тяжелые индивидуальные детали для поворота с ЧПУ внутренняя Резьбовая цилиндрическая прямая Соединительная штанга

Хорошее качество рулевая тяга Левая Правая OEM 1643301103 1643301203 для W164

23,00-25,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $