Высокопрочная линейная направляющая с ЧПУ

- Категория: >>>

- Поставщик: Shandong Jieyin Electromechanical Technology Co. Ltd.Shandong Ltd.

Сохранить в закладки 1601354217838:

Описание и отзывы

Характеристики

Linear guide rail is a kind of mechanical transmission element that moves by sliding load on the guide rail. It consists of slider, guide rail and ball. The slider is equipped with balls, which slide on the guide rail by rolling, so that the guide rail has high-precision linear motion. The slider and guide rail are usually made of high-strength alloy steel or S55C carbon steel. Through precise machining and heat treatment, their surfaces have high hardness and low friction coefficient. This design makes the linear guide rail have the characteristics of high positioning accuracy, high speed and wear resistance

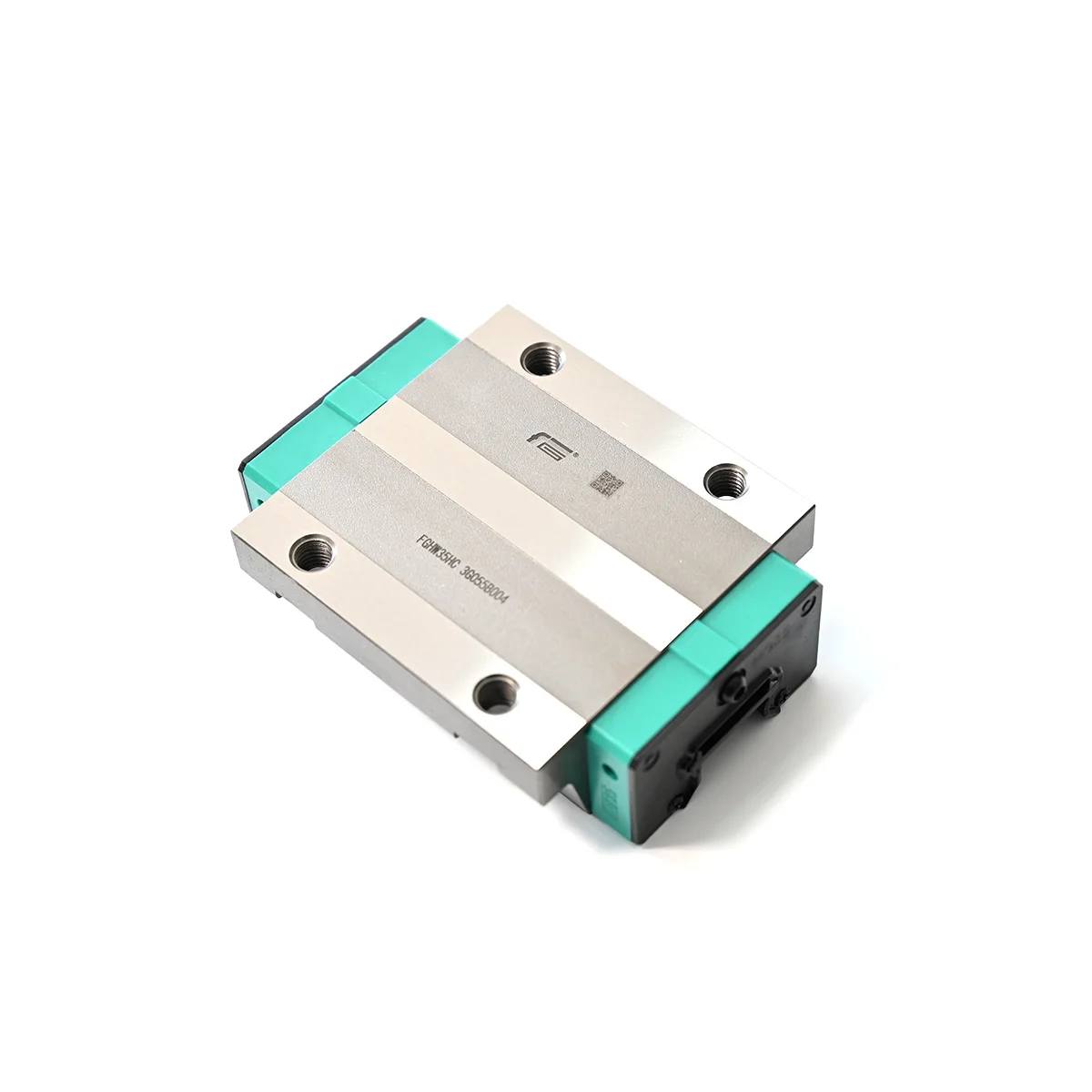

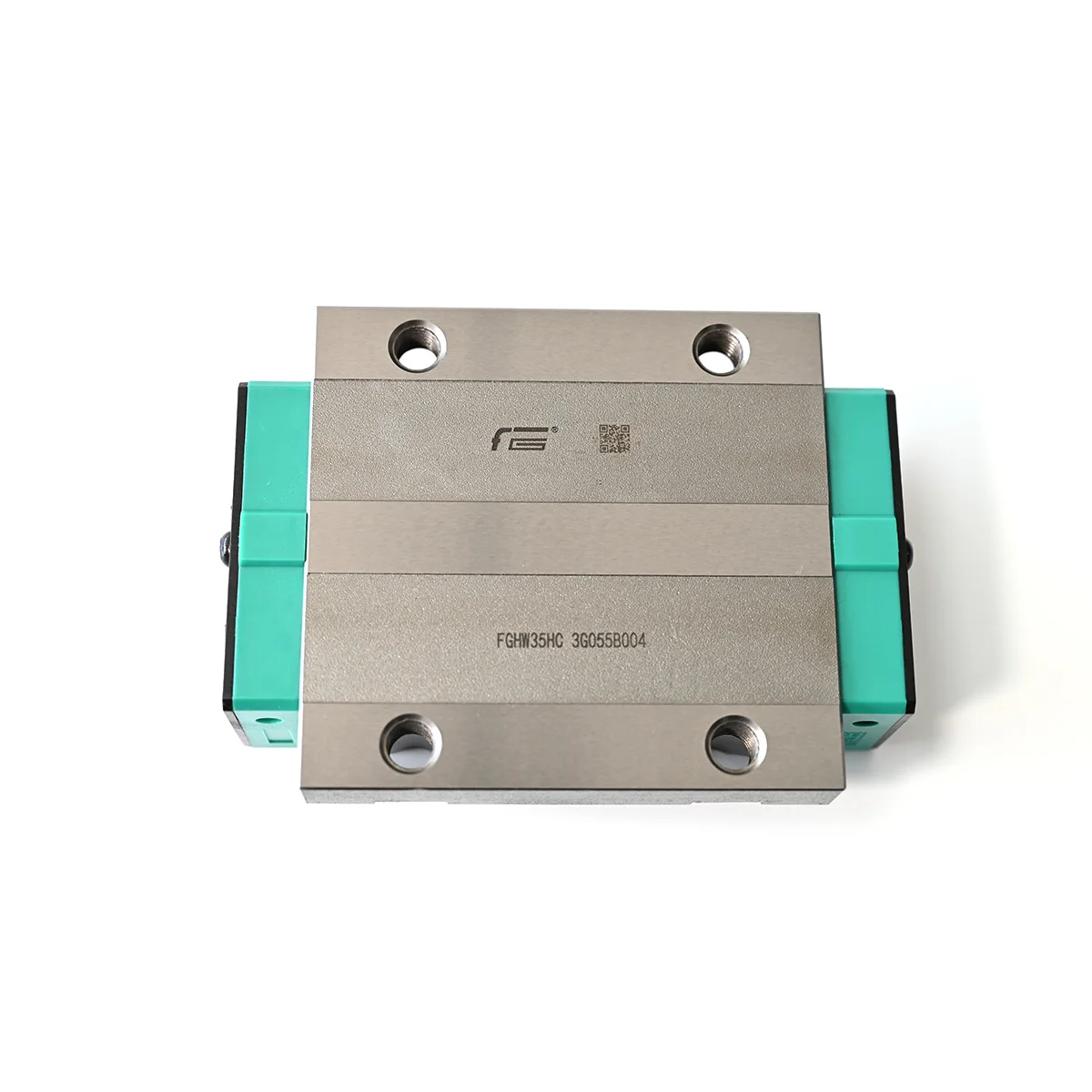

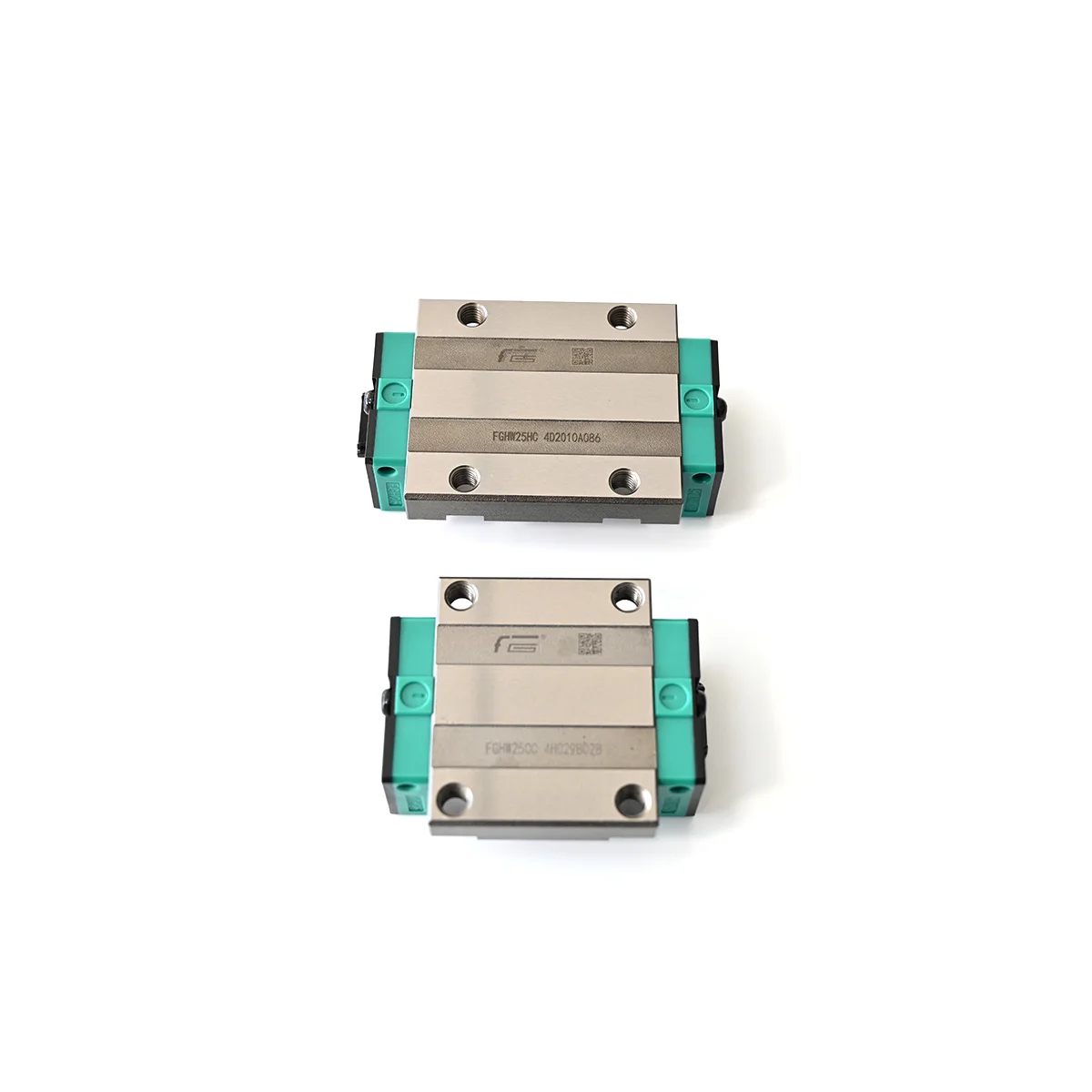

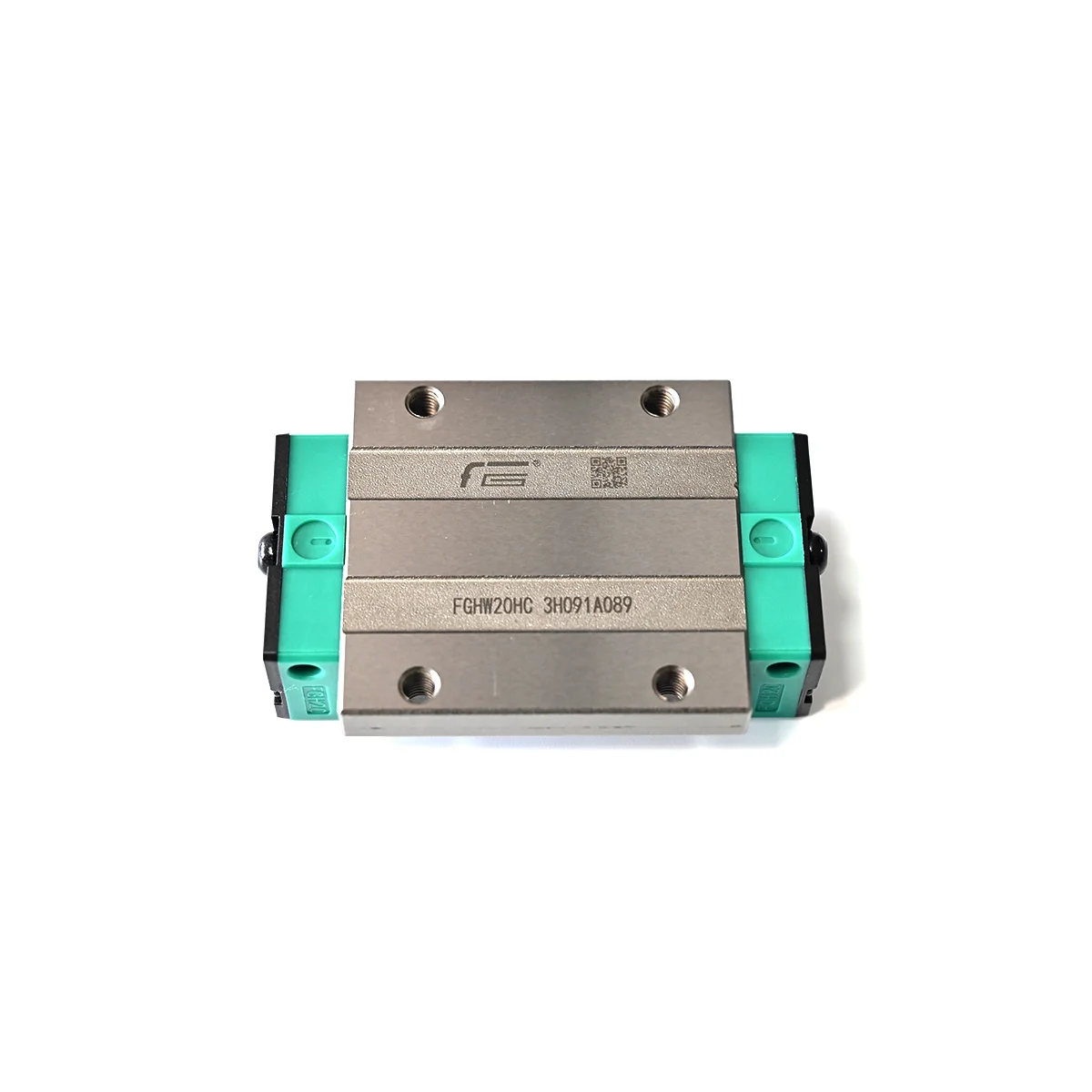

| specifications | FGHW35HC | |||||

| Slider material | SCM420H alloy steel | |||||

| Linear guide rail material | S55CCarbon Steel | |||||

| Sliding block type | Flange overload | |||||

| accuracy class | C | |||||

| advantage | Four-row single circular arc tooth contact linear guide rail, and at the same time integrate the heavy-duty precision linear guide rail with optimized structural design, which improves the load and rigidity ability; It has the characteristics of four-direction equal load and the function of automatic centering, which can absorb the assembly error of the installation surface and obtain the requirement of high precision. | |||||

| precompaction | Custom-defined, can accept multi-segment splicing. | |||||

| Precompression | 0~0.02C | |||||

| Application | Conveying device, automatic packaging machine, automatic industrial machinery, XY axis of general industrial machinery, welding machine, fusing machine, tool exchange device | |||||

Shandong Jieyin Electromechanical Technology Co., Ltd. was established on November 4, 2014, located in Jinan City, Shandong Province. The company focuses on the mechanical transmission industry and is a comprehensive company that integrates production and sales. Its products include slides, screws, modules, racks, etc. Our company is a strong agent of Fulei brand, adhering to the service concept of "customer first", serving every customer with heart, resolutely implementing product quality, strictly controlling high requirements, and striving to provide customers with convenient, fast, high standard and high-quality services.

We firmly believe that quality creates a brand, and integrity shapes the future

Our vision is to make the company a leading and world-class revitalized enterprise in the industry

Let all customers benefit from the company

Benefit all employees from the company

Please refer to FGHW35HC for detailed data size

| Usage of linear guide rail | ||||||

| (1) clamp fixation method The side surfaces of the slide rail and slider should slightly protrude from the edges of the bed and workbench, and the pressure plate should be machined with escape grooves to prevent interference with the corners of the slide rail or slider during installation. |  | |||||

| (2) Push-pull fixation method Pressure is exerted by locking the push and pull. Excessive locking force will easily cause the slide rail to bend or the outer shoulder to deform, so special attention should be paid to the appropriateness of locking force during installation. |  | |||||

| (3) Roller fixing method The roller is pressed by the advance of the slope of the bolt head, so pay special attention to the position of the bolt head. |  | |||||

| (4)Positioning bolt fixing method Because of the limitation of installation space, the size of bolts used should not be too large. |  | |||||

Похожие товары

FGHW20CC фланец Расширенный слайдер высокая жесткая ЧПУ промышленное линейное направляющее сиденье Высокая сборка Бестселлер Быстрая доставка

Комплект подшипников линейного подшипника с изогнутой направляющей

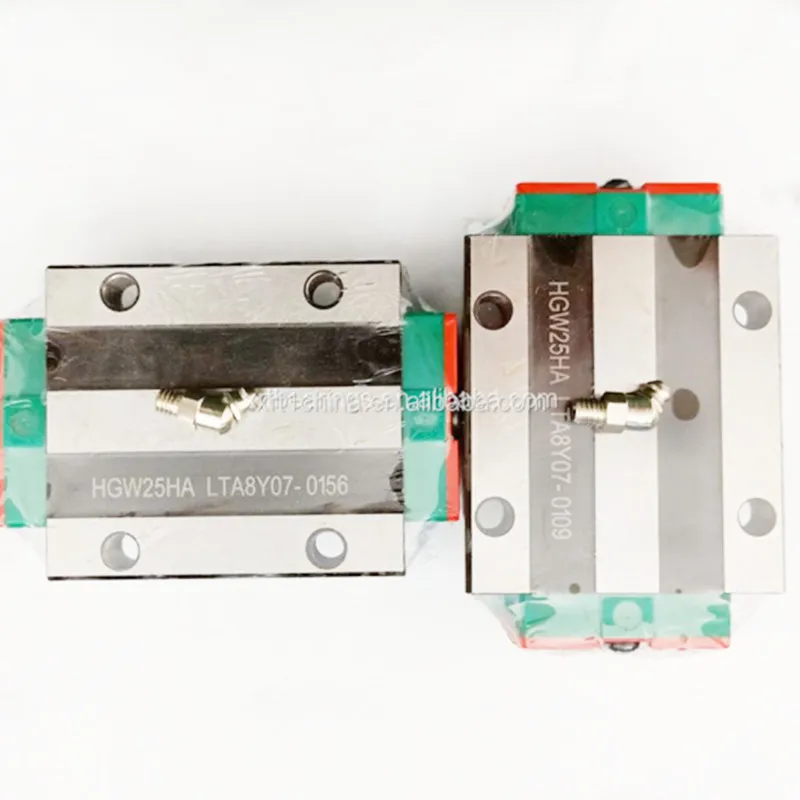

Оригинальный HIWIN линейный направляющий блок HGW25 HGW25CC hgw25cccz0h

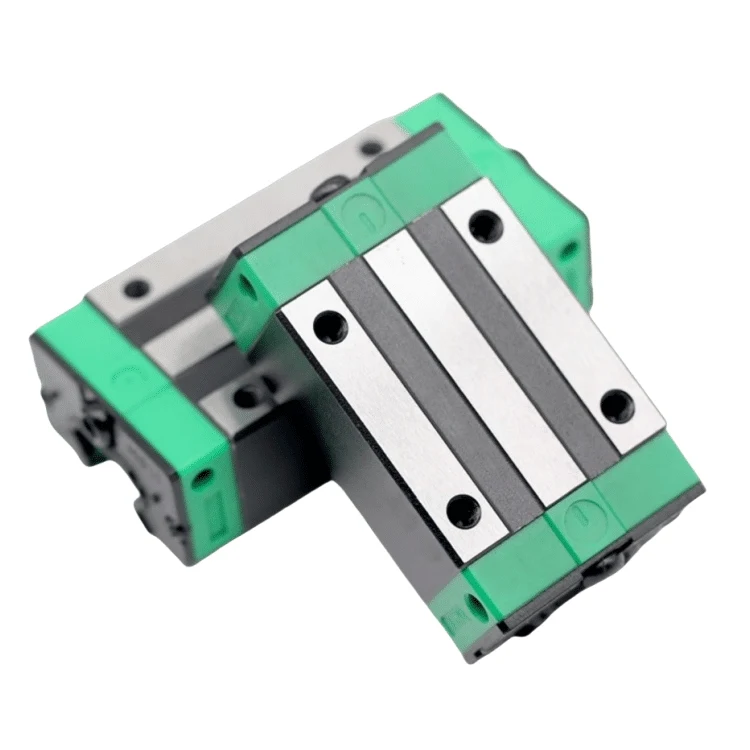

ULC35 ULC28 ULC18 TLV63 TLV43 TLV35 TLV28 TLV18 TLC63 100% оригинальные итальянские роликовые линейные подшипники с ЧПУ

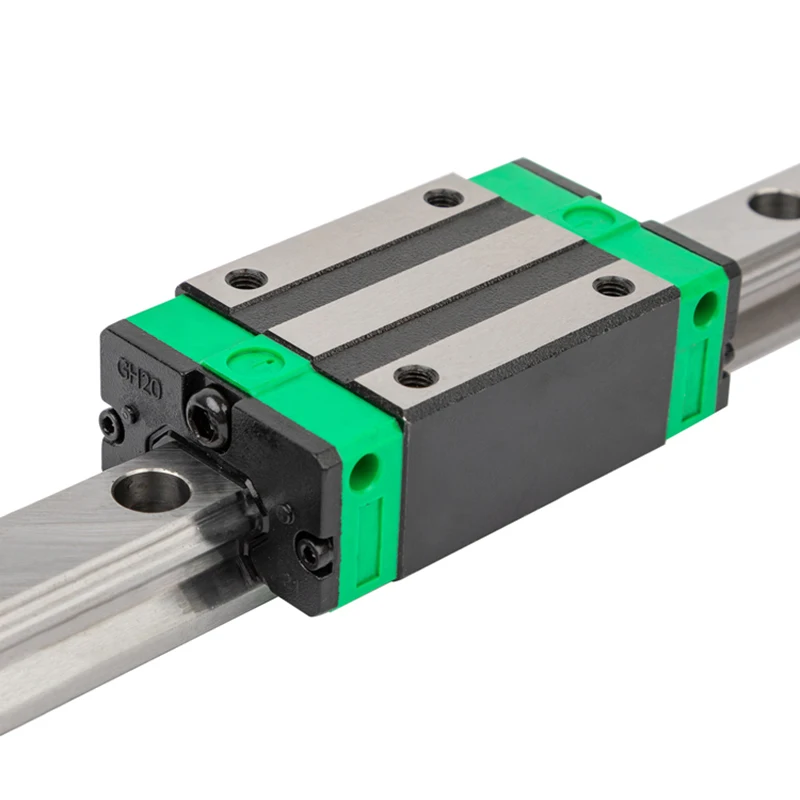

Линейная направляющая GH15 GH20 и блок ходовой рейки

Professional SHAC Linear Block - Ensure Precise Movement

Низкая цена Япония SHW12HRM SHW14CRM SHW17CRM shw45c1uu (GK) SHS45-2310L SHS45-1020L NART 50R линейный блок с ЧПУ

Новые поступления

Новинки товаров от производителей по оптовым ценам